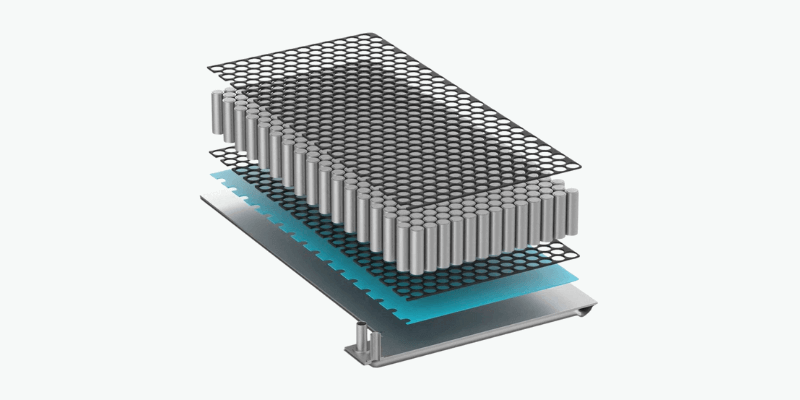

Özel Pil Paketleri Doğal olarak biraz ısı üreten şarj ve deşarj için kendi hızlarına sahip olun. Biraz sıcaklık iyidir, ancak çok fazla sorun olabilir. Çevresel sıcaklıklar da rol oynar – Sıcak koşullar zararlı olabilirken, soğuk olanlar verimliliği azaltır.

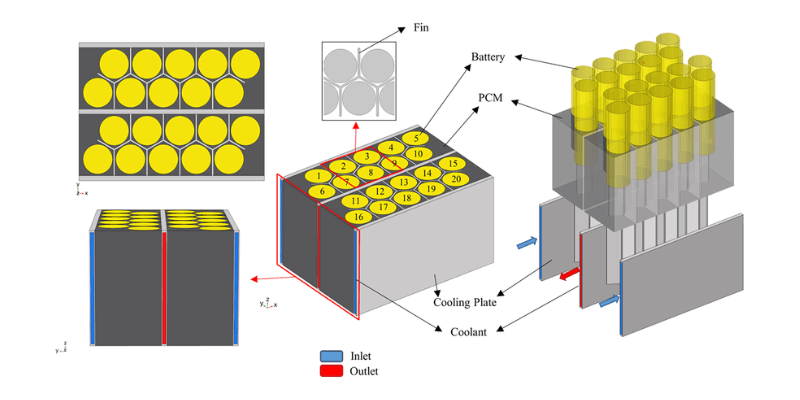

Bu nedenle bu pil paketlerinin tasarlanmasında termal yönetim önemlidir; Doğru sıcaklığı koruyarak ve kullanım ve şarj sırasında aşırı ısınmayı veya aşırı soğumayı önleyerek sorunsuz çalışmayı sağlar.

Termal yönetimi nedir?

Termal yönetim, bir sistemi çalışma sıcaklığı aralığında tutan işlemdir.

Elektronik cihazlarda, aşırı ısınmayı önlemek için fazla ısıyı dağıtmaya yardımcı olur. Çoğu sistem ısı ürettiğinden, ısı çok fazla birikirse hassas bileşenlere zarar verme riski vardır. Ayrıca, aşırı dış ısı elektroniklere de müdahale edebilir.

Mühendisler, havacılık, otomotiv, piller ve veri merkezleri gibi çeşitli endüstrilerde termal yönetim çözümleri kullanırlar. Optimal sıcaklıkların korunması tasarımda çok önemlidir, çünkü performansı ve dayanıklılığı arttırır.

Isıyı yönetmek için, genellikle ısı lavaboları ve fanlar gibi aletlere, soğutma için veya hızlı soğutma için kriyojenik sıvılarla sıvı soğutmalı sistemlere güvenirler. Ek olarak, termal mühendisler hassas alanlara ısı transferini azaltmak için yalıtım malzemeleri kullanabilirler.

Aktif ve pasif termal yönetim arasındaki fark nedir?

Mühendisler hem aktif hem de pasif teknolojiler kullanarak termal yönetim sistemleri geliştirirler.

Fan ve pompalar gibi aktif bileşenler harici bir güç kaynağı gerektirirken, ısı lavaboları ve borular gibi pasif elemanlar yapmaz.

Pasif teknoloji, sistem içindeki iletim, konveksiyon veya radyasyon gibi doğal süreçleri geliştirir.

Her iki tür de ısı dağılmasını iyileştirmeyi ve çalışma sıcaklıklarını korumayı amaçlamaktadır. Pasif araçların ekstra enerjiye ihtiyacı olmadığından, genellikle aktif termal yönetim seçeneklerinden daha bütçe dostudur.

Aktif soğutma yöntemlerine örnekler

Zorunlu Konveksiyon

Birçok aktif soğutma cihazı, sıcak parçaların etrafında hava akışını artırmak için fanlar veya üfleyiciler kullanır, bu da işleri soğumaya yardımcı olur. Sıcak havayı daha hızlı iterek, bu yöntem gerçekten konveksiyonu hızlandırır ve ısı dağılmasını daha etkili hale getirir.

Termoelektrik soğutucular

Termoelektrik soğutucular veya katı hal ısı pompaları, yarı iletkenlerle çalışırken oldukça yaygındır. İnce ve kompakttırlar, genellikle bir ısı lavabosu ve bir ısı kaynağı arasında sıkışırlar.

