À retenir :

- Sélectionnez la bonne technique de charge pour votre batterie afin de maximiser l’efficacité, minimiser les dommages et prolonger sa durée de vie. De la tension constante à la charge aléatoire, chaque méthode a un impact différent sur la santé de la batterie.

Les méthodes de chargement de la batterie affectent les performances et durée de vie. Un courant excessif empêche les réactions complètes, augmentant la résistance et la température, endommageant les matériaux. Un faible courant allonge le temps de charge, ce qui gêne les utilisateurs. Choisir la bonne méthode de chargement est crucial pour maximiser les performances sans avoir à charger longtemps.

Dans ce guide, nous explorerons 9 types courants de charge de batterie – de la charge à tension constante à la charge aléatoire.

Charge à tension constante

La méthode de charge à tension constante utilise une source de tension fixe pour charger les batteries. Ses avantages incluent une structure de circuit simple et une conception de circuit de contrôle facile.

Dans ce mode, le courant de charge diminue à mesure que la batterie approche de sa pleine charge. Une fois complètement chargé, le chargeur passe automatiquement en charge flottante, maintenant ainsi la pleine charge de la batterie.

Cependant, cette méthode présente un inconvénient. Lors des premières phases de charge, la faible tension aux bornes de la batterie entraîne un courant de charge initial trop élevé. Cela peut endommager les plaques de batterie, augmenter la température de la batterie et réduire sa durée de vie.

Pour résoudre ce problème, une méthode de charge en tension à plusieurs étages peut être utilisée. Cette approche utilise initialement une tension de charge plus faible, puis l'augmente à mesure que la tension aux bornes de la batterie augmente.

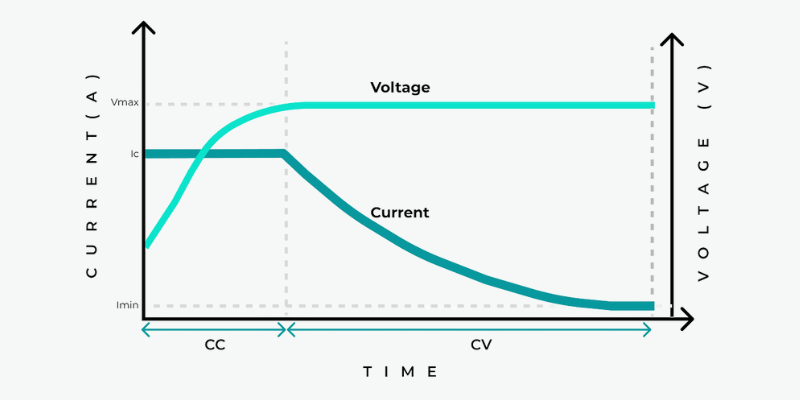

Charge à courant constant

La méthode de charge à courant constant charge la batterie avec un courant constant.

Comme pour la méthode à tension constante, lorsque la batterie est complètement chargée, le chargeur doit passer en mode de charge flottante pour éviter les dommages dus à une surcharge.

Par rapport à la charge à tension constante, cette méthode permet de charger complètement la batterie rapidement.

Il doit cependant surveiller chargement de la batterie niveau de près. Étant donné que le chargeur fournit en permanence un courant constant, le fait de ne pas arrêter la charge ou de passer en mode d'entretien lorsque la batterie est pleine entraînera une surcharge. Cela pourrait endommager les plaques de batterie et réduire la durée de vie de la batterie.

Charge de courant conique

La charge à courant conique est un processus dans lequel le courant de charge diminue progressivement à mesure que la tension de la cellule, ou force contre-électromotrice (contre-électromotrice), augmente. Cette méthode utilise une source d’alimentation non régulée, où la tension et le courant ne sont pas finement contrôlés.

Au fur et à mesure que la batterie se charge, sa résistance interne diminue, permettant à davantage de courant de circuler jusqu'à ce que la batterie atteigne sa pleine charge.

Cependant, une tarification non réglementée présente des risques, notamment une surcharge. Cela peut entraîner une chaleur excessive, des gaz et des dommages à la batterie, réduisant ainsi la durée de vie et créant des risques pour la sécurité s'il n'est pas soigneusement géré.

La charge à courant conique convient uniquement aux batteries SLA.

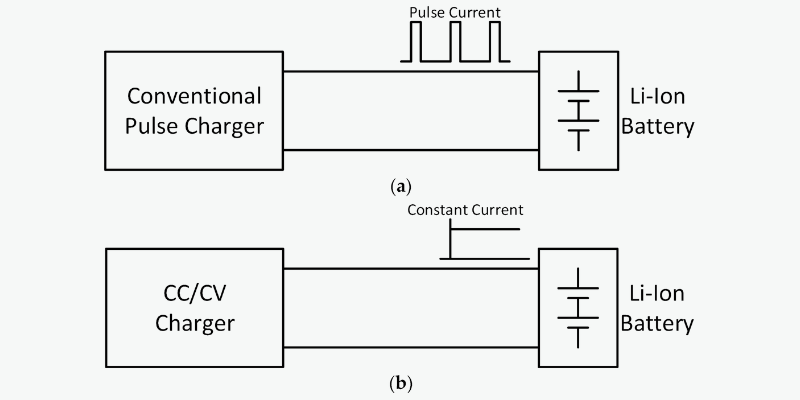

Charge pulsée

La charge par impulsions utilise un courant d'impulsion périodique pour charger les batteries. Les pauses de charge permettent à l'électrolyte de se diffuser plus uniformément, améliorant ainsi l'efficacité. Cela permet à l’énergie de charge d’être entièrement convertie en énergie électrique, ce qui entraîne une efficacité de charge plus élevée.

Chargement du rot

La charge réflexe ou par impulsion négative, également appelée « charge par rot », est une méthode qui applique une impulsion de décharge très courte pendant une période de repos de charge pour dépolariser la cellule.

Cette impulsion, généralement 2 à 3 fois le courant de charge pendant 5 ms, vise à déloger les bulles de gaz accumulées sur les électrodes lors d'une charge rapide.

Ce processus, connu sous le nom de « rots », accélère la stabilisation et le processus de charge global. Les partisans affirment que cette technique améliore les taux de charge, la durée de vie de la batterie et élimine les dendrites. Ces affirmations restent cependant controversées.

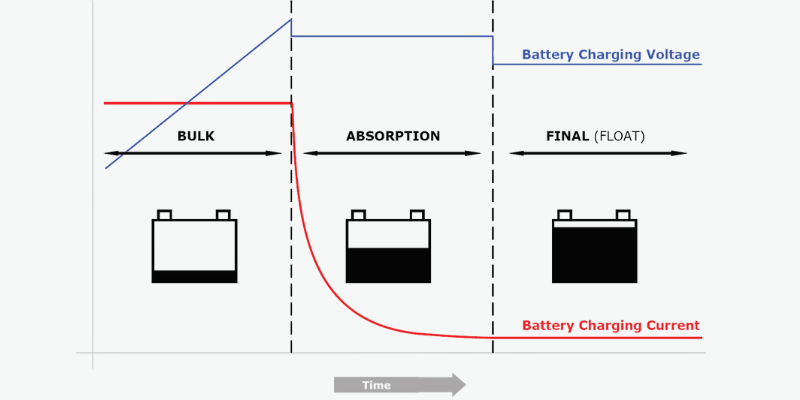

Chargement de l'IIU

Il s'agit d'un profil de charge rapide pour certaines batteries au plomb inondées, qui ne convient pas à toutes les batteries au plomb.

Il comporte trois phases :

1. Charge à courant constant (I) jusqu'à ce que la tension atteigne un niveau prédéfini près du point de gazage (charge globale).

2. Charge à tension constante (U) avec un courant décroissant progressivement, complétant la charge normale.

3. Charge à courant constant (I) jusqu'à une limite prédéfinie plus élevée, égalisant les charges des cellules pour maximiser la durée de vie de la batterie.

Chargement d'entretien

La charge d'entretien maintient une batterie complètement chargée en faisant correspondre son taux d'autodécharge.

Cela se produit lorsque la batterie n'est pas utilisée, car la charge d'entretien ne peut pas maintenir une batterie chargée si du courant est consommé.

Dans les batteries au plomb en charge flottante à vide, la charge d’entretien se produit naturellement à la fin de la charge, lorsque la résistance interne de la batterie augmente et réduit le courant de charge à un niveau d’entretien. Cela équivaut à l’énergie perdue par la batterie en divisant l’eau dans l’électrolyte.

D’autres types de batteries, comme le lithium-ion, ne peuvent pas être chargés en toute sécurité.

Chargement flottant

La charge flottante maintient la charge d’une batterie en appliquant une tension et un courant continus et minimaux pour la maintenir complètement ou presque complètement chargée.

Il est couramment utilisé pour l’alimentation de secours et de secours lorsque la batterie est rarement déchargée.

Pendant la charge flottante, le chargeur, la batterie et la charge sont connectés en parallèle. Le chargeur alimente la charge pendant le fonctionnement normal, la batterie fournissant une alimentation de secours en cas de panne de l'alimentation principale.

Chargement aléatoire

De nombreuses applications impliquent une charge incontrôlée de la batterie, comme dans le cas des utilisations automobiles où l'énergie dépend du régime moteur.

Ceci est particulièrement problématique pour les véhicules électriques et hybrides équipés du freinage par récupération, qui génère des surtensions que la batterie doit absorber.

Les installations de panneaux solaires ne se chargent également que lorsque le soleil brille. Ces applications nécessitent des techniques pour limiter le courant ou la tension de charge à des niveaux de batterie sûrs.

Conclusion

La sélection de la méthode de chargement de la batterie appropriée est essentielle pour optimiser les performances et prolonger la durée de vie de la batterie. Chaque technique de chargement offre des avantages et des défis uniques. En comprenant ces méthodes et leurs implications, nous pouvons garantir des pratiques de charge de batterie sûres et efficaces.

En tant que fournisseur de batterie au lithium personnalisé, Holo Battery propose des services de recharge en interne. Nous disposons d’équipements standards et pouvons créer des solutions de recharge personnalisées pour répondre à toutes les exigences. Cela nous permet de fournir des packs de batteries rechargeables entièrement chargés selon les spécifications du client, prêts à être utilisés immédiatement dans les produits finaux.