แบตเตอรี่กึ่งแข็งซึ่งเป็นเทคโนโลยีแบตเตอรี่ที่เป็นนวัตกรรมมีข้อได้เปรียบมากกว่า แบตเตอรี่ลิเธียม- บทความนี้กำหนดพวกเขาเปรียบเทียบกับแบตเตอรี่ลิเธียมกล่าวถึงประโยชน์และความท้าทายของพวกเขา

แบตเตอรี่กึ่งแข็งคืออะไร?

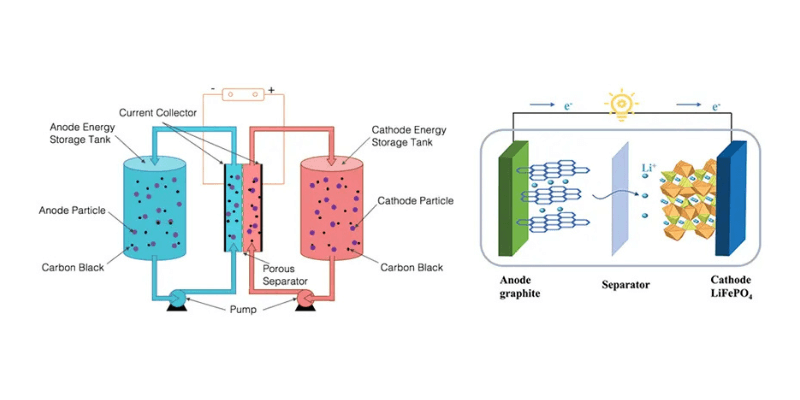

แบตเตอรี่กึ่งแข็งเป็นแบตเตอรี่แบบชาร์จไฟได้ซึ่งใช้กึ่งแข็ง อิเล็กโทรไลต์- อิเล็กโทรไลต์นี้มักจะประกอบด้วยวัสดุนำไฟฟ้าที่เป็นของแข็งที่แขวนอยู่ในของเหลวซึ่งมีข้อได้เปรียบหลายประการมากกว่าการออกแบบทั่วไป

แบตเตอรี่กึ่งแข็งเทียบกับแบตเตอรี่ลิเธียมเหลว

ความแตกต่างหลักระหว่างเทคโนโลยีเหล่านี้อยู่ในองค์ประกอบอิเล็กโทรไลต์ความปลอดภัยและประสิทธิภาพ:

โครงสร้างอิเล็กโทรไลต์

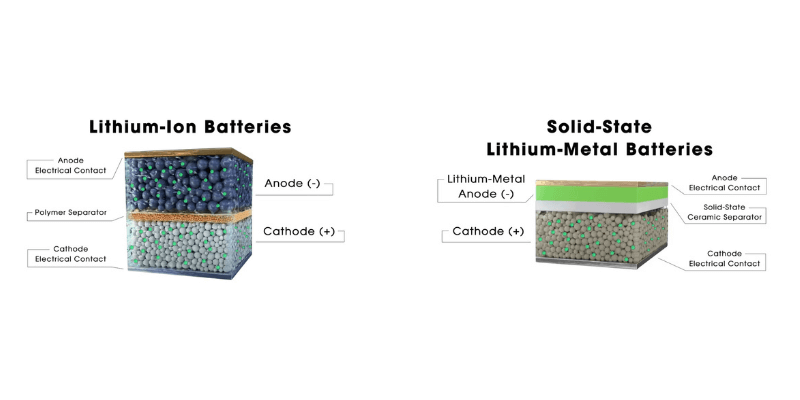

- แบตเตอรี่ลิเธียมเหลว: ใช้อิเล็กโทรไลต์ของเหลวอินทรีย์ไวไฟได้รับความเสี่ยงจากการรั่วไหลและ หนีความร้อน-

- แบตเตอรี่กึ่งแข็ง: ใช้สารเจล/อิเล็กโทรไลต์ที่มีความหนืด/วางลดความติดไฟและช่วยให้ตัวคั่นที่บางกว่า

ความปลอดภัย

- อิเล็กโทรไลต์เหลวสามารถจุดชนวนภายใต้ความเครียด (เช่นความเสียหายทางกายภาพหรือการชาร์จไฟมากเกินไป) นำไปสู่การยิง

- อิเล็กโทรไลต์กึ่งแข็งต้านทานการเจริญเติบโตของ dendrite ทนต่ออุณหภูมิมากกว่า 200 ° C และลดความเสี่ยงในการเผาไหม้ในการทดสอบการเจาะเล็บ

ผลงาน

- ความหนาแน่นของพลังงาน: แบตเตอรี่ลิเธียมเหลวสูงสุดที่ 300 wh/kg; ตัวแปรกึ่งแข็งถึง 350–400 wh/kg

- วงจรชีวิต: แบตเตอรี่ลิเธียมเหลวมีอายุประมาณ 1,200 รอบ; กึ่งแข็งทน 2,000-3,000 รอบด้วยการเก็บกำลังการผลิตมากกว่า 85%

- ช่วงอุณหภูมิ: อิเล็กโทรไลต์ของเหลวแช่แข็งต่ำกว่า 0 ° C หรือข้นในสภาพอากาศเย็น แบตเตอรี่กึ่งแข็งทำงานตั้งแต่ -40 ° C ถึง 60 ° C โดยไม่มีการสูญเสียประสิทธิภาพอย่างมีนัยสำคัญ

การผลิต

แบตเตอรี่ลิเธียมเหลวจะได้รับประโยชน์จากสายการผลิตที่จัดตั้งขึ้นในขณะที่กึ่งแข็งต้องการกระบวนการแก้ไข

ข้อดีของแบตเตอรี่กึ่งแข็ง

แบตเตอรี่กึ่งแข็งมีข้อดีหลายประการมากกว่าแบตเตอรี่ลิเธียมเหลวแบบดั้งเดิม

เพิ่มความปลอดภัย

การลดปริมาณของเหลวและการใช้เฟรมเวิร์กที่เป็นของแข็งลดการก่อตัวของ dendrite และการหลบหนีความร้อน อิเล็กโทรไลต์ที่เพิ่มขึ้นของเซรามิกเช่นซัลไฟด์หรือพอลิเมอร์คอมโพสิตป้องกันการลัดวงจร เซลล์กึ่งแข็งผ่านการทดสอบการเจาะเล็บที่มีความเสี่ยงการเผาไหม้น้อยที่สุดโดยระบุข้อบกพร่องสำคัญในแบตเตอรี่ลิเธียมเหลว

ความหนาแน่นของพลังงานที่สูงขึ้น

แบตเตอรี่กึ่งแข็งทำให้สูงขึ้น 30-40% ความหนาแน่นของพลังงาน กว่าแบตเตอรี่ลิเธียมเหลวโดยใช้ขั้วบวกที่มีความจุสูงเช่นลิเธียมหรือซิลิกอนจับคู่กับแคโทด NMC/NCA ที่อุดมไปด้วยแรงดันสูง

ยืดอายุการใช้งาน & ความยืดหยุ่น

การย่อยสลายอิเล็กโทรดที่ลดลงและอินเทอร์เฟซที่เสถียรช่วยให้สามารถใช้งานได้มากกว่า 2, 000 รอบด้วยการสูญเสียความจุน้อยที่สุด พวกเขายังทำงานได้ดีในความเย็นมาก (–40 ° C) ป้องกันการแช่แข็งอิเล็กโทรไลต์

ความยืดหยุ่น

ตัวแปรกึ่งแข็งใช้อุปกรณ์การผลิตลิเธียมไอออนที่มีอยู่ลดต้นทุนการเปลี่ยนแปลงเมื่อเทียบกับแบตเตอรี่ที่เป็นของแข็ง บริษัท อย่าง BMW และ Ford กำลังเร่งการผลิตโดยการร่วมมือกับ Solid Power

ทำไมแบตเตอรี่กึ่งแข็งจึงมีความหนาแน่นพลังงานสูง?

สามนวัตกรรมช่วยเพิ่ม การจัดเก็บพลังงาน ของแบตเตอรี่กึ่งแข็ง:

นวัตกรรมวัสดุ

- Anodes: โลหะลิเธียม (3,860 mAh/g) หรือคอมโพสิตซิลิกอนแทนที่กราไฟท์ (372 mAh/g)

- แคโทด: NMC สูงหรือลิเธียมที่อุดมไปด้วยออกไซด์เพิ่มแรงดันไฟฟ้าและความจุ

การเพิ่มประสิทธิภาพอิเล็กโทรไลต์

- การออกแบบคู่เฟส (เช่นเจลพอลิเมอร์ที่มีฟิลเลอร์เซรามิก) ลดส่วนประกอบเฉื่อย, เพิ่มพื้นที่สำหรับวัสดุที่ใช้งานมากที่สุด

- การแข็งตัวในแหล่งกำเนิดช่วยเพิ่มการสัมผัสอิเล็กโทรดอิเล็กโทรไลต์และลดความต้านทานภายใน

ประสิทธิภาพเชิงโครงสร้าง

อิเล็กโทรดมีเมทริกซ์ที่มีรูพรุนเพื่อเก็บวัสดุที่ใช้งานมากขึ้นในขณะที่เส้นทางไอออนที่สั้นกว่าในการออกแบบขนาดกะทัดรัดช่วยเพิ่มความหนาแน่นของพลังงาน

ความท้าทายของแบตเตอรี่กึ่งแข็ง

ในขณะที่แบตเตอรี่กึ่งแข็งมีแนวโน้ม แต่พวกเขาเผชิญกับความท้าทายบางอย่างที่จะเอาชนะ

ความซับซ้อนของวัสดุและซัพพลายเชน

- อิเล็กโทรไลต์ของแข็งที่มีความบริสุทธิ์สูงเช่นซัลไฟด์และออกไซด์ต้องใช้ระดับความบริสุทธิ์สูงกว่า 99. 99% และการจัดการพิเศษเนื่องจากความไวความชื้นลดลงกว่า 20 ppm สิ่งนี้ต้องใช้ที่เก็บข้อมูลอาร์กอนที่มีการเพิ่มต้นทุนและความซับซ้อนด้านลอจิสติกส์

- วัสดุเหล่านี้ต้องการสารยึดเกาะ PTFE มากกว่า PVDF ทั่วไป 40% ซึ่งเป็นโซ่อุปทานทางเคมีที่รัดไว้

คอขวดการผลิต

- การทำปฏิทินอิเล็กโทรดจะต้องจัดการความหนาแน่นที่สูงขึ้น 15-20% โดยเวลาการอบแห้งลดลงจาก 12–24 ชั่วโมงเป็น 2-3 ชั่วโมงซึ่งจำเป็นต้องมีสายการผลิตติดตั้ง

- ความต้านทานต่อการเชื่อมต่อจากการสัมผัสอิเล็กโทรดอิเล็กโทรดอิเล็กโทรไลต์ของแข็งสามารถเพิ่มความต้านทานภายในได้มากถึง 300%ลดประสิทธิภาพและความสามารถในการชาร์จอย่างรวดเร็ว

- เทคนิคการแข็งตัวในแหล่งกำเนิดต่อสู้เพื่อให้ได้อินเตอร์เฟสอิเล็กโทรดอิเล็กโทรไลต์แบบสม่ำเสมอซึ่งส่งผลกระทบต่ออายุการใช้งานของวัฏจักรและความเสถียรของประสิทธิภาพ

ข้อ จำกัด ด้านประสิทธิภาพ

- อิเล็กโทรไลต์ไฮบริดแสดงค่าการนำไฟฟ้าไอออนิกต่ำกว่าของเหลวที่อุณหภูมิต่ำกว่าศูนย์ 10-30% ซึ่ง จำกัด กำลังไฟในสภาพอากาศเย็น

- ความเสี่ยงของลิเธียม dendrite ยังคงมีอยู่แม้หลังจาก 500 รอบกว่า 500 รอบโดยเฉพาะอย่างยิ่งกับขั้วบวกลิเธียม-โลหะแม้จะมีการเรียกร้องการปราบปราม

- เซลล์ปัจจุบันบรรลุ 350–400 wh/kg ต่ำกว่าต้นแบบ 500+ wh/kg ของต้นแบบเนื่องจากการสูญเสีย interfacial และข้อ จำกัด ปริมาณอิเล็กโทรไลต์

อุปสรรคด้านต้นทุนและการยอมรับในตลาด

- แบตเตอรี่กึ่งแข็งมีราคาแพงกว่าแบตเตอรี่ลิเธียมไอออนของเหลว 40-50% ส่วนใหญ่เป็นผลมาจากต้นทุนอิเล็กโทรไลต์ที่เป็นของแข็งและปริมาณการผลิตต่ำ

- การรีไซเคิล Pyrometallurgical กู้คืนได้เพียง 60–65% ของวัสดุเมื่อเทียบกับ 85–90% สำหรับแบตเตอรี่ของเหลวเนื่องจากการประมวลผลอุณหภูมิสูงความเสียหายอิเล็กโทรไลต์ที่เป็นของแข็ง

- การผลิตทั่วโลกอยู่ภายใต้ 2 GWH (2024) โดยมีส่วนแบ่งการตลาดที่คาดการณ์ไว้เพียง 1% ในปี 2027 ทำให้การประหยัดจากขนาดชะลอตัว

บทสรุป

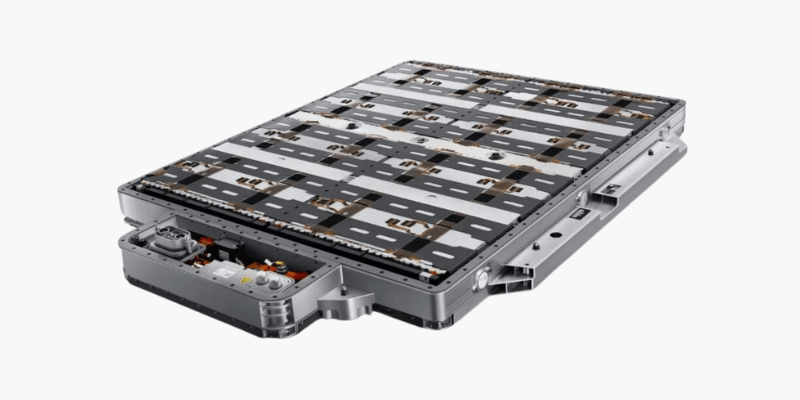

แบตเตอรี่กึ่งแข็งรวมความปลอดภัยและความหนาแน่นพลังงานของเทคโนโลยีโซลิดสเตตเข้ากับความสามารถในการผลิตของระบบของเหลว ขณะนี้พวกเขาใช้พลังงาน EVS (NIO, BMW) และที่เก็บกริดโดยคาดว่าค่าใช้จ่ายจะลดลงเป็น $ 70/kWh ภายในปี 2573 เป็นเครื่องชั่งผลิต

ความท้าทายเช่นความต้านทานต่อการแทรกซึมและความบริสุทธิ์ของวัตถุดิบยังคงอยู่ แต่อย่างต่อเนื่อง R&D วางตำแหน่งเป็นเทคโนโลยีการเปลี่ยนผ่านที่โดดเด่นจนกระทั่งแบตเตอรี่โซลิดสเตตเต็มรูปแบบพร้อม

สำหรับอุตสาหกรรมที่ต้องการระยะยาวการชาร์จที่เร็วขึ้นและมาตรฐานความปลอดภัยสูงแบตเตอรี่กึ่งแข็งเป็นอนาคตอันใกล้