Sau khi hoàn thành hơn 6.000 Các dự án pin lithium tùy chỉnh, chúng tôi thấy rằng khách hàng thường có câu hỏi cụ thể. Trong bài viết này, chúng tôi sẽ đi sâu vào các câu hỏi và câu trả lời cần thiết liên quan đến Thiết kế và sản xuất bộ pin lithium-ion.

Các yếu tố chính cần xem xét khi chọn bộ pin lithium-ion tùy chỉnh là gì?

Khi chọn một bộ pin lithium-ion tùy chỉnh, điều cần thiết là phải xem xét một số yếu tố chính.

Trước hết, mật độ năng lượng đóng một vai trò quan trọng, vì khách hàng thường tìm kiếm pin lithium-ion cho các ứng dụng di động, mong muốn công suất năng lượng cao trong thiết kế nhỏ gọn và nhẹ.

Hơn nữa, tỷ lệ xả nên được tính đến. Có hai loại tế bào ion chính – Tế bào năng lượng và các tế bào năng lượng. Các tế bào năng lượng cung cấp mật độ năng lượng cao nhưng việc phân phối dòng điện thấp hơn, dẫn đến thời gian chạy dài hơn, trong khi các tế bào điện cung cấp sản lượng hiện tại cao nhanh với mật độ năng lượng thấp hơn.

Cuộc sống chu kỳ là một khía cạnh quan trọng khác để xem xét. Các tế bào phosphate lithium-ion, mặc dù có khả năng nặng hơn, có thể cung cấp hơn 3.000 chu kỳ, vượt qua 500-600 chu kỳ của các loại khác.

An toàn là tối quan trọng đối với tất cả các pin lithium-ion, với các tế bào phosphate lithium-ion được biết đến với sự mạnh mẽ nâng cao về các tính năng an toàn.

Hơn nữa, khả năng chịu nhiệt độ là một cân nhắc quan trọng. Mặc dù pin lithium trước đây bị giới hạn trong các ứng dụng nhiệt độ cao, nhưng các tiến bộ hiện cho phép sử dụng chúng trong các cài đặt khác nhau với nhiệt độ cao.

Làm thế nào có thể tích hợp quản lý nhiệt vào gói lithium tùy chỉnh?

Vỏ lớn hơn thường tản nhiệt tốt hơn và đôi khi chúng tôi bổ sung thêm bộ tản nhiệt trong gói để quản lý lượng nhiệt dư thừa.

Phương pháp làm mát chủ động của Tesla đặt ra tiêu chuẩn cao trong ngành, sử dụng sự tuần hoàn chất lỏng xung quanh từng tế bào để duy trì nhiệt độ đồng đều và loại bỏ sự chênh lệch nhiệt. Hệ thống tiên tiến này đảm bảo các tế bào bên trong phù hợp với nhiệt độ của các tế bào bên ngoài, thậm chí cho phép làm nóng trước vào những ngày lạnh để cải thiện hiệu quả và tuổi thọ.

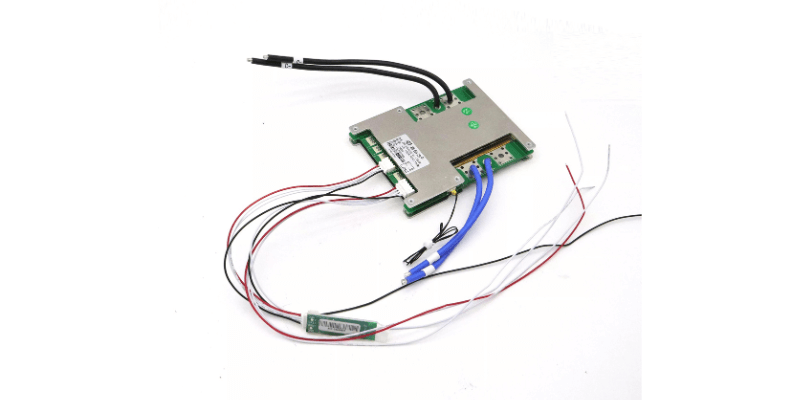

Nếu hạn chế về ngân sách hạn chế các lựa chọn làm mát, việc tận dụng cảm biến nhiệt độ có thể là một giải pháp tiết kiệm chi phí. Những cảm biến này có thể theo dõi sự thay đổi nhiệt độ và điều chỉnh hoạt động của thiết bị cho phù hợp, chẳng hạn như điều chỉnh bộ xử lý hoặc điều chỉnh tốc độ động cơ để tránh quá nóng.

Ngoài ra, việc triển khai hệ thống cảnh báo trong bộ pin có thể giúp cảnh báo người dùng về các vấn đề nhiệt độ tiềm ẩn và thực hiện các biện pháp phòng ngừa hiệu quả.

Những tính năng an toàn nào ít phổ biến hơn nên được đưa vào pin lithium tùy chỉnh?

Các tính năng an toàn cấp hai và cấp ba thường không được chú ý, nhưng một khía cạnh quan trọng là cân bằng tế bào.

Nhiều người coi đây là một tính năng của vòng đời, tương tự như việc đổ đầy đều một khay đá để đảm bảo tất cả các ô đều duy trì mức độ bằng nhau. Sự cân bằng này giúp kéo dài tuổi thọ của gói và ngăn không cho từng tế bào giảm quá thấp hoặc tăng quá cao, điều này có thể kích hoạt các mạch an toàn và giảm nhận thức về thời gian chạy.

Ngoài ra, nếu mạch an toàn gặp trục trặc, việc dịch chuyển liên tục ở mức thấp hoặc cao có thể dẫn đến sự phát triển đuôi gai hoặc các vấn đề với vật liệu phân tách, có khả năng gây đoản mạch bên trong. Vì vậy, cân bằng tế bào thực sự là một tính năng an toàn.

Các cân nhắc khác bao gồm việc đóng gói pin bằng van giảm áp hiệu quả. Nó có thể giúp giảm thiểu nguy cơ quá áp trong bộ pin, đặc biệt là khi sạc nhanh hoặc trong trường hợp xảy ra sự cố.

Cuối cùng, việc sử dụng vật liệu chống cháy chịu được nhiệt độ cao sẽ đảm bảo rằng các thành phần không bốc cháy trong các tình huống thất bại. Những tính năng an toàn ít được biết đến này đóng một vai trò quan trọng đối với hiệu suất và độ tin cậy của pin.

Hầu hết các tiêu chuẩn sản phẩm cuối cùng có yêu cầu pin phải đáp ứng các tiêu chuẩn cụ thể không?

Có, hầu hết các tiêu chuẩn về sản phẩm cuối cùng đều yêu cầu pin phải đáp ứng các tiêu chí về an toàn, hiệu suất và chất lượng cụ thể để đảm bảo sự an toàn cho người tiêu dùng và độ tin cậy của sản phẩm. Các cơ quan quản lý thực thi các tiêu chuẩn này để giảm thiểu rủi ro như nguy cơ hỏa hoạn, sự thoát nhiệt, và tác động môi trường.

Các tiêu chuẩn chính bao gồm:

- VÀ 38,3: Bao gồm các yêu cầu kiểm tra để vận chuyển an toàn pin lithium.

- IEC 62133: Chỉ định các yêu cầu an toàn đối với pin lithium ion trong thiết bị điện tử cầm tay.

- IEC 62619: Tập trung vào sự an toàn của pin và pin lithium-ion thứ cấp trong các ứng dụng công nghiệp.

- UL1642 và UL 2054: Tiêu chuẩn an toàn cho pin lithium dùng trong gia đình và công nghiệp.

- Dấu CE: Cho biết sự phù hợp với các tiêu chuẩn an toàn của EU.

Việc tuân thủ là cần thiết để ngăn chặn việc thu hồi, trách nhiệm pháp lý và gây tổn hại đến danh tiếng thương hiệu; các nhà sản xuất phải tuân thủ các tiêu chuẩn này để cung cấp các sản phẩm chạy bằng pin an toàn.

Bạn có đề xuất tìm kiếm tế bào trực tuyến cho hoạt động sản xuất nội bộ không? Có đơn giản như việc sử dụng Google để tìm các tùy chọn đáp ứng yêu cầu của tôi không?

Mặc dù Google có thể là điểm khởi đầu nhưng đây là những đề xuất để tìm nhà cung cấp thiết bị di động đáng tin cậy:

- Hợp tác với nhà cung cấp pin uy tín được biết đến với chất lượng pin và hỗ trợ đáng tin cậy.

- Xác nhận các thông số kỹ thuật rõ ràng, bao gồm điện áp, công suất, mật độ năng lượng, vòng đời, kích thước, trọng lượng và các tính năng an toàn để thu hẹp tìm kiếm của bạn.

- Đảm bảo khả năng tương thích với hệ thống của bạn bằng cách xem xét sự phù hợp về mặt cơ học, kết nối điện và các giao thức sạc/xả để tránh các vấn đề tích hợp trong quá trình sản xuất.

- Chọn các tế bào đáp ứng các tiêu chuẩn ngành được công nhận như UL hoặc IEC để đảm bảo an toàn và hiệu suất; xem lại bảng dữ liệu sản phẩm hoặc báo cáo thử nghiệm từ nhà cung cấp.

- Tham khảo ý kiến của các chuyên gia, kỹ sư hoặc nhà tư vấn trong ngành có kinh nghiệm tìm nguồn cung ứng pin cho sản xuất. Họ có thể hướng dẫn bạn chọn ô phù hợp với nhu cầu cụ thể của bạn.

- Đánh giá hậu cần vận chuyển liên quan đến các lựa chọn, thời gian giao hàng, chi phí và yêu cầu giao hàng.

Làm thế nào để bạn xác định vòng đời của sản phẩm?

Nói chung, việc xác định tuổi thọ của pin bao gồm một số phương pháp:

- Thông số kỹ thuật của nhà sản xuất: Kiểm tra vòng đời ước tính của nhà sản xuất, thường dựa trên thử nghiệm tiêu chuẩn hóa. Tuy nhiên, những giá trị này thường phản ánh dòng điện ở trạng thái ổn định thấp.

- Kiểm tra lão hóa tăng tốc: Tiến hành kiểm tra trong điều kiện được kiểm soát bằng cách sạc và xả pin liên tục trong khi theo dõi hiệu suất và sự suy giảm dung lượng. Phương pháp này ước tính pin có thể chịu đựng được bao nhiêu chu kỳ trước khi đạt đến ngưỡng dung lượng cụ thể (ví dụ: 80% dung lượng ban đầu).

- Dữ liệu và kinh nghiệm trong quá khứ: Dữ liệu lịch sử về các loại pin tương tự có thể cung cấp cái nhìn sâu sắc về vòng đời dự kiến thông qua nghiên cứu trong ngành và nghiên cứu trường hợp, mặc dù phương pháp này đưa ra ước tính sơ bộ.

- Hóa học và thiết kế pin: Các loại hóa chất khác nhau có đặc điểm vòng đời khác nhau; hiểu những điều này cùng với các yếu tố thiết kế như điện cực vật liệu có thể đưa ra ước tính sơ bộ về hiệu suất.

- Điều kiện hoạt động: Các yếu tố như tốc độ xả, độ sâu xả (DOD), giao thức sạc và điều kiện môi trường ảnh hưởng đáng kể đến tuổi thọ của vòng đời.

Mặc dù các phương pháp này cung cấp ước tính sơ bộ nhưng thử nghiệm thực tế phù hợp với các điều kiện cụ thể là cách đáng tin cậy nhất để xác định tuổi thọ của pin, đặc biệt đối với các sản phẩm ngoài trời có nhiệt độ khắc nghiệt.