Points clés à retenir :

- La surcharge, les dommages physiques, les défauts de fabrication et les températures extrêmes sont les principales causes de fuites de batterie au lithium.

- Un stockage approprié, l'utilisation du chargeur droit, des inspections régulières et une manipulation minutieuse peuvent empêcher les fuites.

- Le confinement immédiat, l'élimination sûre et le nettoyage sont essentiels en cas de fuite.

Piles au lithium peut divulguer des liquides si leur composants internes devenir endommagé. Cependant, les batteries au lithium modernes ont plus de garanties et sont très peu susceptibles de fuir pendant une utilisation normale. Avec une manipulation appropriée, les fuites de batterie au lithium sont assez rares.

Qu'est-ce qui fait que les batteries au lithium fuisent?

Surcharge

L'une des causes les plus courantes de fuites de batterie au lithium est la surcharge. Lorsqu'une batterie lithium-ion est chargée au-delà de sa capacité de tension maximale, le liquide d'électrolyte à l'intérieur commence à se décomposer et à se décomposer. Cette réaction de décomposition d'électrolyte produit des sous-produits gazeux qui renforcent la pression dans le boîtier de batterie scellé.

En tant que supports de pression interne, les joints et les mécanismes de sécurité conçus pour contenir l'électrolyte peuvent commencer à échouer. Avec une accumulation de pression suffisante, le liquide électrolytique peut essentiellement se faire presser par n'importe quel point faible ou micro-fracture dans le boîtier de la batterie.

La surcharge génère également un excès de chaleur, ce qui accélère la dégradation de l'électrolyte en composés gazeux. Des tensions élevées combinées avec la chaleur multiplient rapidement les pressions internes.

Utiliser le mauvais chargeur ou laisser une batterie au lithium branchée et charger en continu bien au-delà de 100% sont des causes courantes de surcharge. Les chargeurs intelligents cesseront d'appliquer le courant lorsque la batterie est complètement chargée, mais les chargeurs muets continuent de couler des électrons. Cet afflux d'électrons sans aucun endroit pour qu'ils aillent est ce qui entraîne une décomposition des électrolytes et une fuite éventuelle.

Les piles au lithium avec des systèmes de gestion de batterie intelligente sont capables de surveiller tension dans les cellules individuelles et empêcher la surcharge. Cela rend une fuite complète de pack beaucoup moins susceptible qu'une batterie lâche unique surchargée. Pourtant, l'utilisation de batteries de nom de marque réputées et les chargeurs appropriés pour eux est important pour éviter de dépasser leur seuil de tension maximale.

Dommages physiques

Tout type de dommages physiques au boîtier extérieur d'une batterie de lithium peut entraîner des fuites. La chute, l'écrasement, la perforation ou la maltraitance mécanique d'une batterie entraîne souvent des dommages internes qui provoquent une fuite de liquide d'électrolyte.

Les batteries au lithium ont des séparations internes entre les électrodes positives et négatives. Ces séparateurs empêchent les électrodes de prendre contact et de court-circuiter la batterie. Cependant, des impacts physiques excessifs peuvent briser ces séparateurs et permettre à la cathode et aux feuilles d'anode de toucher.

Lorsque les électrodes se contactent directement, cela crée une chaleur intense au point de contact. Cette chaleur peut initier le runage thermique et accélérer les réactions chimiques exothermiques qui produisent des gaz. La batterie se balance rapidement de la pression de gaz. Dans le même temps, la fusion locale des électrodes produit des ouvertures pour que les gaz sous pression s'échappent avec un liquide électrolytique.

Même si la batterie n'est pas gravement écrasée, les petites perforations du boîtier des objets tranchants peuvent donner à l'électrolyte une voie d'évacuation directe. Une fois le boîtier compromis à partir de l'impact, des vibrations, de l'enflure ou des perforations, l'électrolyte a une voie pour s'infiltrer progressivement au fil du temps.

