Vòng đệm rất cần thiết cho sự an toàn và hiệu suất của thiết bị trong các ngành công nghiệp khác nhau. Chúng cung cấp khả năng chống thấm và duy trì tính toàn vẹn của vỏ điện tử.

Trong bài đăng này, chúng ta sẽ thảo luận về lý do tại sao các miếng đệm lại quan trọng, vật liệu nào phù hợp nhất với các ứng dụng khác nhau và cách thiết kế các miếng đệm.

Tại sao miếng đệm lại quan trọng?

Các miếng đệm lấp đầy khoảng trống giữa các bề mặt và bù đắp những điểm bất thường để duy trì tính toàn vẹn và hiệu quả của hệ thống. Chúng tạo ra lớp bịt kín giúp đạt được xếp hạng IP (Bảo vệ chống xâm nhập) cụ thể chống lại nước, bụi và vật thể lạ.

Ngoài ra, các miếng đệm làm giảm độ rung và tiếng ồn đồng thời ngăn chặn các chất gây ô nhiễm như bụi.

Vật liệu đệm thông thường và ứng dụng của chúng

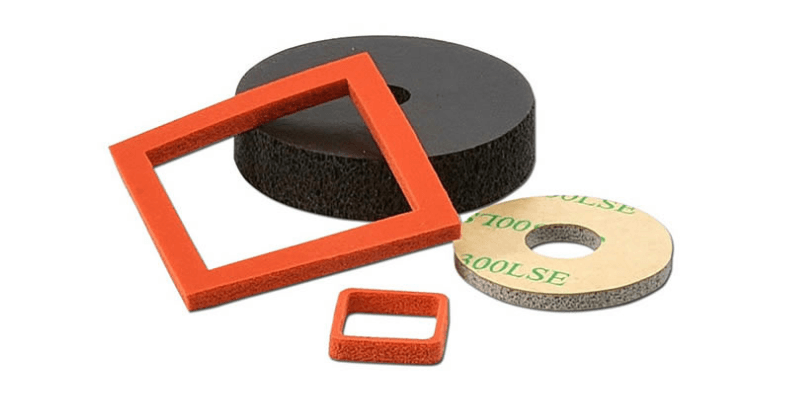

Việc chọn vật liệu phù hợp rất quan trọng đối với hiệu suất của miếng đệm trong các điều kiện cụ thể. Dưới đây là tổng quan về các miếng đệm phổ biến và điểm mạnh của chúng:

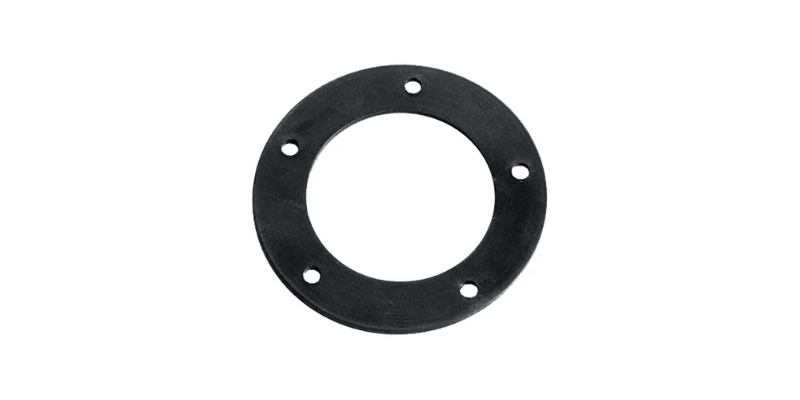

Vòng đệm cao su

- Tốt nhất cho: Các ứng dụng yêu cầu tính linh hoạt, độ bền và khả năng chống dầu, hóa chất và nước.

- Vật liệu: Silicone, cao su tổng hợp, EPDM, nitrile, v.v.

- Lợi ích chính: Các miếng đệm cao su duy trì hình dạng trong quá trình lắp ráp và tháo rời thường xuyên mà không bị biến dạng vĩnh viễn. Phổ biến trong môi trường công nghiệp, chúng có thể được ép phun hoặc cắt khuôn thành các hình dạng tùy chỉnh.

Vòng đệm xốp

- Tốt nhất cho: Các tình huống cần đệm, cách nhiệt hoặc khả năng thích ứng với các bề mặt không bằng phẳng.

- Vật liệu: Bọt xốp hở và bọt xốp kín.

- Những lợi ích chính: Nhẹ và linh hoạt, miếng đệm xốp có loại dạng ô mở và dạng ô kín. Bọt xốp dạng ô mở mềm hơn cho các cấu hình độc đáo, trong khi bọt dạng ô kín mang lại mật độ cao hơn và khả năng chống chịu ngoài trời cao hơn. Chúng lý tưởng cho việc cách nhiệt và giảm rung.

Vòng đệm kim loại

- Tốt nhất cho: Môi trường áp suất cao và nhiệt độ cao.

- Vật liệu: Thép không gỉ, đồng, nhôm và các kim loại khác.

- Lợi ích chính: Miếng đệm kim loại hoạt động tốt ở những nơi cao su hoặc bọt bị hỏng. Họ cung cấp sức mạnh và độ bền chưa từng có. Thường được sử dụng trong động cơ ô tô, hệ thống hàng không vũ trụ và máy móc hạng nặng, miếng đệm kim loại dễ dàng chịu được áp suất và nhiệt độ khắc nghiệt.

Ứng dụng của miếng đệm trong các ngành công nghiệp

Vòng đệm được sử dụng trong hầu hết các ngành công nghiệp. Dưới đây là một vài ví dụ:

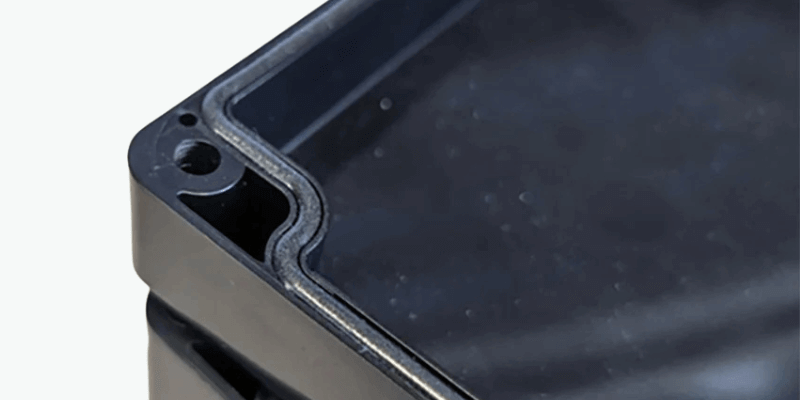

Bao vây

Các miếng đệm, từ hộp nối điện đến các thiết bị chiếu sáng ngoài trời, bảo vệ các bộ phận quan trọng khỏi độ ẩm và bụi. Chọn miếng đệm được xếp hạng IP67 hoặc cao hơn để bảo vệ chắc chắn.

Công tắc màng

Trong các thiết bị điện tử, các miếng đệm kết hợp với công tắc màng mang lại phản hồi xúc giác và bảo vệ môi trường. Chúng ngăn hơi ẩm và bụi xâm nhập vào thiết bị, bảo vệ các mạch bên trong.

Đầu nối bên ngoài

Thiết bị điện tử hàng hải, bộ sạc ô tô và các thiết bị tương tự dựa vào các miếng đệm để tạo ra các vòng kín nước. Vòng chữ O nhỏ thường được sử dụng vì hạn chế về không gian.

Vòng đệm phẳng so với vòng chữ O: Sự khác biệt là gì?

Không phải mọi ứng dụng đều yêu cầu miếng đệm giống nhau. Hiểu về các miếng đệm phẳng và vòng chữ O sẽ giúp bạn lựa chọn phương án phù hợp.

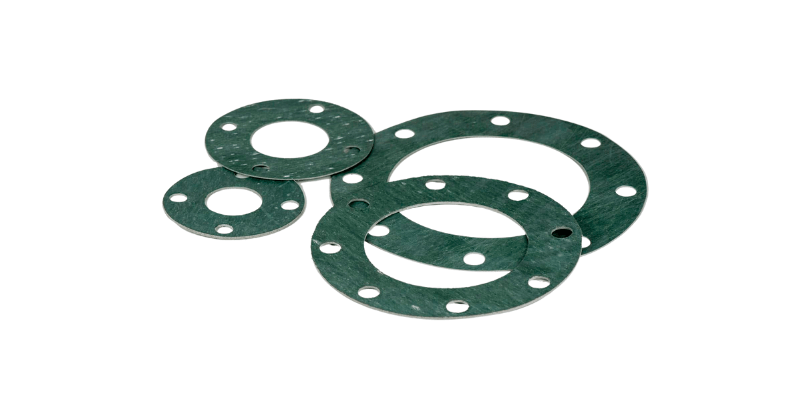

Vòng đệm phẳng

- Hình dạng & Công dụng: Được làm từ các tấm phẳng bằng cao su, xốp hoặc kim loại, chúng bịt kín các bề mặt phẳng và có thể được tùy chỉnh cho các thiết kế phức tạp.

- Ứng dụng lý tưởng: Vỏ tùy chỉnh, bề mặt giao phối không đều hoặc môi trường áp suất thấp.

Nhẫn chữ O

- Hình dạng & Công dụng: Vòng chữ O hình tròn và hình xuyến vừa khít với các rãnh và nén lại để tạo thành vòng đệm kín.

- Ứng dụng lý tưởng: Các hệ thống động như thủy lực hoặc khí nén; giới hạn ở các vật liệu linh hoạt như silicone hoặc cao su tổng hợp.

Các yếu tố chính cần xem xét khi lựa chọn một miếng đệm

Chọn sai miếng đệm có thể dẫn đến những thất bại tốn kém. Để tránh điều này, hãy xem xét các yếu tố sau:

Khả năng tương thích vật liệu

Hãy kết hợp vật liệu với môi trường của nó, chẳng hạn như:

- Sử dụng silicone cho nhiệt độ cao.

- Chọn nitrile để kháng dầu và nhiên liệu.

- Chọn EPDM để chống tia cực tím và thời tiết ngoài trời.

Điều kiện hoạt động

Đánh giá nhiệt độ, áp suất và mức độ tiếp xúc với hóa chất hoặc mài mòn; một miếng đệm phù hợp với áp suất thấp có thể bị hỏng ở cài đặt áp suất cao.

Bề mặt hoàn thiện và dung sai

Bề mặt gồ ghề cần vật liệu mềm hơn như bọt hoặc cao su, trong khi bề mặt nhẵn có thể sử dụng vật liệu cứng hơn như kim loại.

Yêu cầu nén

Các vật liệu khác nhau có nhu cầu nén khác nhau; nén quá mức có thể làm mất khả năng bịt kín, trong khi nén quá mức có thể dẫn đến rò rỉ.

Mẹo thiết kế để tối đa hóa hiệu suất của miếng đệm

Ngay cả miếng đệm tốt nhất cũng không hoạt động tốt nếu được lắp đặt hoặc thiết kế không đúng cách. Hãy làm theo những lời khuyên sau để có hiệu suất tối ưu:

1. Phân bổ không gian để mở rộng

Đảm bảo đủ chỗ cho miếng đệm nở ra khi bị nén; nén quá mức có thể làm hỏng nó và làm hỏng con dấu.

2. Đạt được độ nén đồng đều

Nén không đồng đều tạo ra các điểm yếu có thể dẫn đến rò rỉ. Gia cố các bề mặt tiếp xúc hoặc điều chỉnh độ dày của miếng đệm để phân bổ áp suất đều.

3. Kiểm tra điều kiện thực tế

Trước khi hoàn thiện thiết kế của bạn, hãy kiểm tra miếng đệm trong các điều kiện như nhiệt độ cực cao, độ rung và tiếp xúc với hóa chất.

Phần kết luận

Vòng đệm có thể nhỏ nhưng chúng có tác dụng đáng kể. Chúng bảo vệ các thiết bị điện tử tinh vi và bịt kín các hệ thống áp suất cao trong các ứng dụng khác nhau.

Hiểu các loại miếng đệm khác nhau, vật liệu của chúng và các yếu tố hiệu suất sẽ giúp bạn đưa ra những lựa chọn sáng suốt. Việc lựa chọn gioăng phù hợp đảm bảo độ tin cậy, an toàn và yên tâm.