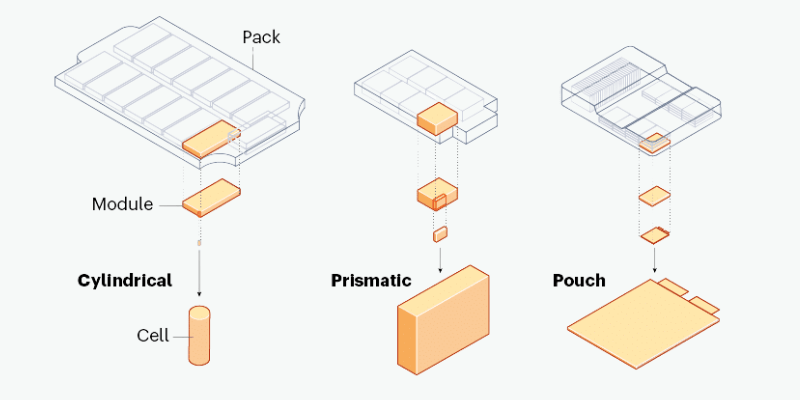

Å forstå forskjellene mellom battericeller, moduler og pakker er avgjørende for å designe effektive energilagringssystemer. Denne artikkelen utforsker deres konstruksjon, ytelsesegenskaper og applikasjoner.

Battericelle

Hva er en battericelle?

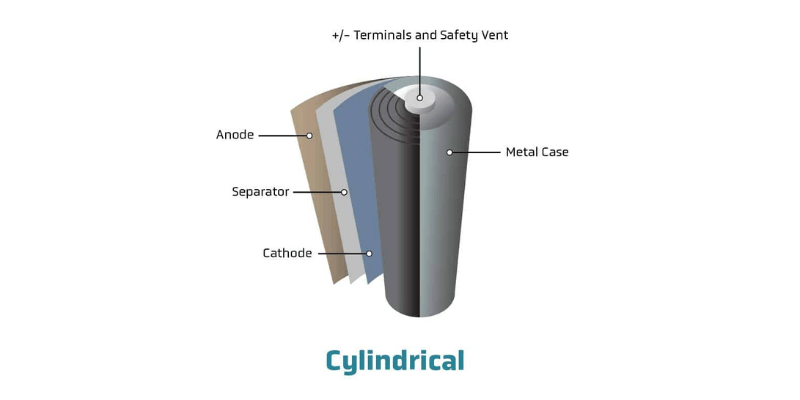

En battericelle er den grunnleggende enheten til et batteri, og fungerer som en liten beholder som lagrer og frigjør elektrisk energi gjennom kjemiske reaksjoner. Den består av elektroder (anode og katode) atskilt med en elektrolytt og innelukket i et kabinett. Flere celler kan kombineres for å danne et større batteri med høyere spenning eller kapasitet.

Battericelledesign

Størrelse

Battericeller spenner fra små i elektronikk til store celler i elektriske kjøretøy, noe som påvirker kapasitet og energitetthet for spesifikke bruksområder.

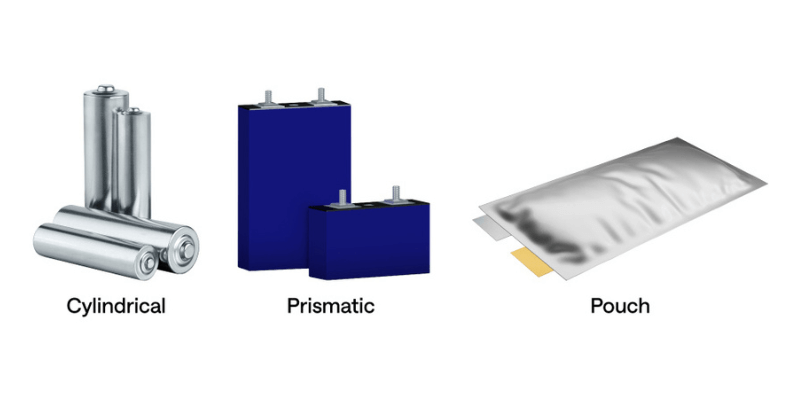

Form

Battericeller kommer inn sylindrisk, prismatisk, og veskedesign.

Sylindriske celler:

- Fordeler: Robust, jevn ytelse, høy energitetthet.