Les batteries au lithium doivent être manipulées avec soin pour éviter les gouttes, les collisions ou les piercings. Bien que le boîtier soit rigide, il ne peut pas résister à une force directe excessive. La prévention est cruciale, car les dommages physiques de la batterie entraînent presque toujours des fuites.

Défauts de fabrication

Bien que rares, la fabrication imparfaite peut entraîner des défauts microscopiques dans le boîtier de batterie ou des séparateurs internes qui provoquent des fuites au fil du temps. Les composants de la batterie passent par un contrôle de qualité rigoureux, mais un petit pourcentage d'unités défectueuses passera inévitablement.

De minuscules fuites de trou de sténopé dans le boîtier d'une batterie de lithium sont difficiles à détecter, mais peuvent permettre à un liquide d'électrolyte de s'infiltrer lentement pendant leur utilisation. Ces trous d'épingle peuvent se former à partir de couches de boîtier ou de contaminants à impréurs à imprégner dans le boîtier pendant la production. De même, des sceaux imparfaits autour des terminaux, des microfractures provenant de la contrainte et des couches d'isolement incomplètes peuvent survenir.

Contaminants introduits pendant le processus de fabrication peut également provoquer des défauts entre les électrodes. Les particules métalliques microscopiques errantes sont les plus problématiques, piquant potentiellement des trous dans les séparateurs internes. Dendrites ou “moustaches métalliques” Peut se développer progressivement sur des cycles d'utilisation et pénétrer la barrière de séparation.

Pendant les défaillances exotiques, certains contaminants ou réactions chimiques avec des électrodes peuvent produire un sous-produit corrosif. Cela peut lentement ronger le tubage ou le matériau du séparateur, élargissant les défauts jusqu'à ce que l'électrolyte fuit.

Les processus de contrôle de la qualité rigoureux visent à minimiser les défauts de fabrication grâce à des tests visuels et fonctionnels. Cependant, les défauts rares passeront et provoqueront des fuites ou une défaillance précoce seulement des semaines ou des mois dans la vie d'une batterie. Fabricants réputés Soutenu par les garanties est le meilleur pari pour minimiser les risques.

Températures extrêmes

Exposer les batteries au lithium à des températures très élevées ou très basses peut augmenter les chances de fuite. Le liquide d'électrolyte à l'intérieur de la batterie est conçu pour fonctionner à des températures ambiantes normales. Dépassant environ 140 ° F ou aller en dessous de 35 ° F pousse la solution d'électrolyte à l'extérieur de sa plage de fonctionnement stable.

À des températures très basses, la solution d'électrolyte peut geler et se développer, augmentant la pression à l'intérieur du boîtier. Cela peut entraîner l'échec des joints et des mécanismes de sécurité. Bien que rares, certains mélanges d'électrolyte qui gèlent en un changement de phase solide font l'expansion du volume, ce qui souligne également les parois de la batterie.

Les températures élevées sont encore plus problématiques. Lorsque les batteries dépassent 140 ° F, l'électrolyte commence à se décomposer thermiquement en composés gazeux. Cela accélère exponentiellement à mesure que les températures continuent d'augmenter. Les gaz chauds en expansion renforcent rapidement la pression jusqu'à ce que le boîtier se rompre.

Les batteries de lithium bon marché et de faible qualité sont les plus susceptibles de fuir et même de prendre feu lorsqu'elles sont exposées à des températures extrêmes à l'intérieur d'un véhicule chaud ou froid. Mais même les batteries de qualité présentent un certain risque si des conditions de congélation ou de surchauffe persistent.

Les batteries au lithium laissées dans les voitures pendant les vagues de chaleur estivales ou les congélations en profondeur hivernale courent le plus haut risque de défaillance liée à la température. Le stockage des batteries entre 40 ° F et 80 ° F minimisera tout risque de fuites induites par la température.

