Die Sicherheit von Batterien auf Lithiumbasis wurde intensiv untersucht und zeichnete Parallelen zu historischen Energiespeicherrisiken wie Dampfmaschinenexplosionen und frühen Benzin -Kontroversen. Während die Lithium-Ionen-Technologie im Allgemeinen sicher ist, heben gelegentliche Misserfolge wie der Sony-Rückruf von sechs Millionen Packungen von 2006 potenzielle Risiken hervor.

Die Batteriehersteller wollen Metallpartikel reduzieren, die sich trotz der Herausforderungen bei der Aufrechterhaltung der absoluten Sauberkeit in Batterienräumen ausgelöst haben. Zellen mit ultradünnen Separatoren (24 uM oder weniger) sind anfälliger für Verunreinigungen als ältere Konstruktionen. Während sie sich entzünden können, haben sich neue Sicherheitsstandards durch UL entwickelt, die keine Penetrationstests für die Annahme von Lithiumbatterien mehr benötigen.

Um die Sicherheit vor der Veröffentlichung zu gewährleisten, unterwerfen sich Hersteller Batterieproben zu strengen Tests, die über ein Jahr eine Million fehlerfreier Proben erfordern, bevor kritische Anwendungen wie medizinische Geräte genehmigt werden.

Da die derzeitige Li-Ionen-Technologie ihren Energiekapazitätsgrenzen nähert, priorisieren die Hersteller die Sicherheits- und Langlebigkeitsverbesserungen vor der bloßen Kapazität. Die Herausforderungen bestehen bei internen Kurzkreisen, die externe Schutzmaßnahmen überwältigen können, wie der Rückruf von 2006 zeigt, der die Sicherheitsanforderungen der UL entspricht, während sie während des normalen Gebrauchs jedoch noch fehlten.

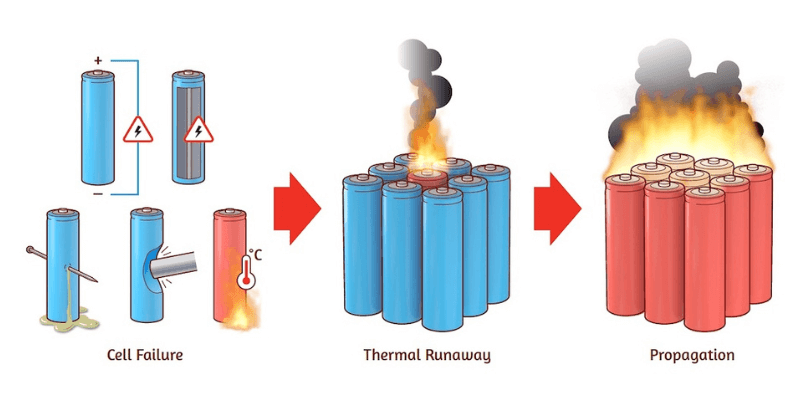

Batterieausfälle fallen in zwei Kategorien: vorhersehbare Designfehler und zufällige Ereignisse ohne klare Designprobleme. Ein kleiner Kurzfilm kann mit minimalem Wärmeanbau eine erhöhte Selbstentladung verursachen. Eine Akkumulation von metallischen Partikeln kann jedoch zu einem signifikanten Stromfluss und einer übermäßigen Erwärmung führen, die möglicherweise verursacht werden thermisches Durchgehen, oft beschrieben als als “mit Flamme entlüften.”

Darüber hinaus erhöhen ungleichmäßige Separatoren den Widerstand und erzeugen lokale Wärmeflecken, die die Integrität des Separators schwächen. Am meisten Hauptli-Ionen-Hersteller Röntgenaufnahme jeder Zelle während der Qualitätskontrolle, um Anomalien wie gebogene Registerkarten oder zerkleinerte Gelee-Rollen zu erkennen – Beitrag zu den heutigen Sicherheitsstandards von Batterie, die normalerweise nur von anerkannten Marken bestätigt werden.

