Returgodkjenninger for varer (RMA) reflekterer kundens misnøye og kan indikere problemer som produksjonsfeil eller kommunikasjonsfeil. Vi står bak produktet vårt og er klare til å støtte våre kunder.

Når kunder finner at de kjøpte varene er ubrukelige, kan de slite med å oppfylle sine egne forpliktelser. Selv om noen skeptikere ser på returer som egoistiske, antyder innsatsen som er involvert i å returnere et produkt at vi bør ta klagene på alvor.

Våre RMA-er deler én felles tråd

Customers request an RMA because they need our assistance, even if the product meets specifications or the damage was self-induced. An RMA indicates the customer requires help understanding or resolving an issue.

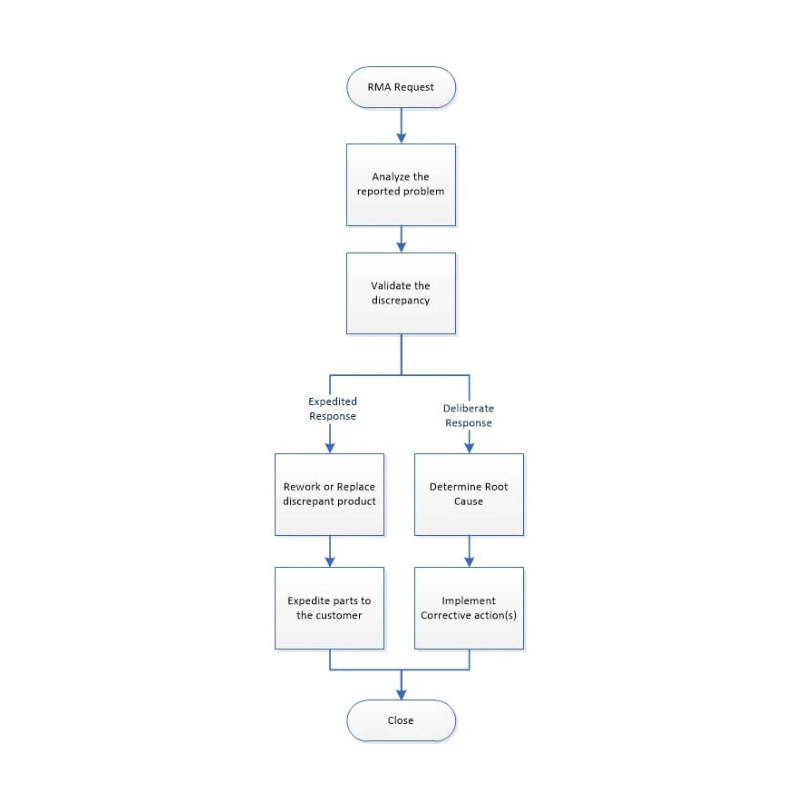

When customers cannot use our products, they rely on us to address their concerns. Upon receiving returns, we:

1. Confirm it’s a product we manufactured.

2. Validate the reported issue. Sometimes validation is quick; other times, laboratory analysis is needed to determine the failure mode and cause of defects.

Our first priority in RMA situations is to restore functioning parts for customers. Once we identify the failure mode, we conduct a Root Cause Analysis (RCA).

Importance of a Root Cause Analysis

Å identifisere og adressere årsaken til et problem er avgjørende for langsiktige løsninger. ASQ beskriver grunnårsaken som “ondskapen i bunnen” som utløser hele årsak-virkning-kjeden. Å fikse årsaken kan forhindre at problemer gjentar seg. Selv om lærebøker kan forenkle å finne det, innebærer det i praksis ofte en kompleks reise. Denne kompleksiteten kan føre til at organisasjoner hopper over grundig rotårsaksanalyse (RCA), og velger raske løsninger i stedet.

Raske svar på umiddelbare problemer kan virke kundefokusert, men uten å forstå grunnårsaken kan disse handlingene mangle bærekraft.

Dette kan resultere i scenarier der:

- Sjefen velger korrigerende handlinger ensidig.

- En dominerende personlighet styrer beslutninger uten konsensus.

- Lag blir fastlåst over diskusjoner uten å bli enige om effektive handlinger.

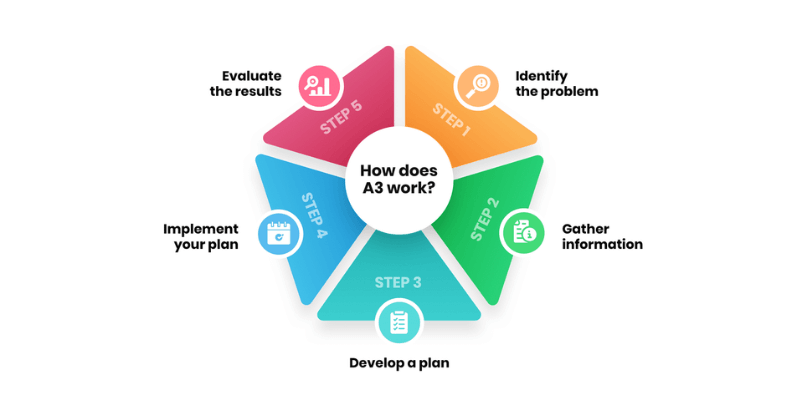

Strukturert problemløsning

Vi bruker strukturerte problemløsningsmetoder for å identifisere rotårsaker, og trener teamet vårt i Fem-Hvorfor metode og A3 prosess. Å etablere en rotårsak krever disiplin og fokus, men øvelse gjør det raskere.

Team sliter ofte med å komme til en konklusjon i konferanserom. Å finne årsaken krever vanligvis en tur til gemba, “stedet hvor det skjer,” og innebærer kontinuerlig å revurdere fakta i lys av teamets innsikt og meninger.

Kundetilfredshet

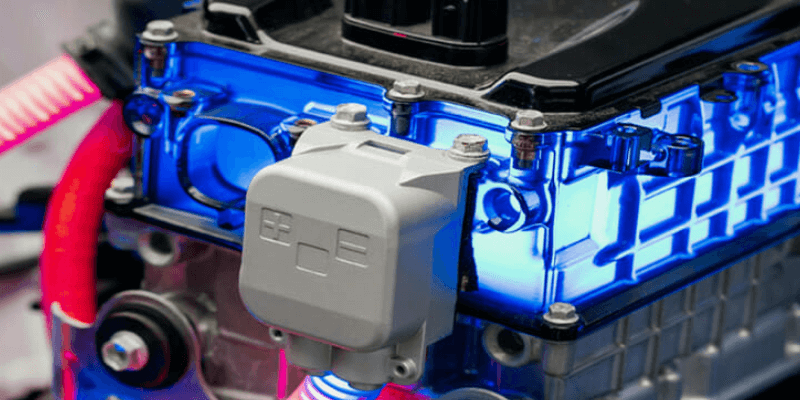

Hos Holo Battery søker vi aktivt tilbakemeldinger fra kunder for å skreddersy produktene og tjenestene våre. Vi etablerer dialog gjennom kundebesøk, fabrikkrevisjoner og prosjektmøter. Denne tilbakemeldingen er avgjørende for vår strategiske planlegging og operasjonelle forbedringer.

Videre er overvåking av tilbakemeldinger fra kunder avgjørende for virksomhetens helse og er et krav i ISO 9001 kvalitetsstyringssystemet. Avsnitt 8.2.1 sier at organisasjoner skal overvåke informasjon om hvorvidt de har oppfylt kundekrav.

Konklusjon

Et RMA-produkt utløser en kjede av hendelser, som understreker viktigheten av en effektiv RMA-prosess. Først må du erstatte det umiddelbart med et funksjonelt produkt. Analyser deretter feilen i å identifisere årsaken. Etter å ha identifisert problemet, ta skritt for å rette opp det og forhindre gjentakelse. Denne systematiske tilnærmingen legger til rette for kontinuerlig forbedring og overgår ofte kundenes forventninger.