La scelta della batteria industriale giusta è vitale per l'efficienza quando si utilizzano i carrelli elevatori, sia per un camion che per una flotta. La batteria del carrello elevatore elettrico appropriato può risparmiare tempo e denaro a lungo termine.

In questo articolo, tratteremo varie batterie per carrelli elevatori, le loro differenze chiave e intervalli di prezzo.

TIPI DI BATTERE del carrello elevatore

Mentre propano, diesel e gas sono altre opzioni, i due terzi dei carrelli elevatori messi in servizio ogni anno sono elettrici.

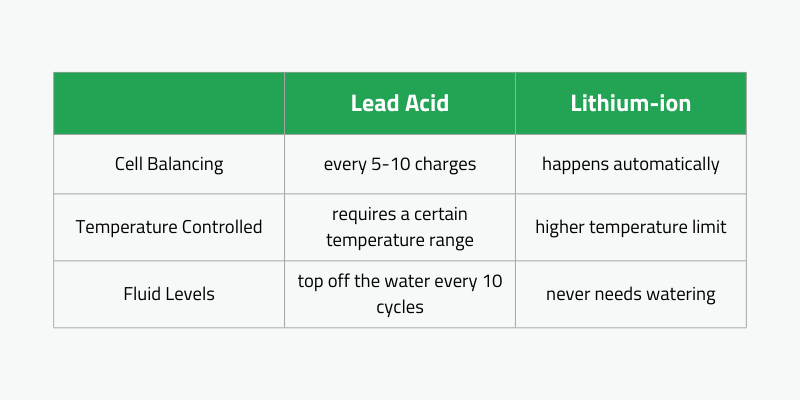

I carrelli elevatori elettrici sono alimentati principalmente da due tipi di batterie: ioni di piombo-acido e litio.

Il tipo di batteria influisce sulla frequenza di sostituzione: le batterie agli ioni di litio possono supportare oltre 3.000 cicli, mentre le batterie al piombo danno circa 1.500 cicli. Inoltre, le batterie agli ioni di litio richiedono una sostituzione meno frequente, rendendole preferibili a condurre batterie per molti proprietari di imprese.

Tensioni della batteria del carrello elevatore

I pacchetti di batterie del carrello elevatore vengono generalmente scelti in base alle apparecchiature di sollevamento e all'uso previsto. Esistono quattro opzioni di tensione comuni:

- 24V: Adatto per piccole apparecchiature di sollevamento elettrico come cavalieri finali, cavalieri centrali, stacker walkie e jack di Walkie Pallet.

- 36V: progettato per apparecchiature elettriche di medie dimensioni come carrelli elettorali stretti e carrelli elevatori controbilanciati in piedi.

- 48V: utilizzato per grandi apparecchiature elettriche, compresi i carrelli elevatori controbilanciati.

- 80V: riservato per apparecchiature elettriche per impieghi pesanti come grandi carrelli elevatori controbilanciati.

Carrello della batteria del carrello elevatore

Il modo in cui viene ricaricata la batteria di un camion di sollevamento elettrico influisce sull'efficienza operativa e le esigenze della stazione di ricarica.

Le batterie agli ioni di litio si caricano più velocemente e possono essere caricate opportunisticamente senza aver bisogno di una ricarica completa. Al contrario, le batterie al piombo-acido devono essere pienamente caricate prima di disconnettersi e non possono essere caricate opportunisticamente.

Entrambi i tipi si deteriorano se caricati in modo improprio, ma le unità di piombo-acido hanno linee guida più rigorose.

Requisiti di ricarica della batteria del carrello elevatore

La posizione del sistema di ricarica della batteria del carrello elevatore è fondamentale.