Vorrückung der Sicherheit von Lithium-Ionen-Batterie: Schlüsselüberlegungen

Qualitäts-Lithium-Ionen-Batterien sind von Natur aus sicher, wenn sie korrekt verwendet werden. In Konsumgütern mit nicht zertifizierten Batterien wie Hoverboards wurden jedoch zahlreiche Wärme- und Brandvorfälle gemeldet. Diese Probleme wurden in jüngsten Modellen weitgehend mit zertifizierten Li-Ionen-Batterien gelöst.

Missbrauch, wie z. B. Exposition gegenüber extremen Bedingungen oder Überladung, kann zu allen Batterie -Typen zu Fehlern führen, wodurch die Notwendigkeit ordnungsgemäßer Handhabungspraktiken betont wird. Li-Ionen-Zellen erfordern eine sorgfältige Behandlung, um Instabilität zu verhindern, einschließlich der Vermeidung von tiefen Entladungen und einer längeren Exposition mit niedriger Spannung. Wärme und Überladung sind Hauptstressoren für Li-Ionen-Batterien, die vorsichtige Speicherpraktiken wie teilweise Ladung und Schutz vor direktem Sonnenlicht erfordern. Hersteller tragen die Verantwortung für Batterieausfälle und unterstreichen ihr Engagement für Sicherheitsstandards trotz seltener Vorfälle bei der täglichen Nutzung des Geräts.

Trotz der täglichen Verwendung von über einer Milliarde mobile Geräte bleiben Unfälle selten – Weniger als ein Misserfolg pro Million für Qualitätsli-Ionen-Zellen im Vergleich zu einer 1 von 13.000 Chance, über ein Leben lang von Blitz getroffen zu werden.

Industrielle Batterien, die in Elektrowerkzeugen verwendet werden, sind in der Regel robuster als Verbrauchermodelle, konzentrieren sich jedoch eher auf die Stromversorgung als auf lange Laufen. Leistungszellen sind sicherer, wenn sie im Vergleich zu Energiezellen missbraucht werden.

In den letzten Jahren haben Bedenken Risiken hervorgehoben, die mit unbekannten Markennamen Lithium-Ionen (18650) im Zusammenhang mit dem Dampfen verwendet werden. Diesem fehlt möglicherweise die Qualitätssicherung, die in seriösen Marken zu finden ist. Brände von fehlerhaften E-Zigaretten-Batterien haben zu gefährlichen Vorfällen geführt, wie eine Notlandung eines Westjet-Flugs aufgrund eines an Bord befindlichen Brandes, der durch den illegalen Batterietransport verursacht wurde.

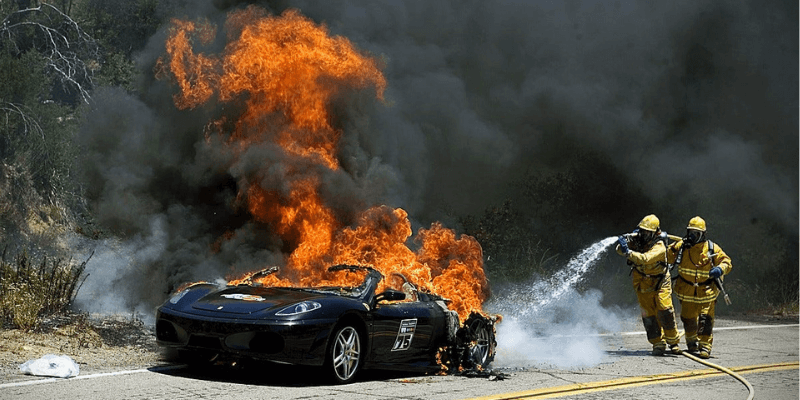

In Bezug auf Elektrofahrzeuge (EVs) zeigen Statistiken, dass sie im Vergleich zu Verbrennungsmotoren (ICE) weniger Brände pro Milliarde Kilometer produzieren: etwa zwei Brände pro Milliarde Kilometer für Tesla gegenüber rund 90 für Eisfahrzeuge, nachdem über 400.000 Eiswagen in den 80ern Feuer gefangen wurde.

