Poltrdne baterije, inovativna baterijska tehnologija, ponujajo prednosti pred litijeve baterije. Ta članek jih opredeljuje, primerja z litijevimi baterijami, razpravlja o njihovih prednostih in izzivih.

Kaj je poltrdna baterija?

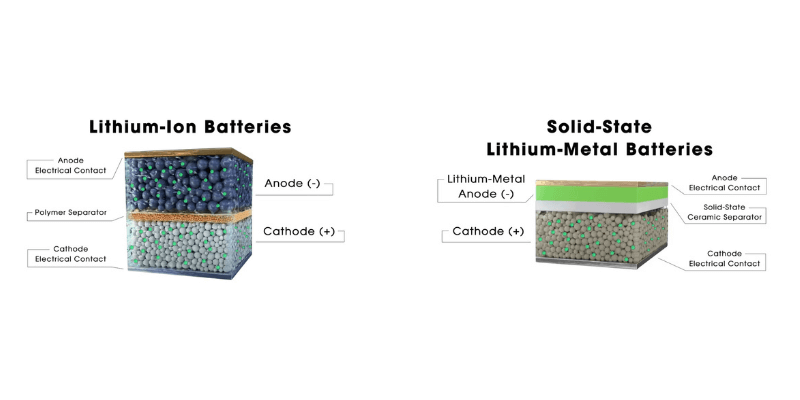

Poltrdne baterije so baterije za polnjenje, ki uporabljajo poltrdne baterije elektrolit. Ta elektrolit je običajno sestavljen iz trdnega prevodnega materiala, suspendiranega v tekočini, ki ponuja številne prednosti pred običajnimi oblikami.

Poltrdna baterija v primerjavi s tekočimi litijevimi baterijami

Glavne razlike med tema tehnologijama so v sestavi elektrolitov, varnosti in učinkovitosti:

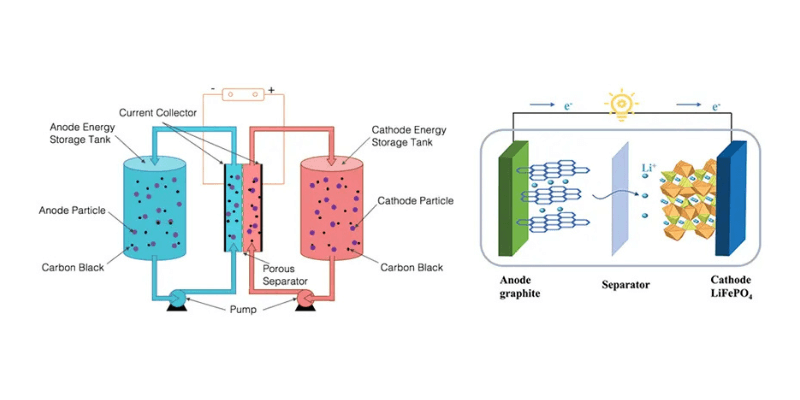

Struktura elektrolita

- Tekoče litijeve baterije: uporabljajte vnetljive organske tekoče elektrolite, ki predstavljajo nevarnost puščanja in toplotni beg.

- Poltrdne baterije: uporabite viskozni elektrolit v obliki gela/paste, ki zmanjšuje vnetljivost in omogoča tanjše ločevalnike.

Varnost

- Tekoči elektroliti se lahko vnamejo pod stresom (npr. zaradi fizične poškodbe ali prekomernega polnjenja), kar povzroči požar.

- Poltrdni elektroliti so odporni proti rasti dendritov, prenašajo temperature nad 200 °C in zmanjšajo tveganje vžiga pri testih penetracije žebljev.

Uspešnost

- Gostota energije: Tekoče litijeve baterije največ pri 300 Wh/kg; poltrdne različice dosežejo 350–400 Wh/kg.

- Življenjska doba cikla: tekoče litijeve baterije zdržijo približno 1200 ciklov; poltrdni zdržijo 2.000–3.000 ciklov z več kot 85-odstotno ohranitvijo zmogljivosti.

- Temperaturno območje: tekoči elektroliti zmrznejo pod 0 °C ali se zgostijo v hladnih razmerah. Poltrdne baterije delujejo od -40°C do 60°C brez znatne izgube učinkovitosti.

Proizvodnja

Tekoče litijeve baterije imajo koristi od uveljavljenih proizvodnih linij, medtem ko poltrdne zahtevajo spremenjene procese.

Prednosti poltrdnih baterij

Poltrdne baterije imajo več prednosti pred tradicionalnimi tekočimi litijevimi baterijami.

Izboljšana varnost

Zmanjšanje vsebnosti tekočine in uporaba trdnih ogrodij zmanjšujeta nastajanje dendritov in toplotni odtok. Keramično izboljšani elektroliti, kot so sulfidni ali polimerni kompoziti, preprečujejo kratke stike. Poltrdne celice prestanejo teste penetracije z žeblji z minimalnim tveganjem vžiga, s čimer odpravljajo ključno napako pri tekočih litijevih baterijah.

Višja gostota energije

Poltrdne baterije dosežejo 30–40 % višje energijska gostota kot tekoče litijeve baterije z uporabo visokozmogljivih anod, kot sta litij ali silicij, v kombinaciji z visokonapetostnimi katodami NMC/NCA, bogatimi z nikljem.

Podaljšana življenjska doba & Odpornost

Zmanjšana degradacija elektrod in stabilni vmesniki omogočajo več kot 2000 ciklov z minimalno izgubo zmogljivosti. Dobro se obnesejo tudi pri ekstremnem mrazu (–40 °C), saj preprečujejo zmrzovanje elektrolitov.