- Ulemper: Lavere spesifikk energitetthet enn noen formater.

- Bruksområder: Bærbare datamaskiner, elektroverktøy, bærbar forbrukerelektronikk

Poseceller:

- Fordeler: Høy energitetthet, fleksibel design, kostnadseffektiv.

- Ulemper: Fare for hevelse, krever nøye termisk håndtering.

- Applikasjoner: Smarttelefoner, nettbrett

Prismatiske celler:

- Fordeler: Høy energitetthet, effektiv termisk styring, skalerbar design.

- Ulemper: Mindre fleksibilitet enn poseceller.

- Bruksområder: Elektriske kjøretøy, energilagringssystemer, industrielle applikasjoner.

Intern kjemi

En battericelles interne kjemi bestemmer ytelsen, inkludert spenning, kapasitet og syklusliv. Ulike kjemier, som litium-ion, nikkel-metallhydrid og blysyre, tilbyr varierende avveininger i energitetthet, kostnader og sikkerhet. For eksempel er litium-ion foretrukket for sin høye energitetthet i bærbare enheter.

Elektrodematerialer

Elektrodematerialer påvirker battericellenes ytelse og levetid betydelig. Vanlige alternativer inkluderer litiumkoboltoksid (LiCoO2), litiumjernfosfat (LiFePO4) og nikkelmangankoboltoksid (NMC). Hver tilbyr distinkte energitetthet, stabilitet og sikkerhetsprofiler skreddersydd for spesifikke behov.

Emballasje og innkapsling

Battericeller er plassert i beskyttende emballasje for å forhindre skade fra miljøfaktorer. Emballasjen må gi isolasjon for å unngå elektrolyttlekkasje samtidig som den sikrer langsiktig pålitelighet; riktig innkapsling tar også opp risikoer som termisk løping eller kortslutninger.

Vanlige emballasjematerialer inkluderer:

- Metallbokser: Disse beskytter sylindriske celler og forhindrer kortslutning.

- Aluminiumsposer: De tilbyr et fleksibelt, lett kabinett for poseceller.

- Metallhus: Disse beskytter prismatiske celler og hjelper til med termisk styring.

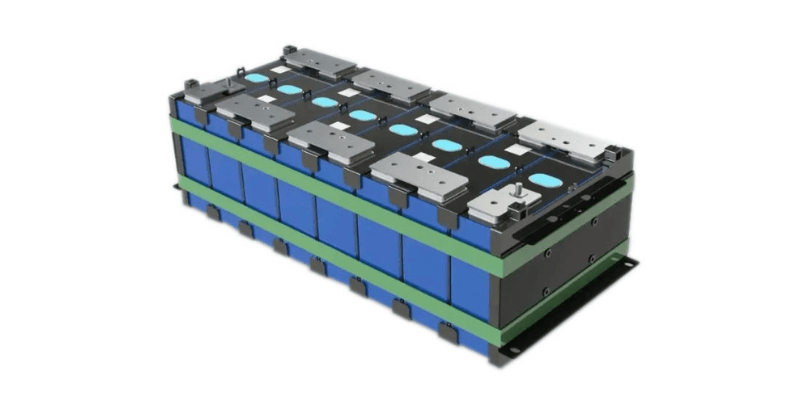

Batterimodul

Hva er en batterimodul?

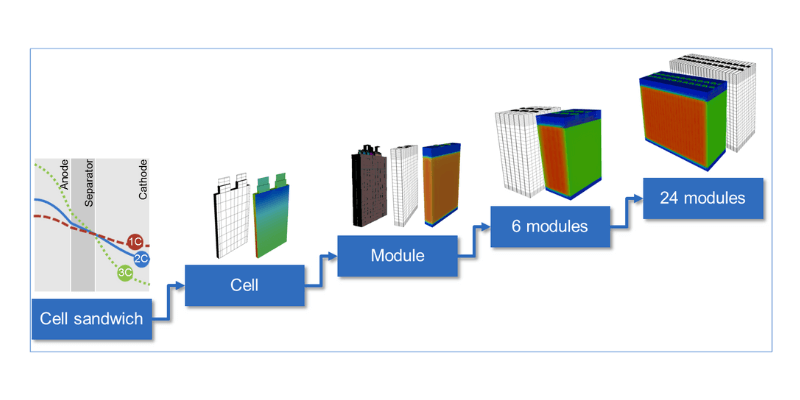

En batterimodul består av tilkoblede battericeller plassert i ett kabinett. Det øker spenningen og kapasiteten til et batterisystem, og fungerer som en kobling mellom individuelle celler og hele batteripakken.

