Executive Summary for Engineers:

- The Competitor: Premium “Low-Temp” LFP cells (like the PLB 26650) are excellent, offering 75% discharge at -20°C.

- The Problem: To charge below -20°C, LFP requires active heating. This adds cost, failure points, and parasitic energy loss.

- The Solution: Sodium-ion battery packs deliver 88% native retention at -20°C and can sit at 0V indefinitely.

- Verdict: Use Low-Temp LFP for energy density. Use sodium-ion for simplified, maintenance-free cold weather reliability.

For the past five years, “저온 LFP” 극한의 추위에도 믿을 수 있는 유일한 배터리 옵션이었습니다. – like GPS trackers in Minnesota or solar stations in Harbin.

These batteries, such as the PLB IFR26650-34D, can discharge at -40°C, but charging and storage remain challenging.

Keeping LFP 배터리 alive in winter requires PI heating films, insulation cotton, and complex BMS programming to pre-warm before charging. This heated setup works but is complicated and introduces extra loads and failure points.

At Holo Battery, we asked: What if the battery didn’t need all that? That’s why we’re now focusing on 나트륨 이온 for cold-weather use. Here’s the engineering breakdown.

Native Capacity vs. Parasitic Heating

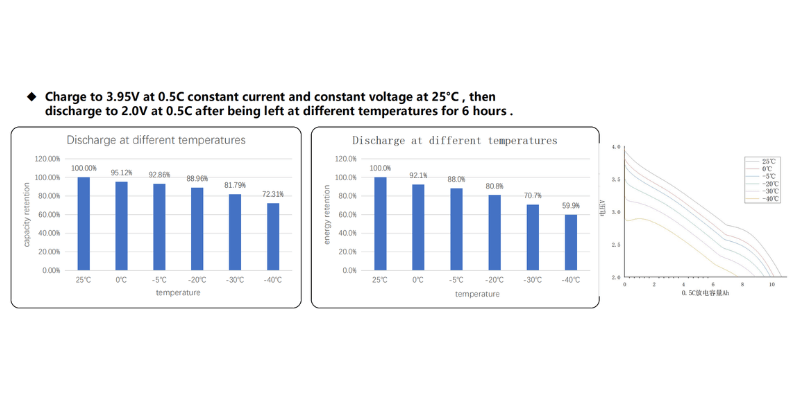

When we look at the raw data from our lab tests at -20°C, the difference between “Native Performance” 그리고 “Managed Performance” becomes clear:

| 특징 | Premium Low-Temp LFP | Sodium-ion |

| -20°C Discharge | 75% (at 1C) | 88.9% (at 0.5C) |

| Voltage Sag | Significant (avg 2.8V) | Moderate (avg 2.9V) |

| Heating Req. | Mandatory for Charging | 없음 |

The Mathematics of “The Heating Tax”

To make LFP work reliably at -30°C, you cannot use the bare cell. You must use a heating element. This introduces a “Heating Tax” – energy that is burned just to facilitate the battery’s operation, rather than powering your device.

Let’s do the math on a typical solar scenario:

- Thermal Mass: A 12V 100Ah LFP battery pack weighs approx. 9-12kg.

- Specific Heat: Raising that mass from -30°C to 0°C (the safe charging temp) requires significant energy.

- The Loss: In a real-world system, you often lose 10-15% of your total solar yield just to power the heating film.

Sodium-ion Approach: We stripped the heaters. The sodium-ion chemistry is natively conductive at low temps due to the smaller stokes radius of sodium ions in the 전해질. Around 90% capacity is available instantly, with zero warm-up time and zero parasitic loss.

The Charging Wall: -20°C Limit

The most dangerous line in any LFP datasheet is usually buried in the fine print. For the PLB 26650, it reads: “Standard charging current: 0.2C at -20°C.”

Why Lithium Plates (and Sodium Doesn’t)

Below -20°C, the intercalation of lithium ions into the graphite anode becomes sluggish. If you force current into the battery (Charging), the ions pile up on the surface of the anode instead of going inside. This forms Metallic Lithium Plating.

- The Risk: These dendrites can pierce the separator, causing an internal short circuit and 열 폭주.

This is why LFP must heat itself above freezing before accepting high currents.

In a solar street light application, winter daylight is short (4-6 hours). If your LFP battery spends the first hour heating itself up, you have wasted 20% of your precious charging window.

Sodium-ion Advantage: Sodium ions have superior solvation kinetics. They don’t “plate” as easily as lithium. While charging slows down in extreme cold, it remains safe. We have validated safe charging at -20°C without external heat, simplifying the BMS architecture significantly.

The Supply Chain Killer: 0V Storage

This feature is often overlooked by engineers but is the number one request from Supply Chain Managers.

The Chemistry of “Death by Zero Volts”

Why does an LFP battery die if it hits 0V?

It comes down to the current collectors. The anode uses Copper Foil. When voltage drops below 1.5V, the copper begins to oxidize and dissolve into the electrolyte. When you try to recharge it, that dissolved copper precipitates as sharp dendrites, causing a short circuit. The battery is effectively scrap metal.

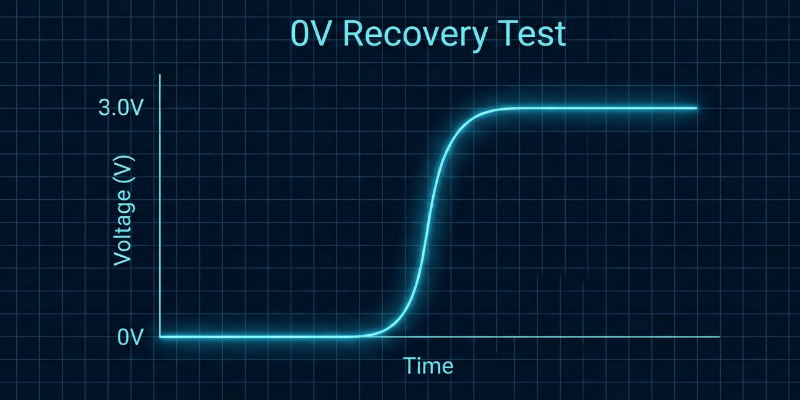

The Sodium Miracle:

Sodium-ion batteries use Aluminum Foil for both the cathode and the anode (because sodium doesn’t alloy with aluminum). Aluminum is chemically stable at 0V.

We tested the NaCR32140 cell by intentionally draining it to 0V, shorting the terminals, and leaving it for 24 hours.

Result: Upon reconnection, it charged back to full capacity with no side effects.

What this means for your logistics:

Air Freight Safety: We can ship sodium-ion packs completely discharged (0V), bypassing many dangerous goods regulations.

Inventory Resilience: You can leave equipment in a warehouse for 2 years. When you pull it out, it works. No “maintenance charging” schedules required.

The Verdict: Engineering the Right Choice

We are not saying LFP is dead. If you need maximum runtime in a heated warehouse, LFP is still king (high energy density).

But for the edge of the grid, simplicity is reliability.

Choose Sodium-ion if:

- Temperature: Your device faces -20°C to -40°C.

- Power Source: Intermittent charging (Solar/Wind) where you can’t waste power on heaters.

- Reliability: You want to eliminate the failure points of heating films, thermostats, and BMS relays.

- Storage: You have long supply chains or seasonal inventory.

Stop fighting the cold with heaters. Embrace chemistry that likes the cold.