الوجبات السريعة الرئيسية:

- اختيار كيمياء الخلايا: يؤثر على الأداء والسلامة والعمر والتكلفة ؛ توفر الكيميائيات المستندة إلى الليثيوم كثافة عالية الطاقة وعمر دورة طويلة ولكن قد تتطلب BMS معقدة.

- السمات المادية: الوزن والحجم وعدد الخلايا تؤثر على قابلية النقل والتصميم والتكاليف ؛ قد تزيد متطلبات الجهد الأعلى من حجم الحزمة.

- تصميم العلبة: يجب استيعاب نوع الخلية والمكونات الداخلية ودوائر السلامة ؛ أرصدة اختيار المواد التكلفة والقوة والمقاومة البيئية.

- تقنية بوتينغ: يعزز القدرة على التكيف البيئي والأداء ولكنه يضيف إلى التكلفة ؛ يبرر النفقات من خلال تحسين المتانة والموثوقية.

- حزم البطارية الذكية: توفر مراقبة الحالة في الوقت الفعلي والميزات المتقدمة مثل أجهزة الشحن المدمجة والمراقبة عن بُعد ، ولكنها قد تزيد من التعقيد والتكلفة.

- شهادة البطارية: يضمن السلامة والامتثال التنظيمي ، ولكنه ينطوي على اختبارات وتكاليف إضافية ؛ تشمل الاستراتيجيات تقييم الاحتياجات والحلول البديلة.

عند تطوير أ حزمة بطارية مخصصة، غالبًا ما يكون القلق الرئيسي هو النفقات المقدمة ، حيث تؤثر في النهاية على تسعير المنتج النهائي وقابلية السوق.

إذا تجاوزت تكلفة حزمة البطارية ما يرغب السوق في دفعه ، فسيؤدي ذلك إلى انخفاض مبيعات. علاوة على ذلك ، إذا فشل الاستثمار الأولي في إظهار عائد استثمار قابل للتطبيق ، فقد تكون جدوى المشروع بأكملها موضع تساؤل.

لذلك ، فإن فهم سائقي تكلفة حزمة البطارية أمر ضروري. يمكن أن يساعدك في اختيار المكونات المناسبة وكيمياء الخلايا دون تجاوز الميزانيات.

تشمل برامج تشغيل التكلفة الرئيسية:

- اختيار كيمياء الخلايا

- الوزن والحجم وعدد الخلايا

- تصميم العلبة وإطالة البطارية

- ميزات حزمة البطارية الذكية

- متطلبات شهادة البطارية

اختيار كيمياء الخلايا المناسبة

الخطوة الأولية في إنشاء حزمة بطارية مخصصة هي اختيار كيمياء البطارية المناسبة. إنه يؤثر بشكل مباشر على قدرة البطارية على توفير الطاقة بأمان وكفاءة ، مما يؤثر على عمرها وتكلفةها الإجمالية.

نظرة عامة على كيمياء الخلايا

حاليا ، كيمياء البطارية الرئيسية هي النيكل-كاديميوم (NICD) ، هيدريد النيكل المعدني (NIMH) ، و القائم على الليثيوم الكيميائيات ، مثل الليثيوم أيون (LI-ION) والليثيوم بوليمر (LI-PO). كل كيمياء لها خصائص فريدة وتطبيق.

خلية NICD

- الجهد: 1.2 فولت/الخلية

- كثافة الطاقة: منخفضة

- مقاومة مفرطة وتفريغ الإفراط في التفريغ: قوي

- التكلفة: منخفضة

- التأثير البيئي: يحتوي على الكادميوم ، وهو ضار للبيئة

- التطبيق النموذجي: الأدوات الكهربائية ، والأجهزة المحمولة ، مثل مكافعي الفراغ المحمولة

خلية نيمه

- الجهد: 1.2 فولت/الخلية

- كثافة الطاقة: أعلى من NICD

- تأثير الذاكرة: لا شيء ؛ لا حاجة لتفريغ كامل

- التكلفة: معتدلة

- تطبيق نموذجي: البطاريات المساعدة للسيارات الهجينة والأجهزة الإلكترونية المحمولة وبعض الألعاب الكهربائية والطائرات النموذجية

الخلية الليثيوم أيون (لي أيون)

- الجهد: 3.6 فولت/خلية أو 3.7 فولت/خلية

- كثافة الطاقة: عالية جدا

- دورة دورة: طويلة

- معدل تفريغ الذات: منخفض

- التطبيق النموذجي: الهواتف الذكية الحديثة والأجهزة اللوحية وأجهزة الكمبيوتر المحمولة ومحطات العمل المحمولة والسيارات الكهربائية والسيارات الهجينة والطائرات بدون طيار عالية الأداء

