Poin Penting:

- Harga baterai litium dipengaruhi oleh berbagai faktor termasuk komposisi sel, sistem manajemen baterai, desain kemasan khusus, dan pengujian/sertifikasi.

- Memahami elemen-elemen ini sangat penting untuk mengelola pengeluaran secara efektif dan mengoptimalkan kinerja baterai.

Ketika individu atau bisnis membeli paket baterai, pengeluaran adalah titik fokus utama.

Pada tahun 2023, rata-rata harga baterai kendaraan listrik pada tahun 2023 adalah $128/kWh. Harga ini jauh lebih rendah dibandingkan harga pada tahun 2008, yaitu $1.355/kWh. Namun, perlu dicatat bahwa baterai litium secara konsisten memiliki biaya kimia baterai yang lebih tinggi.

Harga baterai lithium dipengaruhi oleh berbagai elemen. Ini termasuk sel itu sendiri, itu sistem manajemen baterai (BMS), sistem paket baterai secara keseluruhan, biaya pengujian dan pengiriman.

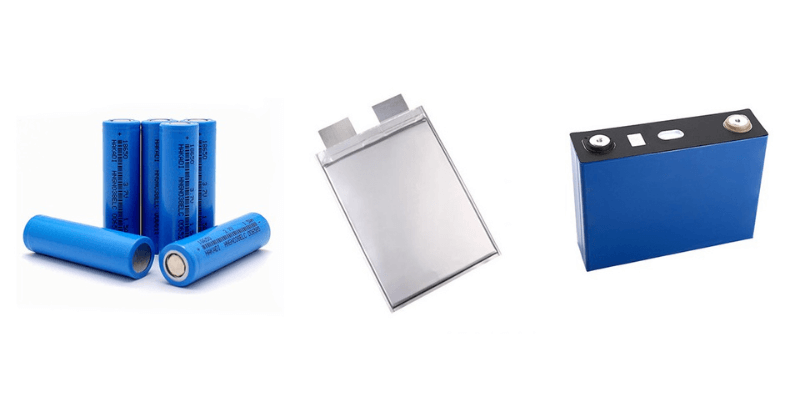

Sel Baterai

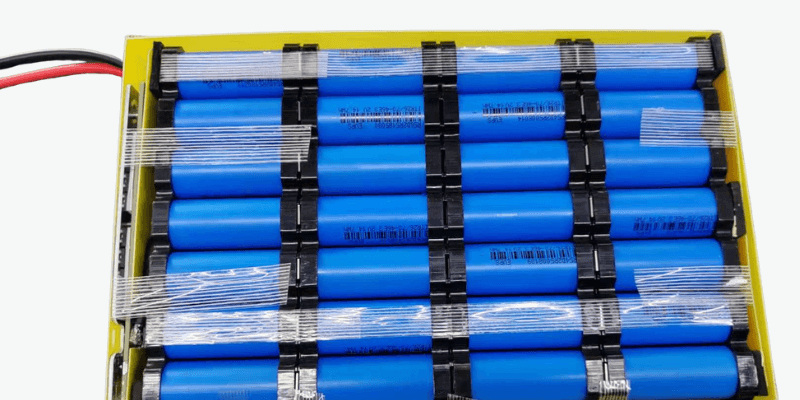

Sel baterai individual mewakili sekitar 80% dari total biaya produksi. Sel baterai terdiri dari beberapa bagian: katoda, anoda, elektrolit, pemisah, dan selubung luar.

Bahan katoda dan proses produksinya cenderung menjadi elemen yang paling mahal, diikuti dengan biaya anoda dan separator.

Katoda terutama terdiri dari litium yang dikombinasikan dengan kobalt, nikel, atau mangan, sedangkan grafit biasanya digunakan untuk anoda. Harga pasar untuk bahan-bahan ini dapat bervariasi berdasarkan pasokan dan permintaan, dan meningkatnya permintaan akan perangkat elektronik dan kendaraan listrik berperforma tinggi telah mengakibatkan kelangkaan logam-logam ini.

Ketersediaan sumber daya global diperkirakan akan berkurang pada tahun 2050. Isu seperti gelombang panas yang berdampak pada pasokan litium di Tiongkok dan kekhawatiran terkait praktik penambangan kobalt di Republik Demokratik Kongo telah mengangkat isu lingkungan hidup dan hak asasi manusia.

