Après avoir terminé plus de 6 000 Projets de batterie au lithium personnalisés, nous avons constaté que les clients ont souvent des questions spécifiques. Dans cet article, nous nous plongerons dans les questions et réponses essentielles concernant le Conception et production de batteries au lithium-ion.

Quels sont les facteurs clés à considérer lors du choix d'une batterie lithium-ion personnalisée?

Lors de la sélection d'une batterie lithium-ion personnalisée, il est essentiel de considérer plusieurs facteurs clés.

Premièrement, densité énergétique joue un rôle vital, car les clients recherchent souvent des batteries lithium-ion pour les applications portables, désireux de capacité énergétique élevée dans une conception compacte et légère.

De plus, les taux de sortie doivent être pris en compte. Il existe deux principaux types de cellules lithium-ion – cellules d'énergie et cellules électriques. Les cellules d'énergie offrent une densité d'énergie élevée mais une livraison de courant plus faible, ce qui entraîne un temps d'exécution plus long, tandis que les cellules électriques offrent une puissance à courant élevé rapide avec une densité d'énergie plus faible.

La vie du cycle est un autre aspect essentiel à considérer. Les cellules de phosphate de lithium-ion, bien que potentiellement plus lourdes, peuvent fournir plus de 3 000 cycles, dépassant les cycles 500-600 d'autres types.

La sécurité est primordiale pour toutes les batteries lithium-ion, avec des cellules de phosphate de lithium-ion connues pour leur robustesse améliorée en termes de caractéristiques de sécurité.

De plus, la tolérance à la température est une considération importante. Bien que les batteries au lithium soient auparavant limitées dans des applications à haute température, les progrès permettent désormais leur utilisation dans divers contextes avec des températures élevées.

Comment intégrer la gestion thermique dans un pack de lithium personnalisé?

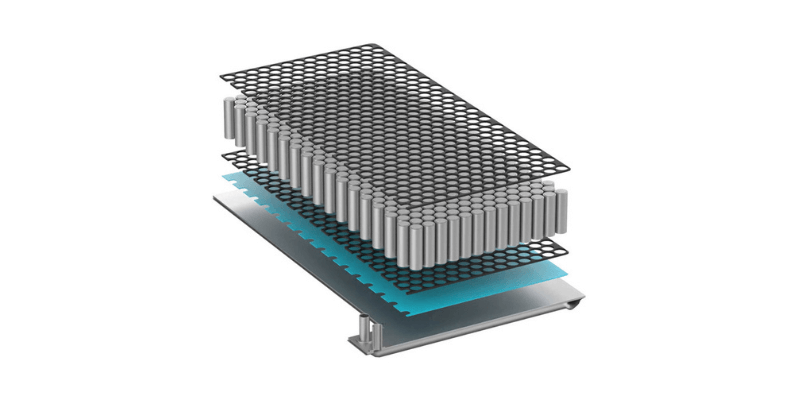

Une enceinte plus grande dissipe souvent mieux la chaleur, et nous ajoutons parfois des épandeurs de chaleur dans les paquets pour gérer l'excès de chaleur.

L'approche de Tesla pour le refroidissement actif établit une norme élevée dans l'industrie, en utilisant la circulation liquide autour des cellules individuelles pour maintenir des températures uniformes et éliminer les gradients thermiques. Ce système avancé garantit que les cellules internes correspondent à la température des cellules externes, permettant même de préchauffer les jours froids pour une efficacité et une longévité améliorées.

Si les contraintes budgétaires limitent les options de refroidissement, en tirant parti des capteurs de température peut être une solution rentable. Ces capteurs peuvent surveiller les variations de température et ajuster le fonctionnement de l'appareil en conséquence, tels que la limitation du processeur ou le réglage de la vitesse du moteur pour éviter la surchauffe.

De plus, la mise en œuvre de systèmes d'avertissement dans la batterie peut aider à alerter les utilisateurs des problèmes de température potentiels et prendre efficacement les mesures préventives.