الخلية الليثيوم بوليمر (LI-PO)

- الجهد: 3.7 فولت/الخلية

- كثافة الطاقة: عالية جدًا ، وعادة ما تكون أعلى من li-ion

- شكل قابل للتخصيص: يمكن تصميم احتياجات محددة من حيث الشكل والحجم

- خفيفة الوزن: أخف من لي أيون

- التطبيق النموذجي: الطائرات التي يتم التحكم فيها عن بُعد ، وسيارات السباقات الكهربائية ، وسيارات طرازات عالية الأداء ، وأجهزة يمكن ارتداؤها ومنتجات إلكترونية مرنة

الاستقرار الكيميائي والمتانة

بالإضافة إلى التكلفة والجهد ، فكر في الاستقرار الكيميائي ومتانة البطارية عند اختيار كيمياء.

توفر الخلايا المستندة إلى الليثيوم عمومًا مادة كيميائية أفضل الاستقرار وعمر أطول ولكن قد تتطلب أنظمة إدارة بطارية أكثر تعقيدًا (نظام إدارة المباني) لضمان السلامة وتحسين الأداء.

وبالمقارنة ، قد لا تؤدي البطاريات المستندة إلى النيكل ، على الرغم من أنها مستقرة كيميائيًا ، وكذلك البطاريات القائمة على الليثيوم في ظل ظروف عالية التحميل أو درجة الحرارة العالية.

الوزن والحجم وعدد الخلايا المطلوبة

السمات المادية مثل الوزن والحجم تؤثر بشكل كبير على التكلفة الإجمالية لحزمة البطارية. لا يرتبط الوزن الكلي وحجم حزمة البطارية فقط بتصميم المنتج وتصميمه ولكنه يؤثر أيضًا على النقل و تصنيع التكاليف.

مطابقة الجهد

كيمياء الخلايا المختلفة تأتي مع الفولتية المحددة مسبقا.

على سبيل المثال ، توفر الخلايا المستندة إلى النيكل 1.2 فولت لكل منهما ، بينما توفر خلايا الليثيوم أيون حوالي 3.6 فولت. إذا كان التطبيق يتطلب جهدًا أعلى ، فيمكن تحقيق ذلك عن طريق زيادة عدد البطاريات بدلاً من اختيار بطارية واحدة عالية الجهد. يمكن أن يقلل هذا النهج من التكاليف إلى حد ما ولكنه سيزيد أيضًا من وزن وحجم حزمة البطارية.

التوازن بين الفضاء والوزن

عند تصميم حزمة بطارية ، تحتاج إلى النظر في القيود المكانية إذا كانت كذلك.

إذا كانت المساحة محدودة ، فقد يكون من الضروري اختيار الخلايا ذات حجم أصغر وكثافة طاقة أعلى ، مما يعني عادة تكاليف أعلى.

من ناحية أخرى ، إذا كانت هناك قيود على الوزن ، فقد يكون من الضروري اختيار خلايا أخف ، حتى لو كان هذا يعني التضحية ببعض كثافة الطاقة.

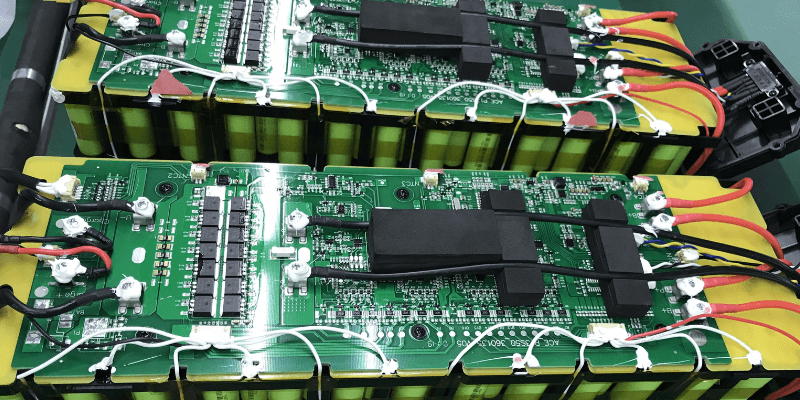

تصميم العلبة وتكنولوجيا بوتينج

يعد تصميم مجموعة حزمة البطارية وتكنولوجيا Potting جانبًا رئيسيًا لضمان السلامة والتشغيل المستقر للبطارية.

إنهم لا يحميون حزمة البطارية فحسب ، بل يلعبون أيضًا دورًا في إدارة التكاليف وأداء المنتج العام. يمكن أن يعزز مخطط العلبة المصممة جيدًا و potting متانة وموثوقية حزمة البطارية مع التكيف مع بيئات التطبيق المختلفة.

