小型・高性能の要求 バッテリーパック ウェアラブル技術、医療機器、ドローン、IoT センサーなどの業界全体で急増しています。これらのアプリケーションには、信頼性の高いエネルギーを供給し、物理的ストレスに安全に耐える軽量の電源が必要です。

しかし、性能や安全性を犠牲にすることなくバッテリーのサイズを縮小することは、エンジニアリング上の大きな課題となります。この記事では、これらの課題を検討し、それらに対処するための戦略を提供します。

コンパクトバッテリーパックとは何ですか?

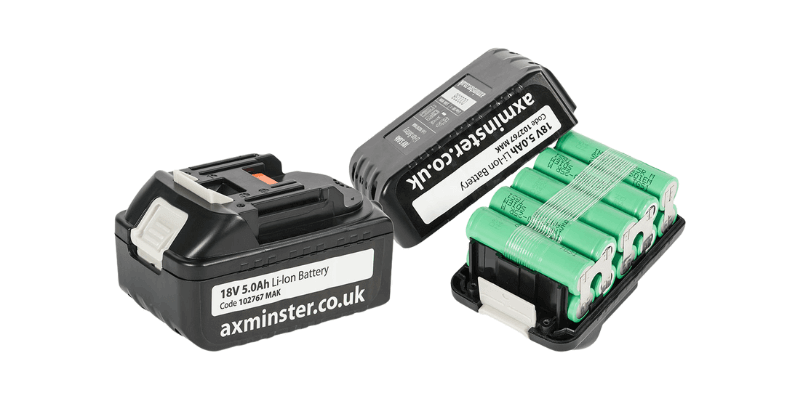

コンパクトなバッテリー パックは、電力を犠牲にすることなく、スペースに制約のあるデバイス向けに設計されたカスタム エネルギー貯蔵システムです。標準的なバッテリーとは異なり、これらのパックは特定のサイズ、重量、および性能要件を満たしています。多くの場合、最小限のスペースで最大の容量を得るために、高度なリチウムイオン (Li-ion) またはリチウムポリマー (LiPo) セルが使用されます。

たとえば、補聴器にはコインサイズのリチウムイオンパックが使用され、ドローンにはスリムな LiPo 構成が使用される可能性があります。その設計は、効率、耐久性、さまざまな環境への適応性を優先しています。

小型バッテリーに共通する設計上の課題

バッテリーパックを設計する際には、性能、構造的完全性、安全性という 3 つの重要な要素が不可欠です。これらの側面は、サイズが小さく材料が限られているため、コンパクトなバッテリーパックにとって課題となっています。

パフォーマンス

主な課題はバランスを取ることです エネルギー密度 電力供給付き。バッテリーが小さいと蓄えるエネルギーが少なくなり、稼働時間が制限されます。ドローンや電動工具の放電率が高いと、過熱や電圧降下が発生し、効率が低下する可能性があります。

エンジニアは次のことも考慮する必要があります サイクル寿命頻繁に充電と放電を行うと、狭い間隔と熱ストレスにより小型バッテリーがより早く劣化する可能性があるためです。

構造的完全性

コンパクトな設計では、機械的な堅牢性が犠牲になることがよくあります。薄いケースやフレキシブル PCB は、振動、衝撃、または温度変化によって曲がったり、亀裂が入ったりする可能性があります。

ウェアラブルでは、屈曲を繰り返すと内部接続が弱くなる可能性があります。設計者は、デバイスがかさばらずに物理的ストレスに耐えられるようにする必要があります。

安全性

コンパクトな設計では安全上のリスクが増加します。間隔が狭いと熱暴走が発生する可能性があり、1 つのセルが過熱すると連鎖反応が引き起こされます。

リチウム電池は管理を誤ると、膨張、液漏れ、発火する可能性があります。などの厳しい安全基準 そして38.3、短絡、過充電、極端な温度に対する厳格なテストが義務付けられています。

コンパクトなバッテリー設計の課題を克服する

ここでは、コンパクトなバッテリー設計の課題を克服するためのヒントを紹介します。

バッテリーセルの容量と電圧の増加

- 高度な化学: シリコンアノードのリチウムイオン電池を使用すると、グラファイトアノードよりも 20 ~ 30% 高い容量が得られます。新しい全固体電池は、さらに優れたエネルギー密度と安定性を提供します。

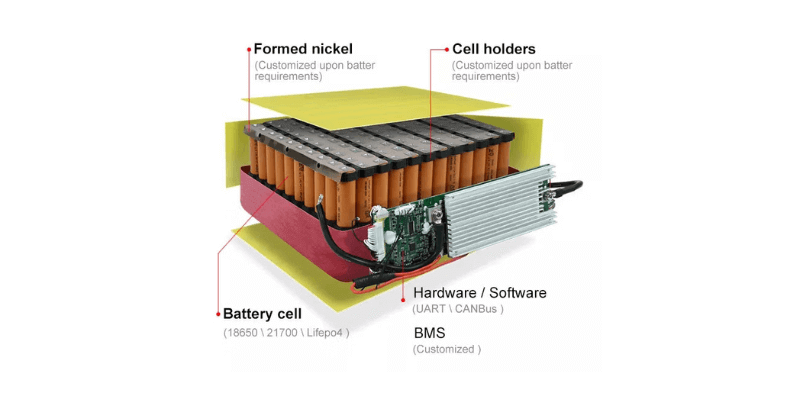

- 最適なセル配置:セルを組み合わせる 直列または並列 電圧や容量を増やすため。スタッキング 角柱状セル 高出力を確保しながら垂直方向にスペースを節約します。

- エネルギー管理: IoT デバイスのスリープ モードなどの低電力電子機器とソフトウェアを統合して、エネルギー使用を最適化します。

安全性の向上

- スマートバッテリー管理システム (BMS): 使用する BMS セルの電圧、温度、充電状態を監視します。校正された BMS は過充電を防止し、セルのバランスをとり、障害時にシャットダウンを開始します。

- 熱管理: 熱放散には相変化ポリマーまたはグラフェン層を使用します。重要な用途では、セラミックセパレーターにより燃焼のリスクを最小限に抑えることができます。

- コンプライアンス テスト: 安全認証により設計を検証し、衝突テストや高度暴露などのストレス シナリオをシミュレートします。

構造的完全性の提供

- 堅牢な素材: 衝撃吸収のために、航空宇宙グレードのアルミニウムまたは PEEK などの耐久性のあるポリマーを使用します。

- モジュラー設計: 湿気の侵入を防ぐために密封されたモジュールを使用する医療用インプラントと同様に、パックを小さなモジュールに分割して応力を分散します。

- 高度な製造: レーザー溶接と 3D プリンティングを利用して、セルとセル間の正確かつ強力な接続を実現します。 コンポーネント、障害点を最小限に抑えます。

結論

コンパクトなカスタム バッテリー パックの設計には、パフォーマンス、安全性、耐久性のバランスをとることが含まれます。シリコンアノードセルやソリッドステートセル、スマート BMS、堅牢な材料などの高度な化学は、エンジニアが小型化の課題に取り組むのに役立ちます。

業界がより小型のデバイスを求めるにつれ、バッテリー技術の革新と厳格なテストがポータブル電子機器にとって不可欠になります。材料科学、エレクトロニクス、機械工学の連携により、この分野の進歩が促進されるでしょう。