Onlara voltaj uyguladığınızda, iki taraf arasında bir sıcaklık farkı yaratırlar. Bu daha büyük sıcaklık boşluğu, iletim oranını artırmaya yardımcı olur.

Pasif soğutma yöntemlerine örnekler

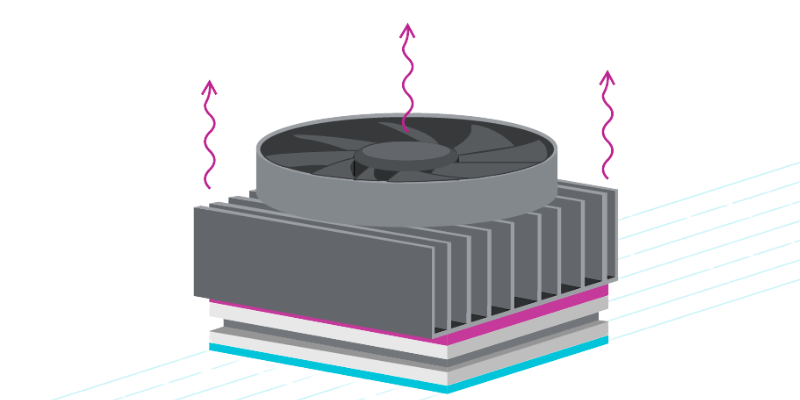

Isı Lavaboları

Isı lavaboları pasif soğutma dişlilerinde yaygındır.

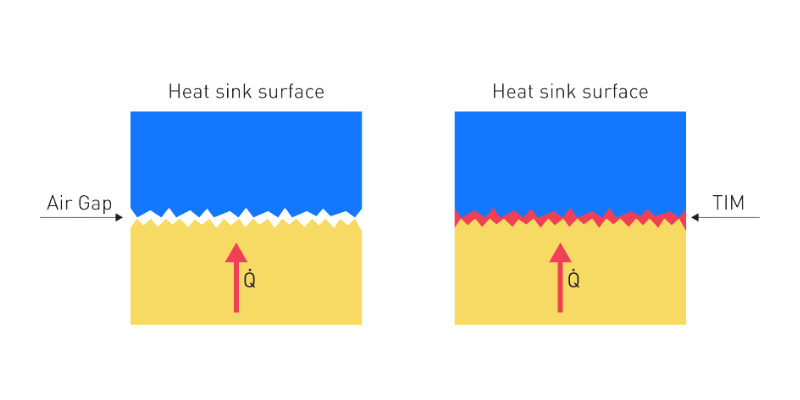

Esasen, ısıyı iyi ileten bakır veya alüminyum gibi bir metalden yapılmış bir ısı lavabosu ısı kaynağına bağlanır. Termal enerji, sıcak kısımdan iletim yoluyla metalden hareket eder ve ısı batması yüzeyinden doğal konveksiyon yoluyla çevredeki havaya salınır.

Isı yayma makineleri

Isı yayıcıları, konsantre ısıyı daha geniş bir alana dağıtmak için termal olarak iletken folyolar veya metal plakalar kullanan popüler pasif soğutma cihazlarıdır. Tipik olarak ısı kaynağı ve ikincil ısı eşanjörleri arasında bir ara malzeme görevi görürler.

Farklı pil kimyası için termal yönetim

Farklı pil türleri en iyi belirli sıcaklık aralıklarında çalışır. İşte ideal yükleri ve deşarj sıcaklıkları hakkında hızlı bir özet:

- Lityum iyon: 0 ° C ile 45 ° C arasında yük; -20 ° C'den 60 ° C'ye deşarj

- NIMH/NICAD: 0 ° C ile 45 ° C arasında yük; -20 ° C'den 65 ° C'ye deşarj

- Kurşun Asit: Hem şarj hem de deşarj -20 ° C'den 50 ° C'ye kadar iyidir

Üreticiler, pillerin sıcaklık değişiklikleri de dahil olmak üzere çeşitli durumlarda nasıl performans gösterdiğini simüle etmek için müşteri için tasarlanmış teknik verilere ve bilgisayar modellerine güvenir. Bu modeller, tasarımcıların termal sınırları anlamalarına yardımcı olur, böylece etkili termal yönetim sistemleri oluşturabilirler, böylece pil paketlerinin her türlü koşulda iyi çalışmasını sağlar.

Piller termal yönetimden yoksunsa ne olur

Elektrik akımındaki direnç nedeniyle piller ısınır. Akım bağlantılar ve elektrolitler gibi parçalardan akarken ısı üretir. Daha fazla direnç, daha fazla ısı ile sonuçlanır, bu da malzemeleri aşabilir ve pil kapasitesini azaltabilir, hatta bazen neden olur termal kaçak.

Tersine, soğuk sıcaklıklar iletkenliği azaltarak elektronların hareket etmesini ve direnci arttırmasını zorlaştırır. Bu, bazı pil türleriyle düşük performans ve şarj sorunlarına yol açabilir.

Çözüm

Termal kaçak ve azaltılmış üretkenlik, piller için temel termal yönetim sorunlarıdır. Birçok şirket, sertifika için termal testleri geçmek için pil paketlerine ihtiyaç duyar. Özel uygulamanızı ve endüstrinizi anlamak, güvenli çalışmayı gösteren uyumlu bir pil paketinin tasarlanmasına yardımcı olur.