Karena kerusuhan politik di wilayah tertentu, produsen di beberapa negara hanya memiliki akses yang dapat diandalkan terhadap bahan-bahan tersebut dalam jumlah besar, sehingga berpotensi menimbulkan gangguan rantai pasokan.

Sebagai akibat dari faktor-faktor yang menaikkan biaya, produsen cenderung menaikkan harga sel sebagai responsnya.

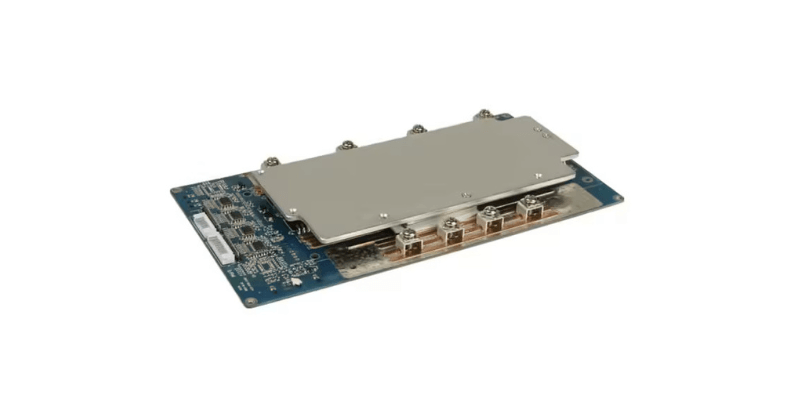

BMS

Mekanisme perlindungan dan pengisian daya baterai litium berdampak signifikan pada biaya produksi paket baterai.

Sejalan dengan peraturan internasional, semua baterai berbasis litium harus dilengkapi dengan BMS. Sistem ini bertugas memantau status pengisian daya (SoC) dan status kesehatan (SoH) baterai, menjaga baterai dari kerusakan, dan memperpanjang masa pakainya dengan mencegah pengisian daya yang berlebihan atau pengosongan yang berlebihan.

Biaya BMS bergantung pada fitur yang dibutuhkan pelanggan pada perangkat mereka. Unit BMS dasar memantau SoC, SoH, dan suhu. Unit tingkat lanjut mungkin mencakup penyeimbangan baterai, jam waktu nyata, pencatat data, dan banyak lagi. Lebih banyak fitur meningkatkan biaya PASI. Pemahaman yang jelas tentang kebutuhan daya sangat penting bagi pelanggan untuk menentukan tingkat fitur yang sesuai untuk disertakan dalam BMS.

Selama proses pengisian daya, sirkuit terintegrasi (IC) di dalam pengisi daya baterai digunakan. Ada berbagai jenis IC yang tersedia, seperti pengisi daya linier dan pengisi daya mode sakelar. IC ini tidak hanya mengisi baterai tetapi juga memberikan perlindungan terhadap tegangan lebih dan arus lebih.

Biaya yang terkait dengan pengisi daya baterai bergantung pada apakah pelanggan lebih memilih pengisi daya yang disertakan dengan baterai untuk segera digunakan atau mengizinkan pengguna akhir untuk memilih pengisi daya mereka sendiri. Pilihan antara pengisi daya khusus dan standar juga memengaruhi biaya, karena pengisi daya khusus biasanya lebih mahal.

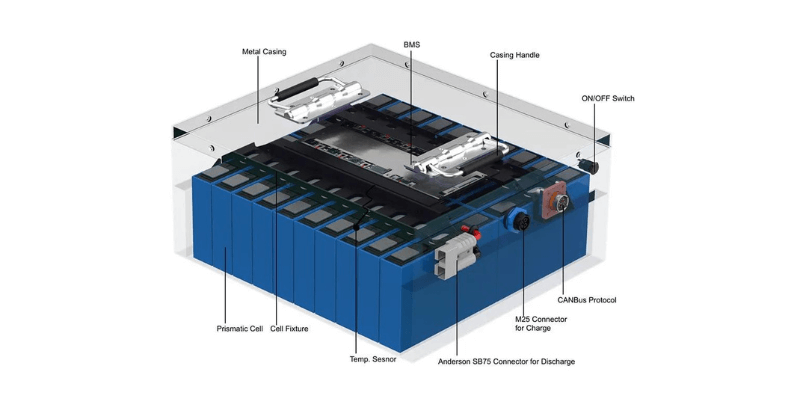

Sistem Paket Baterai Khusus

Sistem paket baterai terdiri dari penutup baterai dan berbagai komponen, termasuk rangkaian kabel, relai, konektor, perangkat lunak BMS, dan sistem manajemen termal untuk pemanasan dan pendinginan. Komponen-komponen ini memastikan pasokan daya baterai litium yang stabil ke berbagai perangkat.

