Key Takeaways:

- Prismatic vs. Cylindrical Cells: Prismatic cells offer higher volumetric energy density and are suitable for large battery packs, while cylindrical cells provide higher gravimetric energy density and lower manufacturing costs.

- Ideal Use Cases: Prismatic cells excel in electric vehicle battery packs and large energy storage systems, while cylindrical cells are preferred for consumer electronics and power tools.

- Trends and Outlook: The shift towards prismatic cells for EVs and energy storage systems is evident, but cylindrical cells remain dominant in cost-sensitive applications.

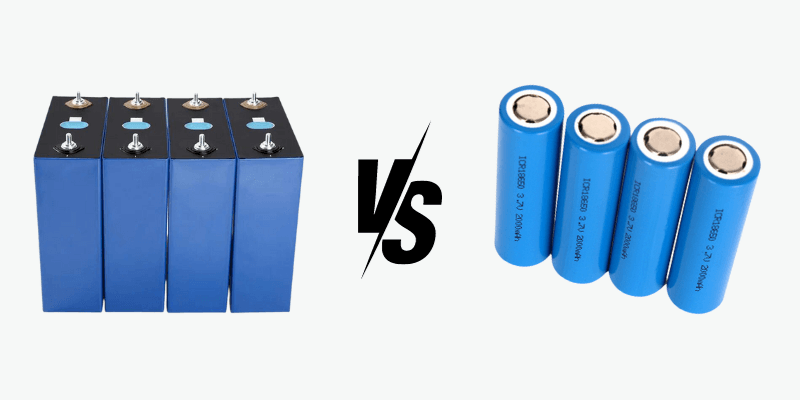

Prismatic and cylindrical are the two most common lithium-ion battery cell shapes used today. While both have distinct advantages and disadvantages for different applications, prismatic cells are gaining popularity for their efficient packing capability and suitability for large battery packs. This article compares prismatic vs cylindrical cells in depth, analyzing the key differences in size, performance, cost, and ideal use cases.

What Are Prismatic Battery Cells?

Definition and description of prismatic cells

Prismatic battery cells, as the name suggests, are prismatic in shape – they have a rectangular, box-like form factor. The term “prismatic” refers to a geometric prism shape.

Prismatic cells maximize the flat surface areas of the anode, cathode, and separator layers, allowing them to be stacked efficiently.

How prismatic cells are constructed

Prismatic cells are constructed by stacking alternating layers of cathode, anode, and separator material, then encasing them in a rectangular aluminum or steel can. The electrode layers are connected via tabs, allowing current to flow.

It also contain electrolyte for ion transport. The hard casing helps maintain the cell’s shape and provides structural integrity.

Common prismatic cell sizes and chemistries

Common prismatic lithium-ion battery sizes include the 103450 (103mm x 45mm), 14650 (146mm x 50mm), and larger formats like the 22700 and 32113. Unlike the cylindrical 18650 cell, these sizes are specifically for prismatic geometries.

Prismatic cells are often bundled together in modules and packed efficiently to form large battery packs for electric vehicles, energy storage systems, and other applications requiring high capacity.

Lithium iron phosphate (LiFePO4) and nickel manganese cobalt oxide (NMC) are two popular cathode chemistries used in prismatic cells. The prismatic format allows flexibility in the cathode formulation and cell dimensions to optimize performance.

What Are Cylindrical Battery Cells?

Definition and description of cylindrical cells

Cylindrical battery cells, as the name implies, have a long cylinder shape resembling a tube or can. The positive and negative electrode sheets are rolled or wound up into a “jelly roll” and placed inside a cylindrical metal can, typically made of steel or aluminum. This creates an alternating spiral stack of cathode, anode, and separator material within the cell.

The cylindrical design maximizes the area of the electrode sheets that can fit within the confined space. The radial symmetry also helps evenly distribute stress and internal forces. Cylindrical cells come in various diameters and heights to accommodate different capacities.

How cylindrical cells are constructed

Cylindrical cell manufacturing starts with coating the cathode and anode sheets on thin metal foils, usually copper for anode and aluminum for cathode. These coated sheets are then tightly wound with a separator membrane to create the jelly roll electrode assembly. Occasionally, the electrode sheets are stacked and folded rather than wound.

The jelly roll is inserted into the cylindrical steel or aluminum can, which serves as the external case. A cap and gasket seal the can. Finally, electrolyte is injected into the cell to enable ion flow between the anode and cathode. The cylindrical can provides structure and protects the electrodes.

Automated winding machines ensure consistent tightness and alignment of the jelly rolls during high-volume production. Precise winding is critical to minimize electrical resistance and maximize performance.

Common cylindrical cell sizes and chemistries

Some of the most widely used cylindrical lithium-ion battery sizes are 18650, 26650, 21700, and 20700 cells. The 18650 size is commonly used in laptop batteries, power tools, and other consumer devices. Larger formats like 21700 and 26650 are growing in popularity for e-bikes, scooters, and EVs.

Cylindrical cells have traditionally utilized lithium cobalt oxide (LiCoO2) and lithium manganese oxide (LiMn2O4) as cathode materials. Now, nickel-rich chemistries like nickel cobalt aluminum oxide (NCA) and nickel manganese cobalt oxide (NMC) are also common in high-performance cylindrical cells.

Key Differences Between Prismatic and Cylindrical Cells

Size and Shape

- Prismatic cells are typically larger in size. Common prismatic sizes range from 103450 (103 x 45 mm) up to 530450 (530 x 450 mm) or larger.

- Common cylindrical cell sizes include 18650 (18 x 65 mm), 26650 (26 x 65 mm), and 21700 (21 x 70 mm). Cylindrical cells max out around 46 x 150 mm.

- Prismatic cells have volumetric energy density around 600-700 Wh/L compared to 500-600 Wh/L for cylindrical cells.

Power and Energy Density

- Cylindrical cells achieve higher gravimetric energy density of 260 Wh/kg compared to around 200 Wh/kg for prismatic cells.

- Power density for quality cylindrical cells reaches up to 1500 W/kg versus 1000-1200 W/kg for prismatic.

Manufacturing and Costs

- Cylindrical cell winding machines can produce over 300,000 cells per day with lower labor costs.

- Large-scale prismatic cell fabrication has more complex stacking, pressing, and welding steps. Output is around 50,000 cells per day.

- As a result, cylindrical cells currently have a 15-20% lower cost per kWh compared to prismatic cells.

Performance and Lifespan

- Prismatic cells often last over 5,000 charge/discharge cycles before degrading 20%.

- Cylindrical cells typically achieve 2,000-3,000 cycles before 20% degradation due to higher swelling.

- Prismatic cells have 5-10% higher resistance which slightly lowers power capability.

Here is the section on when to use prismatic vs cylindrical cells:

When to Use Prismatic vs. Cylindrical Cells

Applications Better Suited for Prismatic Cells

- Electric vehicle battery packs

- Large energy storage systems

- Applications requiring high energy density

Prismatic cells are well-suited for these applications because their shape and construction allows for efficient high-capacity battery packs. The rectangular prism shape stacks and packs better than cylindrical cells.

Prismatic cells also have advantages like better thermal management capability and structural rigidity to prevent swelling.

Applications Better Suited for Cylindrical Cells

- Consumer electronics

- Power tools

- Applications requiring lower cost cells

Cylindrical cells work well for these applications because they are inexpensive to manufacture at high volumes. The cylindrical shape also provides good power density and fast charging ability, which is important for devices like power tools. Their smaller form factor fits well in handheld electronics.

Recent Trends and Future Outlook

- Shift towards prismatic cells for electric vehicle battery packs and large energy storage systems. Manufacturers are increasingly adopting prismatic cells for the packaging and performance advantages.

- Cylindrical cells still preferred for many consumer electronics and tools due to their lower cost. But some premium devices are shifting to prismatic cells as well.

- If manufacturing costs of prismatic cells continue to decrease, they could take more market share across all applications in the future. But cylindrical cells will likely maintain dominance in cost-sensitive applications.

The Pros and Cons of Prismatic vs. Cylindrical Battery Cells

| Prismatic | Cylindrical | |

| Pros | High volumetric energy density Long cycle life | High gravimetric energy density High power density Low manufacturing costs |

| Cons | Slightly lower power density Higher $/kWh cost | Lower volumetric energy density Shorter cycle life |

When selecting between prismatic and cylindrical lithium-ion cells, there are tradeoffs to consider based on the application requirements. Prismatic cells provide excellent energy density thanks to their shape and rigid casing, making them ideal for battery packs that need to maximize capacity. However, cylindrical cells deliver higher peak power and lower cost, at the expense of pack-level density and swelling issues.

For low-power consumer devices where cost is critical, cylindrical cells remain the dominant choice. But applications demanding the highest energy densities like EVs are shifting to prismatic formats despite their higher cost. With continuing improvements in manufacturing and densities, prismatic cells will likely gain broader appeal across more applications in the future. But ease of production means cylindrical cells are here to stay as well, especially for cost-sensitive uses.

By carefully weighing these pros and cons, battery engineers can select the optimal cell type to meet their performance, lifespan and cost requirements.

Related Articles: