Per anni, gli OEM hanno considerato la batteria un ripensamento – a commodity component they could plug and play.

That era is over.

In 2026, high-performance robotics and medical tech require energy densities that off-the-shelf units simply cannot provide. They also need to fit into smaller spaces. Standard batteries from a catalog often fail to meet these strict constraints. That is why many engineers are switching to pacchi batteria personalizzati.

Here is why this shift is happening and how it will redefine your product’s performance.

Trend #1: New Types of Chemistry

Lithium supply chain volatility remains a strategic risk. Despite price stabilization, geopolitical threats persist. OEMs are hesitant to rely solely on one chemistry for their product lines.

The strategic alternative is Sodium-Ion.

Industry forecasts project the Sodium-ion battery market to grow from USD 0.67 billion in 2025 to USD 2.01 billion by 2030 (CAGR 24.7%). This isn’t just hype; it is driven by hard technical advantages:

- Resource Abundance: Sodium is globally abundant, insulating OEMs from lithium shortages and price spikes.

- Intrinsic Safety: Superior thermal stability with higher runaway onset temperatures than standard NMC cells.

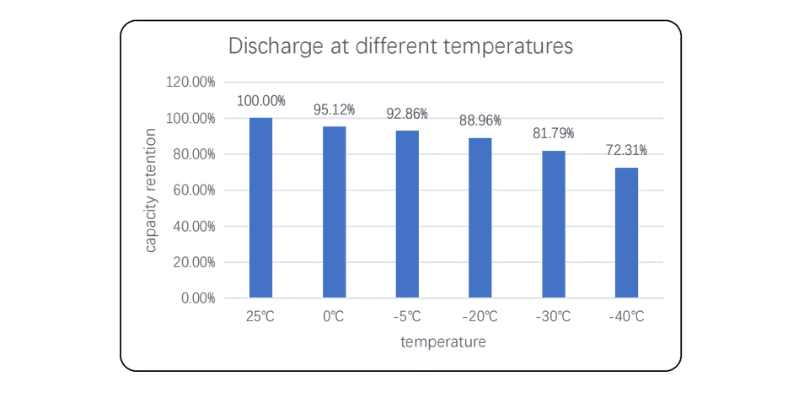

- IL “Arctic” Advantage: Unlike standard Li-ion cells that “sonno” at freezing temps, Sodium-ion battery packs retain nearly 90% capacity at -20°C.

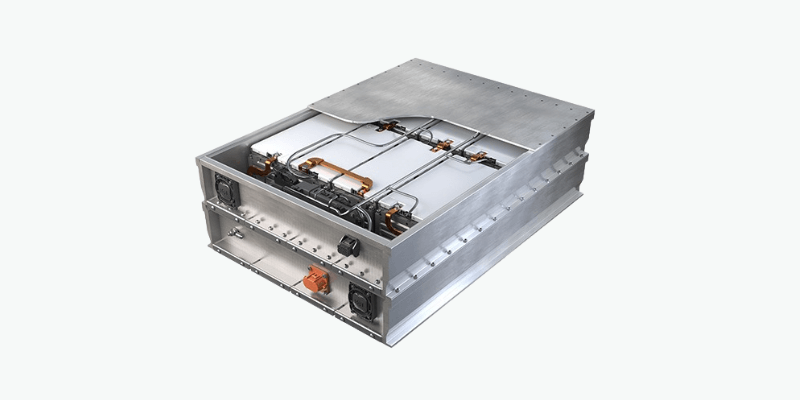

The Holo Battery Approach

At Holo Battery, we execute solutions based on your specific demands.

Since Sodium-ion and Lithium-ion differ in size and energy density, off-the-shelf packs rarely fit. We analyze your application’s operating conditions, space, and power constraints to engineer the exact pack you need – giving you the freedom to choose the right chemistry for your supply chain without compromising on design.

Trend #2: Smarter Batteries

In the past, a standard battery was “dumb” – a simple fuel tank that gave power until it ran empty. The BMS (Sistema di gestione della batteria) was just a safety switch to stop it from catching fire.

In 2026, that is no longer enough.

Modern industrial machines require the battery to be an intelligent node in their IoT network. Engineers now demand batteries that can “talk” to the host device using specific communication standards. This conversation is critical for performance:

- CANBus: Used in mobile robotics (AGVs) to sync with motor controllers in milliseconds. It allows the battery to say, “I am under heavy load, please reduce speed,” preventing sudden shutdowns.

- RS485: The standard for stationary storage, enabling long-distance monitoring for telecom towers.

- Bluetooth (BLE): Allows end-users to check health and charge levels via smartphone without opening the equipment housing.

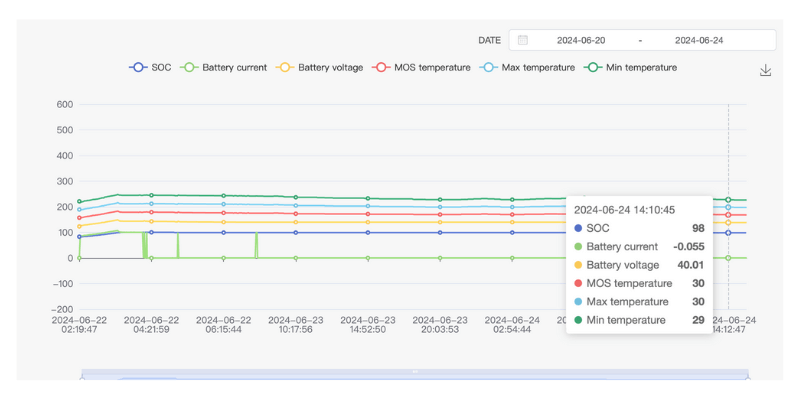

The Holo Battery Edge: Firmware as a Fortress

While hardware is easy to copy, our advantage lies in firmware.

At Holo Battery, we integrate Proprietary State of Health (SoH) algorithms and “Black Box” logging.

Our custom BMS records critical events (over-current spikes, temp extremes) to onboard memory. This data is retrievable during service, helping you distinguish between a battery defect and user misuse – saving thousands in warranty costs.

Trend #3: Form Factor Flexibility

Standard batteries are bricks. Modern devices are not.

Placing a square battery into a curved drone fuselage creates dead space. That is wasted potential.

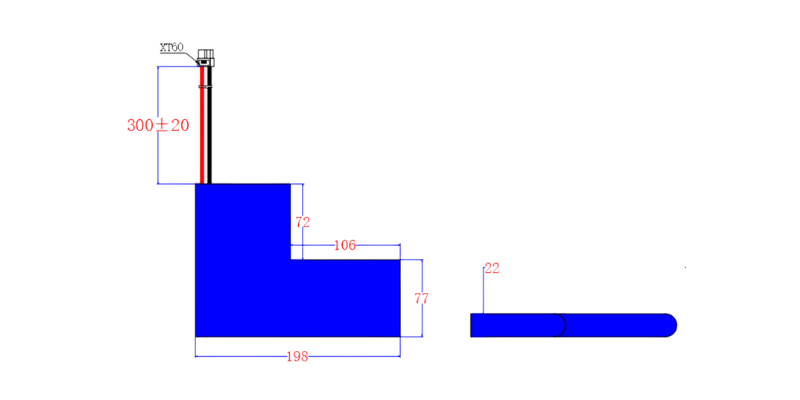

Custom packs solve this. We arrange cells to fit the device, not the other way around. Whether it’s L-shapes, split-packs, or ultra-thin designs, we ensure every inch of space powers your product.

Case Study: The Drone “Endurance” Project

The Challenge: A surveillance drone client was using a standard 6S 22.2V “brick” battery. The bulky shape forced a wider fuselage, creating high drag that capped flight time at 35 minutes.

The Holo Solution: We redesigned the pack to slide inside the streamlined fuselage. We split the battery into two narrower sub-modules connected by a flexible harness, allowing it to hug the drone’s internal curve.

The Results:

- Aerodynamics: Fuselage drag reduced by 15%.

- Capacity: Optimized packing allowed for higher-capacity cells (+22% Energy Density).

- Flight Time: Increased from 35 to 48 minutes.

How Fast Can You Get a Custom Battery Pack?

Many people think custom batteries take too long to design. That used to be true, but it is faster now.

You do not need to wait months to see if a design works.

- The 48-Hour Drawing: Send us your constraints, and we will generate a preliminary 3D GA (General Arrangement) drawing within 48 hours. This isn’t just a sketch; it’s a feasibility check to ensure the pack fits your mechanical housing.

- The 2-4 Week Sample: Once the design is approved, we can deliver a functional prototype in just 2 to 4 weeks.

- IL “Grade A” Guarantee: Speed doesn’t mean cutting corners. We use strictly Grade A cells from Tier-1 manufacturers (such as Samsung, EVE). We test every cell for internal resistance and capacity consistency before assembly.

Is It Worth the Cost?

You might think a custom battery is too expensive. The price for one custom pack is higher than a standard off-the-shelf pack. But standard packs have hidden costs.

If a standard pack does not fit right, your workers spend extra time installing it. If it is not powerful enough, it might fail early. This leads to warranty claims.

A custom pack comes with the right connectors and the right wire lengths. Your team can plug it in instantly. It is built to handle the exact power needs of your machine. This makes it last longer.

Conclusione

In 2026, the battery is the heart of your product.

Treating it as a commodity is a strategic risk. The winners in the next generation of industrial tech will be the OEMs who engineer their power systems as carefully as they design their software.

Don’t let a catalog battery define your product’s limits.

Ready to build something better? Contact Holo Battery today. Send us your requirements or STP/STEP files, and let’s verify your fit with a preliminary 3D drawing in just 48 hours.