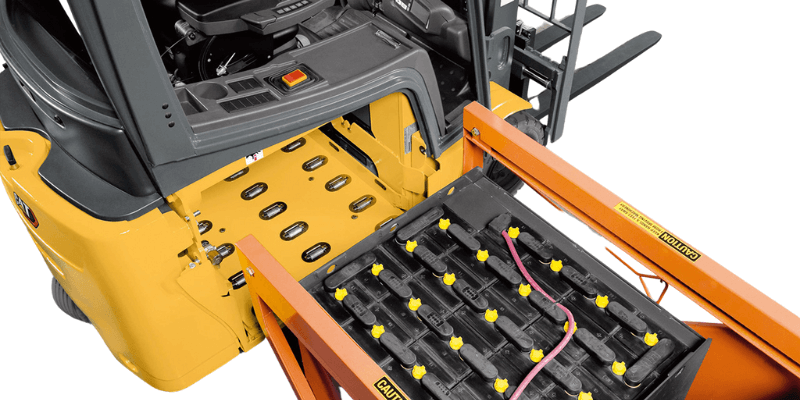

Le batterie al piombo-acido richiedono configurazioni specifiche che i pacchi agli ioni di litio non lo fanno. Le batterie agli ioni di litio possono caricare direttamente mentre sono ancora nel camion ascensore, senza ulteriori passi necessari.

Le batterie al piombo-acido devono essere rimosse per la ricarica su caricabatterie separati in grado di equalizzazione. Le aziende con molti carrelli elevatori necessitano di più caricabatterie e spazio affinché le unità si raffreddi dopo la ricarica. Questo processo richiede molto tempo, poiché i dipendenti hanno bisogno di attrezzature speciali per gestire regolarmente gli swap sulla batteria.

Inoltre, le aree di ricarica del piombo-acido richiedono una ventilazione adeguata a causa di fumi di calore e dannosi prodotti durante la ricarica. Al contrario, le batterie agli ioni di litio possono caricare direttamente nel camion ascensore senza bisogno di spazio dedicato o periodi di raffreddamento. Possono ricaricare immediatamente in loco quando scaricati.

Sistema di irrigazione della batteria del carrello elevatore

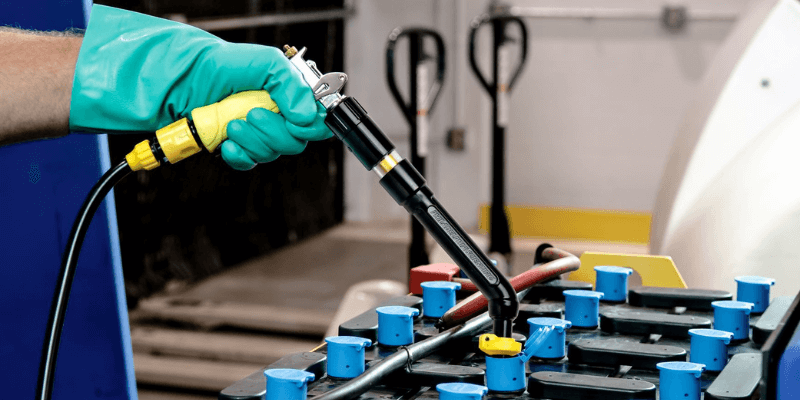

La ricarica non è l'unica manutenzione richiesta per le batterie al piombo; Il loro fluido ha bisogno di un'attenzione regolare.

A differenza delle batterie agli ioni di litio sigillate, le batterie al piombo richiedono un sistema di irrigazione. I dipendenti devono imparare ad annaffiare correttamente queste batterie per garantire prestazioni e longevità ottimali.

Le pratiche chiave per il mantenimento dell'irrigazione della batteria del carrello elevatore al piombo includono:

- Completare con acqua solo dopo essere completamente caricato e raffreddato.

- Riempire regolarmente per mantenere coperta la parte superiore delle piastre, di solito ogni 10 cicli di carica.

- Evitare il riempimento eccessivo per consentire l'espansione liquida durante l'uso.

- Usando acqua con un pH tra 5 e 7.

Sicurezza della batteria del carrello elevatore

La sicurezza è cruciale quando si maneggiano le batterie del carrello elevatore a causa delle potenti sostanze chimiche coinvolte. Confrontiamo le batterie agli ioni di litio e al piombo-acido in termini di sicurezza sul posto di lavoro.