Comment savoir si votre batterie au lithium fuit

Fuite visible ou déformation

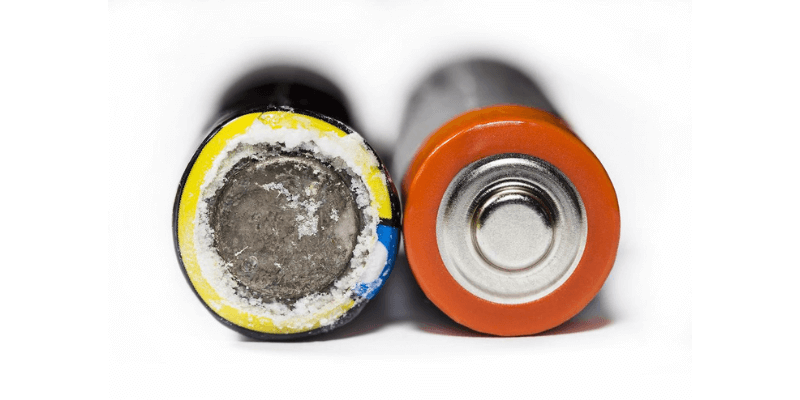

L'indicateur le plus évident qu'une batterie de lithium fuit est les taches visibles, la mise en commun du liquide ou les dépôts cristallisés autour de la batterie ou du compartiment de la batterie de l'appareil. Ceci s'accompagne souvent d'une odeur de vignoble piquante de la solution d'électrolyte qui s'échappe. Toute humidité, l'adhérence ou l'accumulation cristalline blanche autour d'une batterie de lithium indique presque certainement qu'elle a fait une fuite majeure.

De même, si une batterie de lithium est sensiblement ballonnée, gonflée ou déformée, cela signifie que les pressions gazeuses se sont construites en interne et ont compromis le boîtier. La déformation est causée par l'expansion du gaz à partir de la décomposition des électrolytes rompant les séparateurs internes. Une fois que la forme du boîtier de la batterie change, des violations plus importantes permettant une fuite de fluide visible suivent généralement peu de temps après.

Tests de détection de vide

Les appareils appelés détecteurs de fuite peuvent identifier des fuites de batterie très lentes avant que tout électrolyte visible ne s'est échappé. Ces dispositifs utilisent une pression sous vide et un capteur de gaz pour détecter les quantités infinitésimales de vapeur d'électrolyte émise par des brèches de boîtier microscopique.

La batterie suspectée est placée dans une chambre d'essai scellée qui est ensuite évacuée de l'air, créant un vide. Avec l'aspirateur contrôlé en place, tous les gaz qui fuyent même un minuscule trou d'épingle dans la batterie seront inspirés de la brèche. Le capteur de gaz du détecteur de fuite peut détecter des traces infimes de ces composés électrolytiques vaporisés.

Une batterie fonctionnellement fonctionnelle n'émettra pas de gaz lorsqu'il est soumis à un test de vide. Mais les défauts comme les trous d'épingle microscopiques, les joints fracturés ou les minuscules lacunes dans les joints de boîtier soudées à froid permettront de retirer les gaz contenus de la batterie. Le détecteur de fuite alarme lorsque son capteur ramasse tout ce qui est au-dessus des constituants d'air de base attendus.

La détection des fuites de vide permet donc d'identifier les batteries avec des échecs de joint à un stade précoce avant que suffisamment d'électrolyte ne fuit. Ils peuvent être remplacés de manière proactive avant que les fuites majeures et les dommages à l'appareil ne se produisent. Cependant, les tests sous vide nécessitent des équipements spécialisés qui ne sont pas facilement accessibles aux consommateurs.

Détection de substance des fuites

Des réactifs de liquide spécialisés et des bandes de test ont été développés pour détecter les défaillances du joint de batterie au lithium avant que les fuites ne soient visibles. Ces fluides de détection de fuite contiennent des composés qui réagissent avec l'électrolyte de batterie de lithium. Lorsque le liquide entre en contact avec des quantités encore minuscules de vapeur d'électrolyte ou d'humidité, il change de couleur.