Batterimoduldesign

Størrelse og form

Batterimodulens størrelse og form varierer basert på bruksområde og ønsket energieffekt. Vanlige konfigurasjoner inkluderer:

- Moduler av posetype: Fleksible og lette, brukt i forbrukerelektronikk og elektriske kjøretøy.

- Prismatiske moduler: Stive og stablebare, ofte funnet i elektriske kjøretøy og energilagringssystemer.

- Sylindriske moduler: Laget av sylindriske celler, som tilbyr høy energitetthet og mekanisk robusthet.

Intern kjemi og elektrodematerialer

Battericellenes kjemi og materialer påvirker den generelle ytelsen. Nøkkelfaktorer inkluderer:

- Anodematerialer: Vanlige alternativer er grafitt, silisium og litiumtitanatoksid (LTO), som hver tilbyr unike fordeler.

- Katodematerialer: Litiumkoboltoksid (LCO), litiummanganoksid (LMO), litiumjernfosfat (LFP) og nikkel-kobolt-aluminiumoksid (NCA) er forskjellige i energitetthet, effekttetthet og sykluslevetid.

- Elektrolytt: Vanligvis en væske eller fast stoff som letter ionebevegelse mellom anoden og katoden.

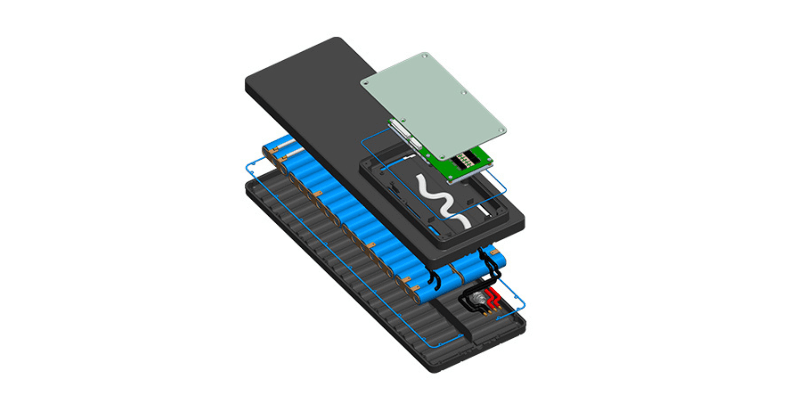

Emballasje og innkapsling

Modulens emballasje beskytter interne komponenter samtidig som den sikrer sikkerhet. Viktige hensyn inkluderer:

- Modulhus: Det skal være sterkt, kjemisk motstandsdyktig og varmeledende.

- Cellesammenkobling: Pålitelige ledningsteknikker er avgjørende for celletilkoblinger.

- Termisk styring: Forhindrer overoppheting ved bruk av kjøleribber eller faseendrende materialer.

- Sikkerhetsfunksjoner: Inkluder sikringer, kretsbrytere eller trykkavlastningsventiler for å redusere risikoen.

Batteristyringssystem (BMS)

En BMS er et must for overvåking av parametere som:

- Cellespenning: Sikrer jevn lading og utlading på tvers av celler.

- Celletemperatur: Forhindrer overoppheting eller overdreven avkjøling.

- Ladetilstand (SOC): Sporer gjenværende kapasitet.

- Helsetilstand (SOH): Anslår batterilevetid.

Batteripakke

Hva er en batteripakke?