Was tun, wenn eine Batterie überschwächt oder Feuer fängt

Während eines Überhitzungsvorfalls von Li-Ionen-Batterie ist eine schnelle Aktion von entscheidender Bedeutung. Wenn die Batterie zischt oder sich zahlt, bewegen Sie das Gerät auf eine nicht geschlossene Oberfläche und erwägen Sie es im Freien. Das einfache Trennen der Batterie reicht möglicherweise nicht aus, um weitere Probleme zu vermeiden.

Verwenden Sie für kleine Li-Ionen-Brände Schaum, CO2, Trockenchemikalien, Graphitpulver, Kupferpulver oder Soda-Löscher. In Flugzeugkabinen können Flugbegleiter aufgrund des niedrigen Lithiumgehalts in den Batterien Wasser oder Soda verwenden, um Li-Ionenbrände zu verwalten.

Ladungsbereiche sind mit Brandunterdrückungssystemen wie Halon ausgestattet, um neben anderen brennbaren Materialien Li-Ionen-Brände zu verwalten. Neue Löschmethoden wie wässrige Vermiculit -Dispersion (AVD) und Extover® bieten innovative Möglichkeiten, um brennende Batterien zu ersticken. Sand in feuerfesten Behältern kann auch Verbrennungen effektiv steuern.

Bei EV -Bränden, die intensiver sein können als solche, an denen Fahrzeuge von Brennmotoren beteiligt sind, sind spezifische Brandbekämpfungsmethoden erforderlich. Löscher der Klasse D werden aufgrund ihrer Reaktivität mit Wasser für Lithium-Metall-Batteriebrände empfohlen.

Mit zunehmender EV -Zahlen wird die Notwendigkeit einer Entwicklung von Brandbekämpfungstechniken, z.

Effektive Richtlinien für den Umgang mit Li-Ionen-Batteriefeuer

- Im Falle einer fehlenden Li-Ionen-Batterie, die durch Zischen, Bräueln und Elektrolytleckage gekennzeichnet ist, ist die sofortige Wirkung von entscheidender Bedeutung, um potenzielle Gefahren zu vermeiden.

- Es wird empfohlen, ein Li-Ion-Feuer mit Wasser zu übergehen oder einen Standard-Feuerlöscher zu verwenden, um das Risiko einer Zündung in der Nähe brennbarer Materialien zu mildern.

- Beim Umgang mit Lithium-Metal-Bränden ist es aufgrund der reaktiven Natur von Lithium mit Wasser mit einem Feuerlöscher der Klasse D WEISSCHLUSS.

- In Ermangelung eines Löschers der Klasse D kann Wasser als Alternative verwendet werden, um zu verhindern, dass sich das Feuer effektiv ausbreitet.

- Für optimale Ergebnisse beim Löschen eines Li-Ionenfeuers können verschiedene Löschmittel wie Schaumstoff, CO2, ABC-Trockenchemikalie, Graphitpulver, Kupferpulver oder Soda verwendet werden, ähnlich wie bei serienmäßigen brennbaren Feuerszenarien.

- In Fällen, in denen eine brennende Lithium-Ionen-Batterie nicht gelöscht werden kann, ist es ein praktikabler Ansatz, dass das Rudel kontrolliert ausbrennen kann. Es ist wichtig, die Zellausbreitung zu überwachen, da jede Zelle in unterschiedlichen Raten brennen kann, wenn sie Wärme ausgesetzt sind, und scheinbar ausgebrannte Packungen sicher zu entsorgen, indem sie für einen bestimmten Zeitraum im Freien platziert werden, um potenzielle Risiken zu minimieren.