Pour utiliser le fluide de détection de fuites, une batterie est retirée d'un appareil et le fluide appliqué autour des lignes de couture et des connexions de terminaux avec un écouvillon. Si le fluide change de couleur, il indique que les composés électrolytiques s'échappent par des brèches de boîtier microscopique.

Les bandes de test fonctionnent de manière similaire mais sont saturées du composé réactif par électrolyte plutôt que sous forme liquide. Les bandes sont simplement essuyées contre les coutures et les terminaux de la batterie, et tout changement de couleur signifie une fuite.

Cela permet de confirmer la défaillance du joint même lorsque les quantités qui fuisent sont insuffisantes pour voir. Il fournit une méthode pour identifier les batteries défectueuses avant les étapes de fuite visibles. Cependant, les fluides de détection de fuites et les bandes ne sont pas largement disponibles pour les consommateurs moyens. Ils nécessitent une distribution par le biais de fournisseurs de batteries ou d'électronique spécialisés.

Bien qu'il ne soit pas aussi sensible que les méthodes de vide, la détection externe des substances fournit un moyen accessible de vérifier les batteries pour les défaillances précoces avant que des fuites majeures ne se produisent et entraînent des dommages à l'appareil. Cela permet un remplacement proactif des unités défectueuses.

Que faire si votre batterie au lithium fuit

Mesures de premiers soins immédiats

Si vous découvrez une batterie de lithium qui fuit visiblement, prenez des précautions pour éviter un contact direct avec l'électrolyte et contenir des liquides renversés. La solution d'électrolyte peut être corrosive et irritante pour les yeux et la peau, alors portez des gants et de la protection des yeux lors de la manipulation d'une batterie qui fuit.

Utilisez des matériaux absorbants et isolants tels que le sable, la vermiculite ou la litière pour chat pour absorber tout électrolyte regroupé ou fluide. Des serviettes en papier ou des chiffons peuvent également être utilisés pour absorber les fuites, mais assurez-vous de les éliminer rapidement. Évitez d'utiliser un tissu ou des matériaux poreux qui maintiendront l'électrolyte contre les surfaces.

Contenir la batterie qui fuit dans un sac scellé robuste ou un récipient en plastique pour empêcher d'autres déversements ou vapeurs de s'échapper. Un sac de rangement à risque fuite conçu pour les déversements est idéal. Déplacez la batterie contenue à l'extérieur si possible, car la ventilation de la zone aidera à dissiper les fumées irritantes.

Appeler un équipe de nettoyage des matières dangereuses est recommandé pour des fuites à grande échelle où un électrolyte important s'est échappé. Ils ont les agents de neutralisation et les installations d'élimination appropriées pour résoudre la contamination lourde. Cependant, pour les fuites mineures, vous pouvez prendre des mesures simples pour minimiser les dangers avant l'élimination appropriée.

Nettoyage et précautions à long terme

Une fois qu'une batterie qui fuit est contenue en toute sécurité, nettoyez soigneusement toutes les surfaces qui entraient en contact avec l'électrolyte échappé. L'électrolyte de batterie au lithium peut laisser des résidus corrosifs à mesure que les éléments volatils s'évaporent.

Les produits chimiques de neutralisation conçus pour les déversements de batterie au lithium doivent être utilisés pour essuyer les surfaces affectées en fonction des instructions du produit. Le vinaigre domestique peut également aider à neutraliser les dépôts d'électrolyte alcalin. Cependant, le vinaigre ne doit pas établir de contact direct avec des matériaux de lithium car il peut déclencher une production de gaz inflammable.

Pour les appareils comme les téléphones ou les ordinateurs portables, démontez l'enceinte et nettoyez soigneusement tous les composants intérieurs que le liquide qui fuit peut avoir atteint. Les batteries doivent fournir une isolation électrique, mais si la fuite était extrême, l'utilisation d'alcool isopropylique et une brosse antistatique pour nettoyer les planches électroniques est recommandée. Permettre aux surfaces de sécher complètement avant de remonter les dispositifs après une fuite.

À l'avenir, inspectez l'électronique pour tous les signes de dommages qui auraient pu se produire de la fuite. Tous les composants défectueux affectés par l'exposition à l'électrolyte nécessiteront probablement le remplacement. Soyez également attentif à toutes les odeurs persistantes, aux sons de nouvelles fuites ou à des comportements anormaux de dispositifs qui peuvent indiquer des dégâts de fuite de batterie non résolus. Un appareil contaminé peut avoir besoin d'un entretien ou d'un remplacement professionnel si les problèmes persistent.

Quand remplacer la batterie

Toute batterie lithium-ion qui présente une fuite visible, un gonflement, une déformation ou des dommages nécessite un remplacement immédiat. Les batteries avec électrolyte s'échappant activement doivent être rapidement retirées des appareils et correctement jetées. Ces panneaux d'avertissement visibles signifient que la batterie a été compromise et probablement des circuits internes ou des défaillances de composants internes soutenues.

De même, les batteries au lithium qui échouent à l'aspirateur ou aux tests de fuite de substances doivent être remplacées. Même de minuscules fuites détectées à travers ces méthodes peuvent signaler des défauts susceptibles de s'aggraver en fuite majeure avec plus d'utilisation. Les défaillances précoces des défauts de fabrication garantissent également le remplacement de la batterie.

Pour les batteries multi-cellules, l'ensemble du pack peut avoir besoin de remplacement si une cellule individuelle était divulguée. L'électrolyte renversé peut potentiellement migrer entre les cellules dans un boîtier de batterie et causer des dommages à la corrosion non détectés. Les fuites compromettent également les connexions physiques-électriques entre les cellules d'un pack. Le remplacement de l'ensemble du pack évite les futurs problèmes.

Bien que toutes les batteries n'atteignent pas la fin de la durée de vie utile due aux fuites, toute batterie présentant une fuite, une déformation, des odeurs étranges ou des caractéristiques de performances anormales doit être retirée immédiatement du service. Ne prenez pas de risques sur les batteries en difficulté, ce qui entraîne des échecs dangereux.

Empêcher les fuites de batterie au lithium

Conditions de stockage appropriées

Le stockage correctement des batteries au lithium-ion est essentiel pour prévenir les fuites ou les dommages qui peuvent entraîner des échecs de sceau. Les conditions de stockage idéales maintiennent les batteries entre 40 et 80 ° F et évitent les températures extrêmes ou les larges fluctuations.

Les batteries doivent être conservées dans un emplacement sec avec une humidité minimale. L'humidité peut pénétrer le boîtier sur de longues périodes de stockage et provoquer une corrosion interne. Les sources directes de la lumière du soleil ou de la chaleur doivent également être évitées pour empêcher les batteries de surchauffe au-delà de leur plage de fonctionnement en toute sécurité.

Pour le stockage à long terme de la batterie dépassant un mois, les conteneurs isolés ou les boîtes de régulation de la température aident à maintenir la fenêtre idéale de 40 à 80 ° F. Des paquets de dessiccants en gel de silice peuvent également être ajoutés aux conteneurs de stockage pour contrôler l'humidité.

Les batteries se déversent légèrement au fil du temps pendant leur entrepôt. Les stocker à environ un état de charge de 40% est optimal pour prévenir les dommages causés par la décharge ou la surcharge à 100%. Les températures de réfrigérateur inférieures à 40 ° F ne sont pas recommandées pour les batteries au lithium-ion à long terme.

Garder les batteries dans des environnements passivement contrôlés par température et éviter l'humidité, le froid extrême ou la chaleur intense minimise le risque de défaillances du sceau et de fuite au fil du temps. Le stockage approprié est la première ligne de défense contre les fuites.

Évitez la surcharge

L'une des causes les plus évitables de fuite de batterie au lithium est la surcharge. Les batteries de charge devant leur cote de tension maximale renforcent la pression interne qui peut rompre les joints.

Il est crucial d'utiliser le chargeur approprié pour le type spécifique de batterie de lithium et de suivre les directives de charge. Les chargeurs de batteries Li-ion ont des circuits pour cesser de charger lorsqu'ils sont pleins. Les chargeurs génériques ou incompatibles peuvent surcharger. Ne laissez jamais de batteries en charge sans surveillance pendant de longues périodes.

Les batteries entièrement chargées doivent être rapidement retirées des chargeurs. Pour les appareils tels que les ordinateurs portables, évitez de les utiliser constamment tout en branchant des chargeurs une fois complètement chargés. La charge du filet peut encore surcharger progressivement la batterie au fil du temps.

Circuits de protection de la batterie et “intelligent” La technologie de charge s'est considérablement améliorée pour éviter la surcharge lorsqu'elle est utilisée correctement. Mais l'achat de qualité, les batteries de marque et les chargeurs certifiés reste important. Les marques réputées sont moins susceptibles d'avoir des défauts conduisant à des défaillances de fuite de surcharge.

Inspections régulières

L'inspection périodique des batteries au lithium peut aider à détecter les premiers signes de dommages ou de défauts qui peuvent entraîner des fuites sur la ligne. Donner des batteries une inspection visuelle et tactile rapide mensuelle est une bonne habitude.

Recherchez tout gonflement ou déformation notable dans le boîtier, car cela indique une accumulation de gaz dangereuse et une défaillance imminente. Vérifiez également la décoloration, les bosses, les fissures ou les perforations qui peuvent compromettre les joints. Essuyez la batterie et recherchez des signes de dépôts d'électrolyte cristalline.

Utilisez également votre nez. Donnez aux batteries un test de reniflement occasionnel et soyez vigilant pour toutes les odeurs âcres ou vignobles qui pourraient indiquer une brèche et une fuite. Toutes les odeurs décalées ou étranges détectées garantissent d'échanger une batterie suspecte.

Bien qu'il ne soit pas infaillible, les inspections régulières vous permettent d'attraper des problèmes à des premiers stades avant les échecs catastrophiques. La surveillance de l'état de la batterie vous donne la possibilité de remplacer les unités présentant des défauts bien avant le développement de fuites majeures. Quelques minutes par mois peuvent empêcher de plus gros problèmes.

Précautions pour la manipulation

Les batteries au lithium doivent être manipulées avec soin pour éviter les dommages physiques qui pourraient provoquer des fuites. Les batteries de chute, d'écrasement, de perforation ou de perçage peuvent briser les phoques et les boîtiers de protection.

Évitez de stocker des batteries de lithium en vrac où les objets métalliques peuvent contacter ou appuyer dans le boîtier. Les clés, les pièces, les outils et autres articles métalliques abrégés, les terminaux peuvent déclencher des échecs dangereux. Ne transportez jamais des batteries lâches dans des poches contenant du métal.

Lors de l'installation de batteries, assurez-vous que les alignements de polarité sont corrects. Tenter de forcer une batterie vers l'arrière dans un appareil peut endommager les bornes ou les circuits de protection. L'insertion de batteries dans la mauvaise orientation peut provoquer des shorts immédiats.

N'essayez pas de faire des batteries gonflées à partir de périphériques ou utilisez des outils pour éloigner les dépôts qui fuient avec force. Cela peut encore endommager la batterie et libérer plus d'électrolyte. L'enflure doit inciter à un démontage immédiat de dispositif pour accéder doucement et retirer les batteries.