Meskipun rangkaian kabel, konektor, dan BMS merupakan komponen standar, elemen lainnya disesuaikan untuk memenuhi kebutuhan spesifik aplikasi yang berbeda.

Dalam proses merancang sistem paket baterai khusus, penambahan komponen tambahan akan meningkatkan biaya produksi secara proporsional.

Penting juga untuk diperhatikan bahwa mengganti komponen tertentu dengan bahan yang lebih murah (seperti relai) dapat memengaruhi kinerja dan masa pakai baterai secara keseluruhan. Pelanggan harus mempertimbangkan keseimbangan antara desain dan biaya produksi sistem paket baterai serta kinerja dan kualitasnya.

Dalam beberapa kasus, memilih sistem paket baterai berkualitas lebih tinggi, meskipun biaya di muka lebih tinggi, dapat menghasilkan penghematan jangka panjang karena peningkatan daya tahan baterai.

Pengujian Dan Pengiriman

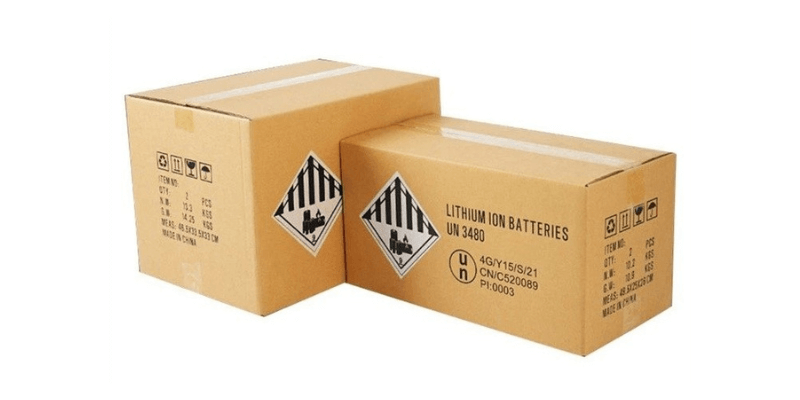

Produsen paket baterai litium harus mensertifikasi paket baterai litium untuk keamanannya sebelum diangkut.

Beberapa sertifikasi, seperti CE, dilakukan sendiri; yang lain memerlukan laboratorium eksternal. Biaya berkisar dari $500 hingga $30.000, tergantung pada jenis sertifikasi. Paket sampel diperlukan untuk pengujian destruktif dan non-destruktif.

Desain ulang mungkin diperlukan jika pengujian gagal, sehingga meningkatkan biaya karena desain baru juga harus disertifikasi. Pergantian produsen, bahkan dengan desain yang sama, mungkin memerlukan pengujian ulang dan sertifikasi ulang. Pelanggan harus selalu menganggarkan anggaran untuk pengujian baterai litium, sertifikasi, dan persyaratan transportasi.

Kesimpulan

Saat ini, biaya desain dan produksi baterai litium lebih tinggi dibandingkan jenis baterai kimia lainnya.

Namun, dengan kemajuan teknologi yang berkelanjutan, produsen secara aktif berupaya membuat komposisi kimia ini lebih hemat biaya tanpa mengurangi daya yang disediakan untuk berbagai perangkat.

Bagi mereka yang ingin menyesuaikan paket baterai dan pengisi daya, memahami kebutuhan daya yang tepat pada aplikasi mereka sangatlah penting. Memberikan dokumentasi yang komprehensif kepada produsen selama tahap desain dapat menghasilkan solusi yang lebih hemat biaya. Melibatkan produsen sejak awal proses desain juga dapat membantu memitigasi tantangan manufaktur dan mengurangi limbah, sehingga pada akhirnya menghasilkan hasil yang lebih hemat biaya.