I rischi per la sicurezza della batteria al piombo-acido sono i seguenti:

1. Sversamenti: l'acido solforico può riversarsi da queste batterie, soprattutto perché richiedono irrigazione settimanale. La gestione impropria aumenta il rischio dei dipendenti, che richiede una stazione di lavaggio chimica.

2. Surriscaldamento: queste batterie possono diventare estremamente calde durante la carica e possono perdere gas esplosivo dopo la carica di picco, rendendo il controllo della temperatura essenziale per la sicurezza.

3. Gas pericolosi: il sovraccarico può rilasciare gas tossici come idrogeno solforato, idrogeno e biossido di zolfo in aree scarsamente ventilate. Un odore di uovo marcio indica la presenza di idrogeno solforato; Le precauzioni immediate dovrebbero essere prese. Installare sensori di gas catalitico standard o sensori elettrochimici nelle stanze di ricarica per monitorare i livelli di gas.

4. Batterie vecchie o corrose: mentre le nuove batterie al piombo-acido comportano un rischio minimo se caricate correttamente, vecchie o corrose sono pericolose e devono essere eliminate immediatamente.

Al contrario, le batterie del carrello elevatore agli ioni di litio sono sigillate, eliminando i rischi di fuoriuscite di acido o corrosione.

Prezzi della batteria del carrello elevatore

I costi della batteria del carrello elevatore variano significativamente per tipo. Una batteria al piombo-acido varia da $ 2.000 a $ 6.000, mentre una batteria al litio costa tra $ 17.000 e $ 20.000.

Tuttavia, questi prezzi non riflettono il costo totale della proprietà (TCO). I manager dovrebbero considerare le spese a lungo termine associate a ciascun tipo prima di prendere una decisione.

Nelle operazioni di magazzino, il lavoro è il costo più grande, misurato in tempo. L'acquisto di batterie al piombo-acido aumenta i costi complessivi del carrello elevatore poiché richiedono ampie ore di uomo per il corretto funzionamento. Ogni batteria dura circa 8 ore e necessita di 16 ore per caricare e raffreddare, che richiede almeno tre batterie per carrello elevatore per le operazioni 24/7. Sono necessarie anche batterie extra per la manutenzione, portando a più documenti e una squadra dedicata per il monitoraggio.

Le batterie al piombo-acido sono grandi e richiedono spazio di archiviazione designato che soddisfa le linee guida canadesi per la salute e la sicurezza del lavoro, sostenendo costi aggiuntivi. E sono necessarie attrezzature specializzate per monitorare queste batterie.

Inoltre, esiste un rischio professionale a causa dei loro liquidi corrosivi; Le fuoriuscite possono fermare le operazioni e sostenere ulteriori costi di tempo.

Mentre i costi iniziali della batteria sono bassi, durano solo circa 1.500 cicli con una manutenzione adeguata, che richiede sostituzioni ogni 2-3 anni insieme ai costi di smaltimento per le vecchie unità.

Una batteria del carrello elevatore agli ioni di litio, d'altra parte, è più leggera del 55% rispetto alle batterie al piombo-acido e offre benefici come requisiti di spazio ridotti, ricarica più rapida, maggiore efficienza energetica, migliore sicurezza dei lavoratori, migliori prestazioni a freddo e maggiore produttività.

Conclusione

Le batterie agli ioni di litio, sebbene inizialmente più costose, forniscono risparmi a lungo termine attraverso l'efficienza e la minore manutenzione. La loro rapida ricarica, durata e sicurezza li rendono ideali per i carrelli elevatori.

Quando si sceglie tra acido di piombo e ioni di litio, considerare le tue esigenze di frequenza di utilizzo e sicurezza. Un investimento di batteria intelligente aumenta la produttività e riduce i tempi di inattività, aiutando la tua azienda a rimanere competitiva nel mercato del carrello elevatore elettrico.