Bien que conçu pour être robuste, les batteries lithium-ion nécessitent toujours une manipulation prudente pour éviter de compromettre leurs enveloppes durables. Une manipulation minutieuse minimise le risque de défauts physiques qui conduisent à des fuites dangereuses.

En utilisant le bon type de batterie

L'utilisation uniquement des batteries lithium-ion correctement spécifiques de marques réputées pour un appareil donné est importante pour éviter les fuites. Les batteries génériques ou les batteries incompatibles sont plus sujettes aux échecs et aux fuites de sceau.

Recherchez le type de batterie lithium-ion spécifique, la tension, la forme du connecteur, la capacité et les dimensions nécessaires pour un appareil. La correspondance des spécifications de la batterie de remplacement évite précisément les problèmes. Évitez les batteries génériques sans nom avec des notes vagues ou exagérées.

Tenez-vous en fonction des grandes marques de batteries grand public qui fournissent des spécifications techniques détaillées et des données de performance pour leurs batteries. Fabricants réputés comme Batterie Holographique ont un contrôle de la qualité et des tests de sécurité rigoureux qui minimisent les risques de fuites. Les batteries sont conçues spécifiquement pour les principaux fabricants d'appareils opposés à la responsabilité.

Bien que généralement moins cher, les batteries génériques de lithium peuvent couper les coins sur l'isolation, les évents de gaz, l'intégrité du boîtier ou d'autres facteurs de sécurité. Les batteries spéciales eBay revendiquant “grande capacité” sont les plus suspects. Sacrifier la sécurité pour les gains marginaux de capacité se retourne rapidement une fois qu'ils ont fuit. Investissez dans des batteries de qualité conçues pour la sécurité et la longévité.

FAQ sur les fuites de batterie au lithium

Quels sont les risques si ma batterie au lithium commence à fuir?

Les fuites de batterie au lithium présentent des risques de peau, d'irritation des yeux et respiratoires du liquide d'électrolyte et des fumées. Les dommages corrosifs aux composants de l'appareil et aux surfaces exposés à des fuites sont également un danger à considérer.

Comment puis-je identifier les signes de fuite dans ma batterie lithium-ion?

Des taches visibles, des dépôts croustillants, des odeurs âcres, une déformation / gonflement de la batterie ou du liquide à l'intérieur du compartiment de la batterie de l'appareil sont des signes clairs de fuite de batterie au lithium-ion.

Le liquide d'une batterie qui fuit est-il dangereux?

Oui, le liquide d'électrolyte à l'intérieur des batteries au lithium est corrosif et peut irriter les yeux, la peau et les muqueuses lors du contact. Un équipement de protection approprié doit être utilisé lors de la manipulation.

Quel niveau de toxicité les vapeurs d'une batterie de lithium fuit?

Les fumées de l'électrolyte de batterie de lithium qui fuit est considérée comme modérément toxique et peut provoquer une irritation respiratoire à des concentrations élevées, mais ventiler les zones pour éviter une exposition significative.

Les fumées sont-elles émises lorsque les batteries au lithium-ion divulguent-elles du tout dangereuses?

Les fumées des batteries de lithium-ion qui fuient peuvent être irritantes si elles sont inhalées, donc la ventilation est recommandée. Cependant, une toxicité grave est peu probable avec les expositions accessoires dans des conditions ventilées normales.

Conclusion

Bien que les fuites de batterie au lithium ne soient pas extrêmement courantes, être préparé avec des connaissances aide à éliminer le stress des incidents potentiels.

En comprenant ce qui provoque des fuites et en apprenant une manipulation, un stockage et une inspection appropriés, vous pouvez éviter de nombreux problèmes pour commencer.

Si une fuite se produit, les précautions de sécurité et les étapes de nettoyage peuvent la résoudre. Et l'identification de tout signe d'avertissement précoce permet un remplacement proactif des batteries défectueuses avant les échecs majeurs.