Quelles fonctionnalités de sécurité moins courantes devraient être incluses dans une batterie de lithium personnalisée?

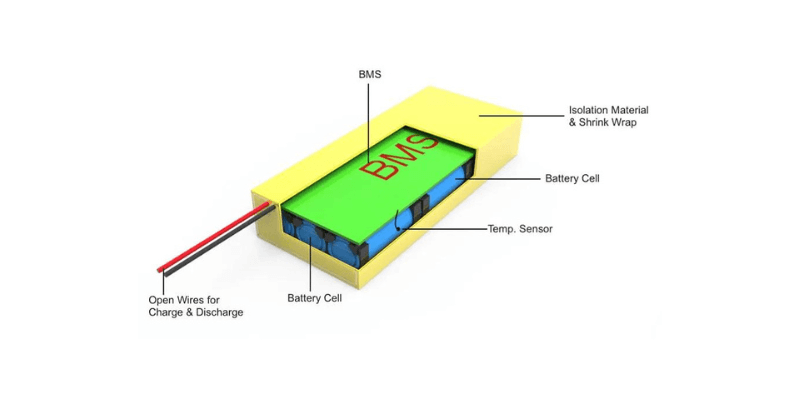

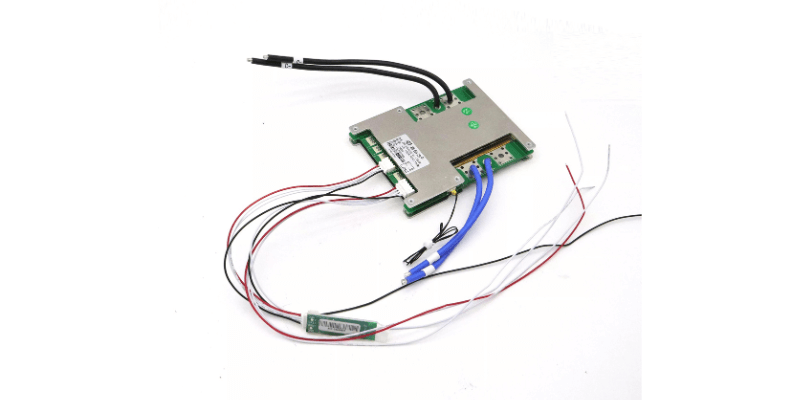

Les caractéristiques de sécurité de deuxième niveau et de troisième niveau passent souvent inaperçues, mais un aspect important est équilibrage cellulaire.

Beaucoup de gens le voient comme une caractéristique de durée de vie du cycle, similaire à remplir uniformément un plateau de glaçons pour garantir que toutes les cellules maintiennent des niveaux égaux. Cet équilibre prolonge la durée de vie du pack et empêche les cellules individuelles de tomber trop bas ou de hausse trop élevée, ce qui peut déclencher des circuits de sécurité et réduire la perception de l'exécution.

De plus, si les circuits de sécurité sont un dysfonctionnement, des excursions continues ou élevées peuvent entraîner une croissance de la dendrite ou des problèmes avec des matériaux de séparation, provoquant potentiellement des shorts internes. Ainsi, l'équilibrage des cellules est en effet une caractéristique de sécurité.

D'autres considérations incluent les batteries encapsulantes avec des vannes de décharge de pression efficaces. Il peut aider à atténuer le risque de surpression dans la batterie, en particulier pendant la charge rapide ou en cas de dysfonctionnement.

Enfin, l'utilisation de matériaux ignifuges évalués pour des températures élevées garantit que composants Ne vous allumez pas pendant les situations de défaillance. Ces caractéristiques de sécurité moins connues jouent un rôle crucial dans les performances et la fiabilité de la batterie.

La plupart des normes du produit final nécessitent-elles des batteries pour répondre aux normes spécifiques?

Oui, la plupart des normes de produit final exigent que les batteries répondent à des critères spécifiques de sécurité, de performance et de qualité pour garantir la sécurité des consommateurs et la fiabilité des produits. Les organismes de réglementation imposent ces normes pour atténuer les risques comme les risques d'incendie, emballement thermiqueet impact environnemental.

Les normes clés comprennent:

- ET 38.3: Couvre les exigences de test pour le transport sûr des batteries au lithium.

- CEI 62133: Spécifie les exigences de sécurité pour les batteries au lithium dans des dispositifs électroniques portables.

- CEI 62619: se concentre sur la sécurité des cellules et batteries lithium-ion secondaires dans les applications industrielles.

- UL1642 et UL 2054: Normes de sécurité pour les batteries au lithium à usage domestique et industriel.

- Marque CE: indique une conformité avec les normes de sécurité de l'UE.

La conformité est nécessaire pour empêcher les rappels, les passifs légaux et les dommages à la réputation de la marque; Les fabricants doivent respecter ces normes pour fournir des produits sûrs à batterie.

Avez-vous des recommandations pour trouver des cellules en ligne pour la fabrication interne? Est-ce aussi simple que d'utiliser Google pour trouver des options qui répondent à mes exigences?

Bien que Google puisse être un point de départ, voici des recommandations pour trouver des fournisseurs de cellules fiables:

- Associer à fournisseurs réputés connus pour les cellules de batterie de qualité et un support fiable.

- Confirmer des spécifications claires, y compris la tension, la capacité, la densité d'énergie, cycle de vie, Taille, poids et fonctionnalités de sécurité pour réduire votre recherche.

- Assurer la compatibilité avec votre système en considérant l'ajustement mécanique, les connexions électriques et les protocoles de charge / décharge pour éviter les problèmes d'intégration pendant la fabrication.

- Choisissez des cellules qui répondent aux normes de l'industrie reconnues comme UL ou IEC pour la sécurité et les performances; Passez en revue les lieux techniques de produits ou les rapports de test du fournisseur.

- Consulter les experts de l'industrie, les ingénieurs ou les consultants expérimentés dans l'approvisionnement en cellules de batterie pour la fabrication. Ils peuvent vous guider dans la sélection des bonnes cellules pour vos besoins spécifiques.

- Évaluez la logistique d'expédition concernant les options, les délais de direction, les coûts et les exigences de livraison.

Comment déterminez-vous la durée de vie du cycle d'un produit?

Généralement, la détermination de la durée de vie du cycle d'une batterie implique plusieurs méthodes:

- Spécifications du fabricant: Vérifiez la durée de vie du cycle estimé du fabricant, qui est souvent basée sur des tests standardisés. Cependant, ces valeurs reflètent généralement des courants à l'état d'équilibre faibles.

- Tests de vieillissement accéléré: effectuer des tests dans des conditions contrôlées en chargeant et en décharge à plusieurs reprises la batterie tout en surveillant les performances et la baisse de la capacité. Cette méthode estime le nombre de cycles que la batterie peut supporter avant d'atteindre un seuil de capacité spécifique (par exemple, 80% de la capacité d'origine).

- Données et expérience passées: les données historiques sur des batteries similaires peuvent fournir un aperçu de la durée de vie du cycle attendu grâce à la recherche et aux études de cas, bien que cette méthode offre des estimations approximatives.

- Chimie et conception de la batterie: Différentes chimies ont des caractéristiques de durée de vie du cycle variable; les comprendre ainsi que des facteurs de conception comme électrode Les matériaux peuvent donner des estimations approximatives des performances.

- Conditions opérationnelles: des facteurs tels que le taux de décharge, la profondeur de libération (DoD), les protocoles de charge et les conditions environnementales influencent considérablement la durée de vie du cycle.

Bien que ces méthodes fournissent des estimations approximatives, les tests réels adaptés à des conditions spécifiques sont le moyen le plus fiable de déterminer la durée de vie du cycle d'une batterie, en particulier pour les produits extérieurs soumis à des températures extrêmes.