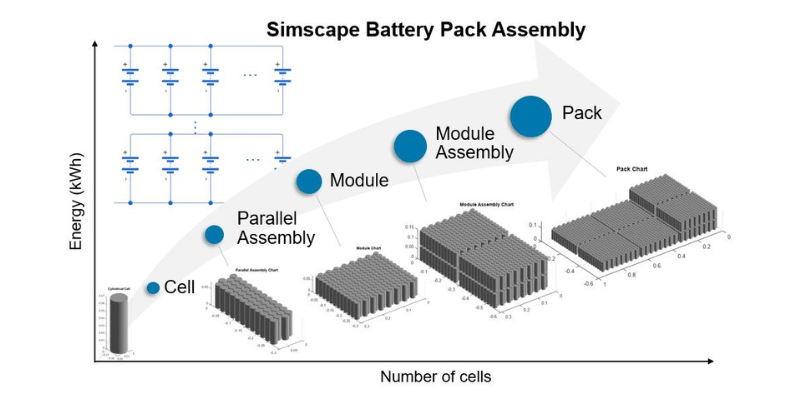

En batteripakke består av battericeller eller moduler koblet til en enkelt strømkilde. Celler er ordnet i serie og parallell for å oppnå ønsket spenning og strøm. Batteripakker kan inneholde én eller tusenvis.

Batteripakkedesign

Battericellearrangement:

- Bestem nødvendig spenning og kapasitet.

- Velg battericelletype og størrelse (f.eks. litiumion, litiumpolymer) basert på ytelsesbehov.

- Bestem deg for serie- og parallellkonfigurasjoner for å oppnå ønsket spenning og kapasitet.

- Sørg for enhetlighet i cellespesifikasjoner for å opprettholde balansen.

Husdesign:

- Velg materialer til batteripakken som sikrer styrke, holdbarhet og effektiv termisk styring.

- Design huset for å romme battericeller effektivt. Inkluder kjøleventiler, kjøleribber eller isolasjon for temperaturregulering.

- Beskytt cellene mot fysisk skade og miljøfaktorer som fuktighet og støv.

Sikkerhetsfunksjoner:

- Integrer en BMS for å overvåke lading, utlading og temperatur.

- Inkluder beskyttelse for overlading, overutlading, kortslutninger og termisk løping.

- Installer sikringer eller effektbrytere for nødisolasjon.

- Sørg for samsvar med UN/DOT-forskrifter og UL-sertifiseringer.

Elektriske tilkoblinger:

- Design elektriske forbindelser med lav motstand mellom celler/moduler/terminaler for å minimere energitapet.

- Bruk materialer av høy kvalitet for pålitelige tilkoblinger som reduserer spenningsfall eller feil.

- Implementer isolasjon og skjerming for å forhindre buedannelse, korrosjon og elektromagnetisk interferens.

Testing og validering:

- Gjennomfør grundig testing av designytelse under ulike forhold.

- Utfør stresstester som temperatursykling, vibrasjonstesting; vurdere holdbarhet.

- Valider samsvar med industristandarder gjennom strenge testprotokoller.

Batteripakkeapplikasjoner

- Bærbar elektronikk: Batteripakker gir strøm til mobile enheter som smarttelefoner, nettbrett og bærbare datamaskiner, og tilbyr praktiske løsninger på farten.

- Elektriske kjøretøy: Batteripakker er den primære energilagringen i elbiler, og gir fremdriftskraft for utslippsfri transport.

- Stasjonær energilagring: Batteripakker lagrer overflødig energi fra fornybare kilder som solenergi og vind, noe som muliggjør reservekraft, stabilisering av nett og lastforskyvning.

Hva er forskjellen mellom battericelle, batterimodul og batteripakke?

For å forstå forskjellene mellom battericeller, moduler og pakker, la oss bryte ned hver komponent:

- Battericelle: Den grunnleggende enheten for energilagring som konverterer kjemisk energi til elektrisk energi. Den kommer i forskjellige former (sylindrisk, prismatisk eller pose) og inneholder en anode, katode, separator og elektrolytt.

- Batterimodul: En gruppe sammenkoblede battericeller som øker spenning og kapasitet sammenlignet med individuelle celler. Den inkluderer ledninger og kontakter og kan ha et grunnleggende batteristyringssystem (BMS) for overvåking.

- Batteripakke: Et komplett energilagringssystem som inneholder en eller flere moduler. Den inkluderer et avansert BMS for cellebalansering, temperaturkontroll og sikkerhetsfunksjoner, samt tilleggskomponenter som hus og termiske styringssystemer.

Sammendrag:

- Battericelle: Den minste enheten.

- Batterimodul: En gruppe tilkoblede celler.

- Batteripakke: Et komplett system med moduler og en BMS.

Analogi:

- Battericelle: En enkelt murstein.

- Batterimodul: En vegg laget av flere murstein.

- Batteripakke: En bygning laget av flere vegger.