Recomandări cheie:

- Echilibrarea celulelor LiFePO4 este esențială pentru menținerea performanței și siguranței de vârf.

- Explorați tehnici, diferențe față de bateriile SLA și aplicații din lumea reală care revoluționează soluțiile de stocare a energiei.

Înainte construirea acumulatorului, este important să vă asigurați că toate celulele LiFePO4 sunt potrivite în ceea ce privește capacitatea nominală, tensiunea și rezistența internă. Mai mult, echilibrarea celulelor post-fabricare este o necesitate.

Acest articol vă va servi drept ghid pentru înțelegerea echilibrării celulelor LiFePO4.

Să ne scufundăm direct!

Înțelegerea echilibrului celular: ce este?

Echilibrarea celulelor este un concept care provine din practica de reglare a celulelor în funcție de capacitatea și tensiunea lor. Acest proces asigură că tensiunile sunt controlate în timpul ciclării bateriei pentru a menține echilibrul sau pentru a obține tensiuni aproape egale la toate nivelurile de stare de încărcare (SOC).

Este important să înțelegeți că echilibrarea celulelor nu este o procedură unică, ci mai degrabă o necesitate continuă atât înaintea și după asamblarea bateriei, cât și pe parcursul ciclului de viață al bateriei, pentru a menține performanța de vârf.

Acest principiu este similar cu metoda folosită atunci când se încearcă armonia între bateriile individuale configurat în serie.

Echilibrarea diferențelor dintre celulele LiFePO4 și SLA

Procesul de echilibrare a celulelor LiFePO4 implică utilizarea unei plăci de circuite, care ar putea fi un circuit de echilibrare, un modul de circuit de protecție (PCM) sau sistem de management al bateriei (BMS). Aceste componente sunt responsabile pentru monitorizarea bateriei și a celulelor acesteia.

Când o baterie se apropie de 100% starea de încărcare (SOC), un circuit de echilibrare egalizează tensiunile fiecărei celule din baterie folosind hardware. Tensiunea standard a celulei pentru fosfatul de litiu fier pentru a echilibra mai sus este de 3,6 volți.

În schimb, PCM sau BMS nu numai că mențin echilibrul prin hardware, dar oferă și protecție suplimentară și capacități de gestionare în circuitele lor, care protejează bateria dincolo de ceea ce poate face un simplu circuit de echilibrare. Aceasta include limitarea curentului de încărcare/descărcare al bateriei.

Bateriile cu acid plumb sigilat (SLA) sunt gestionate diferit de bateriile cu litiu și, prin urmare, procesul lor de echilibrare este și el distinct. O baterie SLA atinge echilibrul fiind încărcată la niveluri de tensiune puțin mai mari decât normale, deoarece nu dispun de sisteme de monitorizare interne.

Pentru a preveni evadarea termică, aceste baterii necesită monitorizare externă fie prin dispozitive precum hidrometre, fie manual de către o persoană, ca parte a procedurilor de întreținere de rutină; acesta nu este un proces automat.

Tehnici și tehnologii utilizate pentru echilibrarea eficientă a celulelor LiFePO4

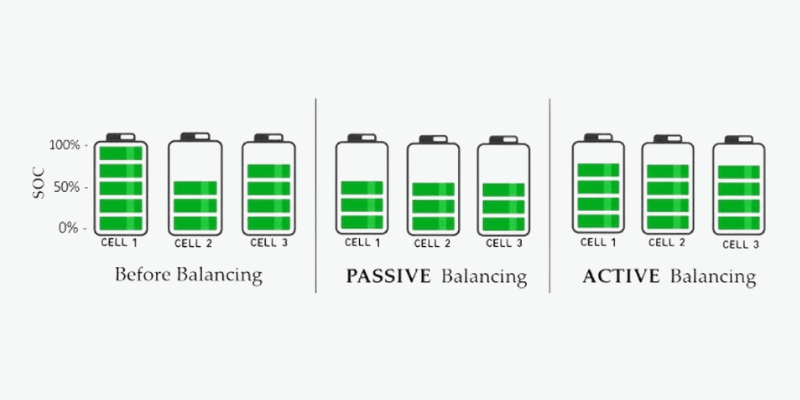

Există două tehnici principale folosite pentru echilibrarea celulelor LiFePO4: echilibrarea activă și pasivă.

Echilibrarea pasivă implică disiparea încărcăturii în exces de la celulele de tensiune mai mare către celulele de tensiune mai joasă prin rezistențe sau circuite de șunt.

Deși această metodă este simplă și rentabilă, este posibil să nu fie la fel de eficientă ca echilibrarea activă în asigurarea nivelurilor uniforme de încărcare în toate celulele.

Echilibrarea activă, pe de altă parte, utilizează circuite electronice pentru a redistribui în mod activ energia între celule. Această tehnică este mai precisă și poate ajuta la menținerea tensiunilor constante ale celulelor, ceea ce duce la îmbunătățirea sănătății generale a bateriei.

BMS avansat joacă un rol cheie în implementarea eficientă a acestor tehnici de echilibrare. BMS poate monitoriza tensiunile, temperaturile și curenții individuale ale celulei pentru a asigura performanțe optime, protejând în același timp bateria de supraîncărcare sau supradescărcare.

Motivele convingătoare din spatele echilibrării celulelor LiFePO4

Dacă celulele LiFePO4 nu sunt echilibrate, poate duce la probleme precum capacitatea redusă, durata de viață scurtă și chiar pericole de siguranță, cum ar fi supraîncălzirea sau incendiile.

Echilibrarea celulelor LiFePO4 asigură că fiecare celulă din pachetul de baterii este încărcată și descărcată uniform. Acest lucru ajută la optimizarea performanței generale a sistemului de baterii și previne supraîncărcarea sau descărcarea excesivă a oricărei celule.

Prin echilibrarea celulelor LiFePO4, maximizați, în esență, eficiența și fiabilitatea acumulatorului. Acest proces ajută la prelungirea duratei de viață a bateriilor, la îmbunătățirea capacităților lor de stocare a energiei și la promovarea funcționării în siguranță.

Aplicații din lumea reală: cum echilibrarea celulelor LiFePO4 revoluționează soluțiile de stocare a energiei

De la sisteme de stocare a energiei solare până la vehicule electrice (EV) și bănci de alimentare portabile, utilizarea celulelor echilibrate cu fosfat de fier și litiu revoluționează modul în care stocăm și utilizăm energia.

În sistemele de stocare a energiei solare, echilibrarea celulelor LiFePO4 asigură performanța optimă și longevitatea bateriilor. Menținând fiecare celulă într-o stare de încărcare constantă, aceste sisteme pot stoca în mod eficient excesul de energie solară pentru utilizare în perioadele de lumină solară scăzută sau cerere mare.

Vehiculele electrice beneficiază și ele foarte mult de pe urma acestei tehnologii. Celulele LiFePO4 cu echilibrare adecvată ajută la îmbunătățirea performanței generale și a gamei de vehicule electrice, asigurând în același timp siguranța prin prevenirea problemelor de supraîncărcare sau supraîncălzire.

Bateriile de alimentare portabile echipate cu celule echilibrate de fosfat de fier de litiu oferă utilizatorilor o sursă de încredere și sigură de energie de rezervă în mișcare. Echilibrarea precisă a celulelor din aceste bănci de alimentare maximizează eficiența și prelungește durata de viață a acestora, oferind utilizatorilor o soluție energetică durabilă și de lungă durată.

Prin încorporarea echilibrării celulelor LiFePO4 în soluțiile de stocare a energiei, industriile sunt capabile să obțină performanțe îmbunătățite, caracteristici de siguranță îmbunătățite și fiabilitate sporită în produsele lor. Această tehnologie deschide calea pentru un viitor mai durabil și mai eficient în aplicațiile de stocare a energiei.

Concluzie

În concluzie, integrarea tehnologiei de echilibrare a celulelor LiFePO4 este un pas semnificativ către obținerea de soluții energetice durabile și prelungirea duratei de viață a bateriilor.

Prin asigurarea performanței și eficienței optime a bateriilor litiu-ion, echilibrarea celulelor nu numai că sporește fiabilitatea sistemelor de stocare a energiei, dar contribuie și la reducerea impactului asupra mediului.

Articole înrudite: