Di Holo Battery, kami telah membuat kerajinan paket baterai khusus selama lebih dari 18 tahun. Kami memahami bahwa mengembangkan solusi ketenagalistrikan baru menimbulkan pertanyaan penting mengenai kinerja dan keselamatan. Itu sebabnya kami membuat FAQ ini untuk menjawab pertanyaan umum dari para insinyur dan manajer proyek, membantu Anda dalam perjalanan paket baterai khusus Anda.

Desain Inti dan Pemilihan Komponen

Pertanyaan: Bagaimana Anda mengetahui jenis sel yang harus dipilih untuk proyek Anda?

Pemilihan sel adalah dasar kinerja baterai Anda. Pilihannya bergantung pada keseimbangan yang cermat antara persyaratan utama aplikasi Anda:

- Kepadatan Energi (Wh/kg) vs. Kepadatan Daya (W/kg): Apakah perangkat Anda memerlukan waktu pengoperasian yang lama (misalnya, UAV, perangkat medis) atau semburan daya yang tinggi (misalnya, perkakas listrik, robotika)? Sel Lithium Nikel Mangan Cobalt (NMC) menyediakan lebih tinggi kepadatan energi, sedangkan Litium Besi Fosfat (LiFePO4) unggul dalam siklus hidup.

- Siklus Hidup: Berapa banyak siklus pengisian/pengosongan yang diperlukan? LiFePO4 memberikan siklus hidup terpanjang, ideal untuk penyimpanan tenaga surya dan keperluan industri.

- Lingkungan Pengoperasian: Akankah baterai menghadapi suhu ekstrem? Beberapa kimia, seperti baterai natrium-ion, lebih baik untuk kondisi dingin.

- Profil Keselamatan: Pertimbangkan risiko keselamatan; LiFePO4 dikenal dengan stabilitas termalnya.

Tentukan kapasitas dan voltase yang dibutuhkan perangkat Anda, termasuk penarikan arus. Sel yang berbeda memiliki kapasitas dan laju pelepasan yang berbeda-beda, jadi pertimbangkan faktor bentuk sel untuk memenuhi batasan dimensi. Insinyur Baterai Holo menganalisis faktor-faktor ini untuk merekomendasikan sel Kelas A dari pemasok terkemuka yang selaras dengan sasaran biaya dan kinerja proyek Anda.

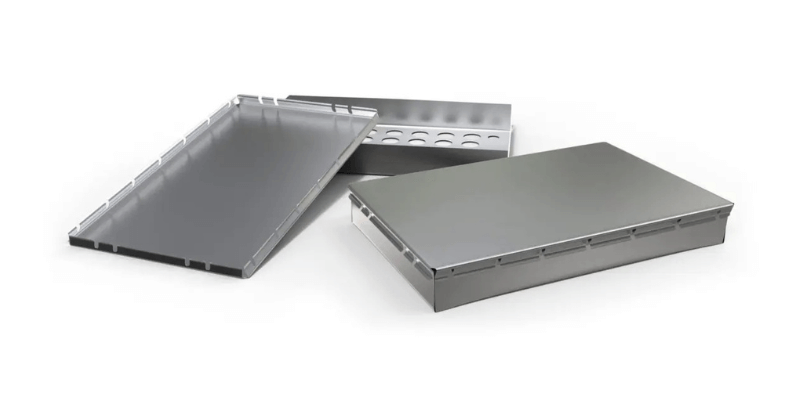

Pertanyaan: Bagaimana Anda menentukan jenis bahan apa yang dibutuhkan untuk sebuah selungkup?

Saat memilih bahan penutup yang tepat, kami mempertimbangkan faktor-faktor seperti kebutuhan Peringkat IP, kapasitas berat, manajemen panas, dan kepatuhan terhadap peraturan (seperti sifat mudah terbakar UL94).

Jika Anda membutuhkan pilihan yang ringan dan terjangkau dengan ketahanan benturan yang baik dan bentuk khusus, plastik seperti ABS dan PC adalah pilihan yang sangat baik.

Namun, untuk perlindungan EMI berkekuatan tinggi, efektif, dan manajemen panas di lingkungan yang menuntut seperti lingkungan industri atau militer, logam seperti aluminium dan baja adalah pilihan yang ideal.

Kami siap membantu Anda memilih bahan terbaik untuk memastikan sel Anda aman, mengelola panas secara efektif, dan berintegrasi secara sempurna dengan desain produk Anda.

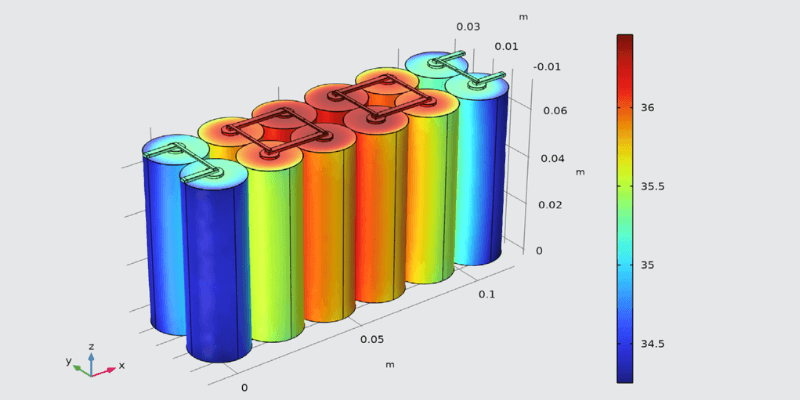

Pertanyaan: Bagaimana Anda berencana mengendalikan termal di dalam wadah baterai?

Efektif manajemen termal tidak dapat dinegosiasikan demi keamanan dan umur panjang. Manajemen panas yang buruk mengakibatkan kinerja yang lebih buruk, keausan yang lebih cepat, dan potensi masalah keselamatan. Inilah cara kami mengatasinya:

- Pendinginan Pasif: Kami menggunakan bahan konduktif termal seperti casing aluminium dan bantalan antarmuka termal yang secara alami menghilangkan panas, ideal untuk kebutuhan daya sedang.

- Pendinginan Aktif: Untuk situasi berdaya tinggi, seperti powertrain EV atau penyimpanan energi tingkat lanjut, kami menggunakan kipas atau pendingin cair untuk mengelola panas berlebih.

- Integrasi BMS: Kebiasaan kami Sistem Manajemen Baterai memonitor suhu sel secara real-time. Jika terjadi panas berlebih, mereka dapat mengurangi tingkat pengisian/pengosongan atau mematikan sistem untuk memastikan keamanan.

Peran Sistem Manajemen Baterai (BMS)

Pertanyaan: Apakah semua paket baterai memerlukan BMS untuk mengontrol pengisian dan pengosongan?

Tidak semua paket baterai memerlukan BMS, tetapi paket lithium-ion memerlukannya. BMS sangat penting untuk:

- Keamanan: Melindungi terhadap pengisian berlebih, pengosongan berlebih, arus berlebih, dan korsleting.

- Pertunjukan & Umur Panjang: Menyeimbangkan sel untuk memastikan keausan merata dan memaksimalkan siklus hidup.

- Pemantauan: Menyediakan data tentang Status Pengisian Daya (SoC), Status Kesehatan (SoH), dan parameter lainnya melalui protokol seperti CANBus atau Bluetooth.

Pertanyaan: Bagaimana cara menentukan kapan baterai harus diisi jika tidak digunakan atau sudah disimpan dalam jangka panjang?

Baterai litium-ion memiliki tingkat pengosongan otomatis yang rendah, namun protokol khusus diperlukan untuk penyimpanan jangka panjang.

Kami merekomendasikan untuk menyimpan baterai dengan SoC 30-50% di tempat sejuk dan kering. Untuk inventaris atau penggunaan musiman, BMS pintar hadir dengan daya rendah “tidur” mode tetapi secara berkala memeriksa voltase. Jika voltase turun di bawah ambang batas aman, pengguna akan diberitahu untuk melakukan pengisian daya pemeliharaan.

Pertanyaan: Dapatkah sekering yang dapat disetel ulang digunakan dalam kemasan?

Sekering yang dapat disetel ulang, atau PPTC, tidak baik untuk perlindungan utama pada paket baterai berperforma tinggi. Mereka memiliki resistensi yang lebih tinggi dan dapat tersandung karena perubahan suhu, bukan hanya karena arus berlebih.

Oleh karena itu, kami lebih memilih menggunakan saklar solid-state khusus di BMS, bersama dengan sekering biasa untuk kegagalan besar yang jarang terjadi. Pendekatan ini memungkinkan kita membangun pengaturan keselamatan yang solid dan berlapis-lapis.

Sertifikasi, Perlindungan, dan Biaya

Pertanyaan: Apakah pelindung EMI/RFI diperlukan untuk kemasan baterai?

Untuk paket dasar yang hanya berisi sel dan perlindungan dasar, Anda biasanya tidak perlu khawatir tentang pelindung EMI/RFI.

Namun, untuk paket pintar dengan fitur seperti BMS, sistem komunikasi, konverter DC-DC, atau arus switching tinggi, pelindung mungkin diperlukan.

Hal ini sangat bergantung pada peraturan dan sensitivitas perangkat yang Anda gunakan.

Pertanyaan: Dapatkah Baterai Holo membantu mensertifikasi paket baterai untuk pelanggan?

Tentu saja. Sebagai produsen bersertifikasi ISO, kami memiliki pengalaman luas dalam membantu klien menavigasi proses sertifikasi. Kami dapat mengelola dan mengamankan semua sertifikasi internasional utama untuk baterai Anda, termasuk namun tidak terbatas pada:

- UL 2054 / UL 2580 (Amerika Utara)

- IEC 62133 (Internasional)

- EC (Eropa)

- UN38.3(Transportasi)

Dengan menggunakan sel pra-sertifikasi dan komponen, kami memastikan produk Anda mencapai pasar dengan cepat dan patuh!

Pertanyaan: Berapa biaya pengembangan, termasuk sertifikasi baterai?

Biaya dapat sangat bervariasi berdasarkan kompleksitas proyek, jumlah pekerjaan yang diperlukan, dan sertifikasi yang diperlukan. Faktor utama yang mempengaruhi biaya meliputi:

- Rekayasa Kustom: Kompleksitas BMS, desain mekanis, dan manajemen termal.

- Prototyping: Jumlah unit prototipe yang diperlukan untuk pengujian.

- Sertifikasi: Standar dan wilayah spesifik yang Anda targetkan.

- Perkakas: Biaya untuk cetakan atau perlengkapan khusus untuk produksi skala besar.

Di Holo Battery, kami percaya pada transparansi. Janji penawaran harga cepat kami memberikan perkiraan awal yang jelas. Kami berkolaborasi dengan Anda untuk membuat desain seefektif mungkin, tanpa mengorbankan keselamatan atau kinerja, sehingga memastikan Anda mendapatkan nilai terbaik.

Ada pertanyaan lain? Jangan khawatir! Tim di Holo Battery siap membantu. Hubungi kami hari ini, dan mari ngobrol tentang kebutuhan paket baterai khusus Anda.