Razširljivost

Poltrdne različice uporabljajo obstoječo litij-ionsko proizvodno opremo, kar zmanjšuje stroške prehoda v primerjavi s popolnoma polprevodniškimi baterijami. Podjetja, kot sta BMW in Ford, pospešujejo proizvodnjo s partnerstvom s Solid Power.

Zakaj imajo poltrdne baterije visoko energijsko gostoto?

Tri inovacije povečujejo Shranjevanje energije poltrdnih baterij:

Materialne inovacije

- Anode: kovinski litij (3.860 mAh/g) ali silicijevi kompoziti nadomeščajo grafit (372 mAh/g).

- Katode: NMC z visoko vsebnostjo niklja ali oksidi, bogati z litijem, povečajo napetost in kapaciteto.

Optimizacija elektrolitov

- Dvofazni dizajni (npr. polimerni geli s keramičnimi polnili) zmanjšajo število inertnih komponent, kar poveča prostor za aktivne materiale.

- Strjevanje na kraju samem izboljša stik med elektrodo in elektrolitom ter zmanjša notranji upor.

Strukturna učinkovitost

Elektrode imajo porozne matrice za zadrževanje več aktivnega materiala, medtem ko krajše ionske poti v kompaktnih oblikah povečujejo gostoto moči.

Izzivi poltrdnih baterij

Čeprav so poltrdne baterije obetavne, se soočajo z nekaterimi izzivi, ki jih je treba premagati.

Zapletenost materiala in dobavne verige

- Trdni elektroliti visoke čistosti, kot so sulfidi in oksidi, zahtevajo stopnjo čistosti nad 99,99 % in specializirano ravnanje zaradi občutljivosti na vlago, razgradnjo nad 20 ppm. To zahteva skladiščenje z argonom, kar povečuje stroške in logistično zapletenost.

- Ti materiali potrebujejo 40 % več PTFE veziv kot običajni PVDF, kar obremenjuje dobavne verige kemikalij.

Ozka grla v proizvodnji

- Kalandriranje elektrod mora vzdrževati 15–20 % višje gostote, pri čemer se časi sušenja skrajšajo z 12–24 ur na 2–3 ure, zaradi česar so potrebne naknadno opremljene proizvodne linije.

- Medfazni upor zaradi stika trdna-trdna elektroda-elektrolit lahko poveča notranji upor do 300 %, kar zmanjša učinkovitost in zmogljivost hitrega polnjenja.

- Tehnike strjevanja na kraju samem se trudijo doseči enotne vmesnike med elektrodo in elektrolitom, kar vpliva na življenjsko dobo cikla in stabilnost delovanja.

Omejitve delovanja

- Hibridni elektroliti kažejo 10–30 % nižjo ionsko prevodnost kot tekoči pri temperaturah pod ničlo, kar omejuje izhodno moč v hladnih podnebjih.

- Tveganja litijevega dendrita obstajajo tudi po več kot 500 ciklih, zlasti pri anodah iz litija in kovine, kljub trditvam o zatiranju.

- Trenutne celice dosegajo 350–400 Wh/kg, kar je nižje od 500+ Wh/kg prototipov, zaradi medfaznih izgub in omejitev volumna elektrolitov.

Stroški in ovire pri sprejemanju na trg

- Poltrdne baterije so 40–50 % dražje od tekočih litij-ionskih baterij, predvsem zaradi stroškov trdnega elektrolita in majhnega obsega proizvodnje.

- Pirometalurško recikliranje obnovi le 60–65 % materialov v primerjavi s 85–90 % pri tekočih baterijah, saj obdelava pri visokih temperaturah poškoduje trdne elektrolite.

- Svetovna proizvodnja je pod 2 GWh (2024), s predvidenim tržnim deležem le 1 % do leta 2027, kar odlaga ekonomijo obsega.

Zaključek

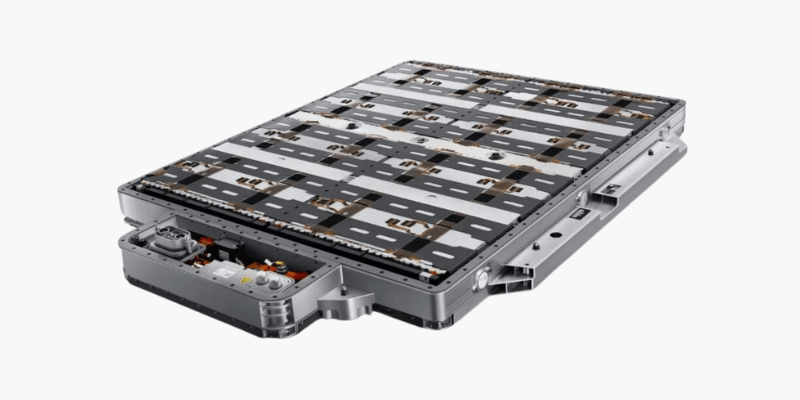

Polprevodniške baterije združujejo varnost in energijsko gostoto polprevodniške tehnologije z možnostjo izdelave tekočih sistemov. Trenutno poganjajo električna vozila (NIO, BMW) in hranilnike v omrežju, pri čemer se pričakuje, da bodo stroški padli na 70 USD/kWh do leta 2030 glede na obseg proizvodnje.

Izzivi, kot sta medfazna odpornost in čistost surovin, ostajajo, vendar stalna R&D jih postavlja kot prevladujočo prehodno tehnologijo, dokler polne polprevodniške baterije niso pripravljene.

Za industrije, ki zahtevajo daljši doseg, hitrejše polnjenje in visoke varnostne standarde, so poltrdne baterije bližnja prihodnost.