العوامل الرئيسية في تصميم العلبة

يحتاج تصميم حاوية حزمة البطارية إلى النظر في الجوانب الرئيسية التالية:

- مساحة التطبيق: تؤثر المساحة المتاحة بشكل مباشر على تصميم وحجم العلبة.

- نوع الخلية: الاختيار بين خلايا أسطواني أو منشورية سوف تؤثر على الهيكل الداخلي وطريقة التثبيت في العلبة.

- المكونات الداخلية: بصرف النظر عن البطاريات ، يجب أن تستوعب العلبة دوائر واقية وأجهزة استشعار درجة الحرارة والجهد/الشاشات الحالية والمكونات الداخلية الأخرى.

- دوائر السلامة: لا سيما بالنسبة للبطاريات القائمة على الليثيوم ، هناك حاجة إلى دوائر السلامة لمنع الإفراط في الشحن ، والإفراط في التخلص من الشحن ، والدوائر القصيرة.

- اختيار المواد: يجب أن يوازن اختيار المواد الخاصة بالتجمع التكلفة والقوة ومقاومة درجة الحرارة والقدرة على التكيف البيئي.

اختيار المواد وفعالية التكلفة

المعدن مقابل البلاستيك

توفر الحاويات المعدنية مقاومة تأثير أقوى وتسامحها في درجة الحرارة ولكنها أكثر تكلفة. الحاويات البلاستيكية أقل تكلفة ولكنها قد تتحلل في درجات الحرارة القصوى.

خيارات المواد البلاستيكية

يعد ABS Plastic خيارًا فعالًا من حيث التكلفة ولكنه يمكن أن يصبح هشًا في درجات حرارة منخفضة. يتم تصنيع العبوات البلاستيكية بشكل شائع باستخدام صب الحقن ، وهي طريقة من حيث التكلفة للإنتاج الضخم.

تقنيات العلبة الاقتصادية

يمكن أن يكون التغليف أو البلاستيك المتناسق في PVC بمثابة حلول أكثر ملاءمة للميزانية ، وخاصة مناسبة للتصميمات التي يتم تضمين حزمة البطارية داخل المنتج.

تطبيق تقنية Potting

تعتبر تقنية Potting وسيلة مهمة لتعزيز القدرة على التكيف البيئي وأداء حزمة البطارية:

- مقاومة للماء ومقاومة للتآكل: بالنسبة للمنتجات التي قد تتعرض للمياه أو المذيبات أو البيئات المسببة للتآكل ، يمكن أن توفر الوصية حماية ضرورية.

- مقاومة التأثير والاهتزاز: يمكن لحزمة البطارية ، المحمية بمواد بوتينغ ، أن تحمل الصدمات والاهتزازات الخارجية بشكل أفضل.

- تحسين الأداء: يمكن أن يحسن Potting الإدارة الحرارية للبطارية ، مما يقلل من تأثير درجة الحرارة على الأداء.

اعتبارات التكلفة ل potting

بينما تعزز تقنية Potting أداء حزمة البطارية وموثوقيتها ، فإنها تضيف أيضًا إلى التكلفة الإجمالية.

خلال مرحلة التصميم ، من الضروري تقييم ما إذا كانت الفوائد الطويلة الأجل لبوتين تبرر التكاليف قصيرة الأجل.

اعتبارات حزمة البطارية الذكية

حزم البطارية الذكية ، المدمجة مع الأجهزة الإلكترونية المتقدمة ، تقدم رؤى شاملة وإدارة دقيقة لحالة البطارية. هذه الميزات الذكية لا ترفع أداء البطارية فحسب ، بل تعمل أيضًا على تحسين سلامة المنتج وموثوقيته وتجربة المستخدم.

الوظائف الأساسية لحزم البطارية الذكية

تكمن الوظائف الأساسية لحزم البطارية الذكية في قدرتها على توفير بيانات في الوقت الفعلي عن حالة البطارية ، بما في ذلك على سبيل المثال لا الحصر:

- حالة الشحن (SOC): يشير إلى مستوى شحن البطارية الحالي لمنع الإفراط في الشحن والرسوم الزائدة.

- الإبلاغ عن الخطأ: يوفر إشعارًا في الوقت المناسب للمستخدم حول المشكلات المحتملة مع البطارية ، مثل مخالفات الجهد أو درجات حرارة عالية.

- درجة حرارة التشغيل: تراقب درجة حرارة البطارية لمنع تدهور الأداء أو مخاطر السلامة عن طريق ارتفاع درجة الحرارة.

- وقت التشغيل: يسجل وقت استخدام البطارية ، والمساعدة في التنبؤ بدورات الاستبدال وجداول الصيانة.

- حالة الجهد والجهد: يراقب الإخراج الحالي والجهد للبطارية لضمان تشغيل جهاز مستقر.

تكامل الميزات ذات القيمة المضافة

إلى جانب الوظائف الأساسية ، يمكن لحزم البطارية الذكية دمج الميزات ذات القيمة المضافة لتوسيع نطاق التطبيق الخاص بهم وتعزيز تجربة المستخدم. قد تشمل هذه:

- أجهزة الشحن المدمجة: تمكين الشحن المباشر لحزمة البطارية دون شواحن خارجية ، مما يعزز راحة المستخدم.

- GPIO (إخراج إدخال الغرض العام) خيارات: توفير واجهات للتواصل مع الأجهزة الخارجية ، مما يزيد من تعدد استخدامات حزمة البطارية.

- المراقبة عن بُعد: يتيح للمستخدمين الوصول عن بُعد وإدارة حالة البطارية عن طريق الاتصالات اللاسلكية أو السلكية.

- الشحن اللاسلكي: يلغي الحاجة إلى الأسلاك ، ويقدم تجربة مستخدم أكثر مرونة.

- موازنة الخلية: يضمن أن كل خلية في حزمة البطارية تتقاضى وتصريفات بنفس المعدل ، مما يطيل عمر البطارية.

- بروتوكولات الاتصال: تمكين حزمة البطارية لتبادل البيانات مع أنظمة أو أجهزة أخرى ، مما يسمح بإدارة الطاقة المتقدمة.

موازنة التصميم والتكلفة

في حين أن دمج الميزات الأكثر ذكاءً يمكن أن يعزز الأداء ورضا المستخدم ، فإنه يمكن أن يؤدي أيضًا إلى زيادة تعقيد التصميم والتكاليف. عند تصميم حزمة بطارية ذكية ، يعد تحقيق التوازن بين ثراء الميزات وكفاءة التكلفة أمرًا بالغ الأهمية.

غالبًا ما تتطلب الميزات المتقدمة تصميمات دوائر أكثر تعقيدًا ومكونات إضافية ، والتي يمكن أن تؤدي إلى ارتفاع تكاليف.

قبل إضافة أي وظيفة ، قم بإجراء تحليل التكلفة والفوائد للتأكد من أن التكاليف الإضافية يمكن تبريرها من خلال تحسين الأداء أو تجربة المستخدم.

متطلبات شهادة البطارية

تعد شهادة البطارية ، خاصة بالنسبة للبطاريات المستندة إلى الليثيوم ، خطوة مهمة في امتثال المنتج ، مما يضمن سلامة البطارية في ظل ظروف الاستخدام والنقل المختلفة.

نظرة عامة على عملية إصدار الشهادات

- المتطلبات التنظيمية: الهيئات التنظيمية الدولية مثل الأمم المتحدة/وزارة النقل (UN/DOT) ، شهادة السلامة لبطاريات الليثيوم ..

- الاختبار والتكاليف: تتضمن عملية إصدار الشهادات إرسال عينات من البطارية إلى وكالات الاختبار لمجموعة من الاختبارات ، بما في ذلك اختبارات الإفراط في التفريغ ، والتفريغ الزائد ، ودائرة القصيرة ، واختبارات درجات الحرارة القصوى ، وكلها تتحمل تكاليف إضافية.

استراتيجيات التحكم في تكاليف الشهادة

- تقييم احتياجات الشهادات: في المراحل الأولية لتصميم المنتج ، قم بتقييم ضرورة إصدار الشهادة لتجنب تكاليف الشهادات غير الضرورية.

- استكشاف الحلول البديلة: فكر في استخدام كيمياء البطارية التي لا تتطلب شهادة ، مثل القلوية أو النيكل-الكادميوم أو هيدريد النيكل المعدني ، لتقليل أو إلغاء تكاليف التصديق.

اعتبارات خاصة بالصناعة

قد يكون لدى الصناعات مثل الطبية والطيران والجيش متطلبات اختبار وتوثيق إضافية ، حتى بالنسبة لبطاريات غير ليثوم ، مما قد يؤدي إلى تكاليف إضافية.

خاتمة

في تطوير حزمة بطارية مخصصة ، تحتاج إلى النظر في التكوين الكيميائي ، والخصائص الفيزيائية ، والسلامة ، وفعالية التكلفة.

تعاون وثيق مع ذوي الخبرة مصنعي البطارية المخصص يمكن أن يضمن القرارات الحكيمة خلال عملية التصميم والإنتاج ، وتحقيق التوازن الأمثل بين الأداء والتكلفة. لا تعزز هذه الاستراتيجية القدرة التنافسية في السوق للمنتج فحسب ، بل تضمن أيضًا جودة المنتج وموثوقيته ، مما يوفر قيمة حقيقية للمستخدم النهائي.

مقالات ذات صلة: