Tại Holo Battery, chúng tôi đã chế tạo gói pin tùy chỉnh trong hơn 18 năm. Chúng tôi hiểu rằng việc phát triển một giải pháp năng lượng mới sẽ đặt ra những câu hỏi quan trọng về hiệu suất và độ an toàn. Đó là lý do tại sao chúng tôi tạo Câu hỏi thường gặp này để giải quyết các thắc mắc phổ biến từ các kỹ sư và người quản lý dự án, hỗ trợ bạn trong hành trình sử dụng bộ pin tùy chỉnh của mình.

Thiết kế cốt lõi và lựa chọn thành phần

Câu hỏi: Làm thế nào để bạn biết nên chọn loại ô nào cho dự án của mình?

Lựa chọn cell là nền tảng cho hiệu suất của bộ pin của bạn. Sự lựa chọn phụ thuộc vào sự cân bằng cẩn thận giữa các yêu cầu chính của ứng dụng của bạn:

- Mật độ năng lượng (Wh/kg) so với Mật độ năng lượng (W/kg): Thiết bị của bạn có cần thời gian chạy dài (ví dụ: UAV, thiết bị y tế) hoặc nguồn điện bùng nổ cao (ví dụ: dụng cụ điện, robot) không? Pin Lithium Niken Mangan Cobalt (NMC) cung cấp hiệu suất cao hơn mật độ năng lượng, trong khi Liti Sắt Phosphate (LiFePO4) vượt trội trong vòng đời.

- Tuổi thọ chu kỳ: Cần bao nhiêu chu kỳ sạc/xả? LiFePO4 mang lại vòng đời dài nhất, lý tưởng cho việc lưu trữ năng lượng mặt trời và sử dụng trong công nghiệp.

- Môi trường hoạt động: Pin có gặp phải nhiệt độ khắc nghiệt không? Một số chất hóa học như pin natri-ion, tốt hơn cho điều kiện lạnh.

- Hồ sơ An toàn: Xem xét các rủi ro về an toàn; LiFePO4 được biết đến với tính ổn định nhiệt.

Xác định công suất và điện áp mà thiết bị của bạn cần, bao gồm cả dòng điện. Các pin khác nhau có công suất và tốc độ xả khác nhau, vì vậy hãy xem xét các yếu tố hình dạng pin để đáp ứng các ràng buộc về kích thước. Các kỹ sư của Holo Battery phân tích các yếu tố này để đề xuất pin Hạng A từ các nhà cung cấp có uy tín phù hợp với mục tiêu hiệu suất và chi phí cho dự án của bạn.

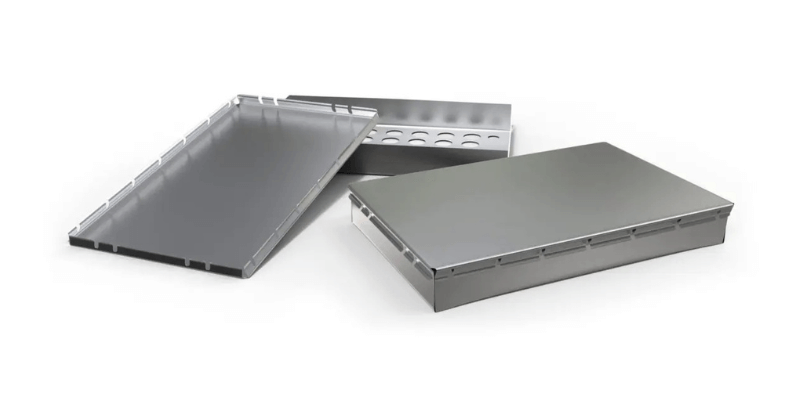

Câu hỏi: Làm thế nào để bạn xác định loại vật liệu nào sẽ được yêu cầu cho vỏ bọc?

Khi lựa chọn vật liệu vỏ bọc phù hợp, chúng tôi xem xét các yếu tố như yêu cầu xếp hạng IP, trọng lượng, quản lý nhiệt và tuân thủ các quy định (chẳng hạn như tính dễ cháy UL94).

Nếu bạn cần một lựa chọn nhẹ, giá cả phải chăng với khả năng chống va đập tốt và hình dạng tùy chỉnh, các loại nhựa như ABS và PC là những lựa chọn tuyệt vời.

Tuy nhiên, để có độ bền cao, che chắn EMI hiệu quả và quản lý nhiệt trong các môi trường đòi hỏi khắt khe như môi trường công nghiệp hoặc quân sự, các kim loại như nhôm và thép là lý tưởng.

Chúng tôi sẵn sàng giúp bạn chọn vật liệu tốt nhất để đảm bảo tế bào của bạn được an toàn, quản lý nhiệt hiệu quả và tích hợp hoàn hảo với thiết kế sản phẩm của bạn.

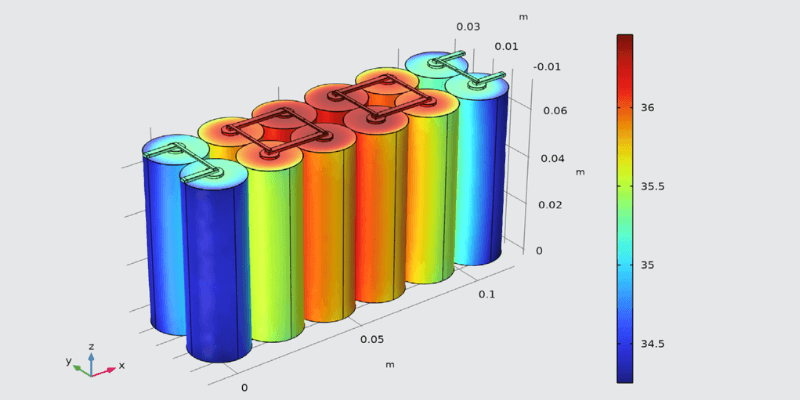

Câu hỏi: Bạn dự định kiểm soát nhiệt độ trong vỏ pin như thế nào?

Hiệu quả Quản lý nhiệt không thể thương lượng vì sự an toàn và lâu dài. Quản lý nhiệt kém dẫn đến hiệu suất kém hơn, hao mòn nhanh hơn và tiềm ẩn các vấn đề an toàn. Đây là cách chúng tôi giải quyết nó:

- Làm mát thụ động: Chúng tôi sử dụng các vật liệu dẫn nhiệt như vỏ nhôm và miếng đệm giao diện nhiệt giúp tản nhiệt một cách tự nhiên, lý tưởng cho nhu cầu điện năng vừa phải.

- Làm mát chủ động: Đối với các tình huống sử dụng công suất cao, chẳng hạn như hệ truyền động xe điện hoặc bộ lưu trữ năng lượng tiên tiến, chúng tôi sử dụng quạt hoặc làm mát bằng chất lỏng để quản lý lượng nhiệt dư thừa.

- Tích hợp BMS: Tùy chỉnh của chúng tôi Hệ thống quản lý pin theo dõi nhiệt độ tế bào trong thời gian thực. Nếu quá nhiệt xảy ra, họ có thể giảm tốc độ sạc/xả hoặc tắt hệ thống để đảm bảo an toàn.

Vai trò của Hệ thống quản lý pin (BMS)

Câu hỏi: Có phải tất cả các bộ pin đều cần BMS để kiểm soát việc sạc và xả không?

Không phải tất cả các bộ pin đều cần BMS, nhưng các bộ pin lithium-ion thì có. BMS rất cần thiết cho:

- An toàn: Nó bảo vệ chống quá tải, xả quá mức, quá dòng và ngắn mạch.

- Hiệu suất & Tuổi thọ: Nó cân bằng các tế bào để đảm bảo độ mòn đồng đều và tối đa hóa tuổi thọ của chu kỳ.

- Giám sát: Nó cung cấp dữ liệu về Trạng thái sạc (SoC), Trạng thái sức khỏe (SoH) và các thông số khác thông qua các giao thức như CANBus hoặc Bluetooth.

Câu hỏi: Làm thế nào để bạn xác định thời điểm nên sạc pin nếu pin không được sử dụng hoặc đã được bảo quản lâu dài?

Pin lithium-ion có tốc độ tự xả thấp nhưng cần có quy trình cụ thể để lưu trữ lâu dài.

Chúng tôi khuyên bạn nên bảo quản pin ở mức 30-50% SoC ở nơi khô ráo, thoáng mát. Để kiểm kê hoặc sử dụng theo mùa, BMS thông minh sẽ sử dụng năng lượng thấp “ngủ” chế độ nhưng định kỳ kiểm tra điện áp. Nếu điện áp giảm xuống dưới ngưỡng an toàn, nó sẽ cảnh báo người dùng về việc sạc bảo trì.

Câu hỏi: Cầu chì đặt lại được có thể sử dụng theo gói được không?

Cầu chì có thể đặt lại hoặc PPTC không tốt cho việc bảo vệ chính trong bộ pin hiệu suất cao. Chúng có điện trở cao hơn và có thể bị ngắt do thay đổi nhiệt độ chứ không chỉ do quá dòng.

Do đó, chúng tôi ưu tiên sử dụng các bộ chuyển mạch trạng thái rắn chuyên dụng trong BMS, cùng với các cầu chì thông thường cho những sự cố lớn hiếm gặp đó. Cách tiếp cận này cho phép chúng tôi xây dựng một thiết lập an toàn vững chắc, nhiều lớp.

Chứng nhận, che chắn và chi phí

Câu hỏi: Tấm chắn EMI/RFI có cần thiết cho bộ pin không?

Đối với các gói cơ bản chỉ có các ô và bảo vệ cơ bản, bạn thường không cần phải lo lắng về việc che chắn EMI/RFI.

Tuy nhiên, đối với các gói thông minh có các tính năng như BMS, hệ thống liên lạc, bộ chuyển đổi DC-DC hoặc dòng điện chuyển mạch cao, việc che chắn có thể cần thiết.

Nó thực sự phụ thuộc vào các quy định và độ nhạy của thiết bị bạn đang làm việc.

Câu hỏi: Holo Battery có thể hỗ trợ chứng nhận bộ pin cho khách hàng được không?

Hoàn toàn có thể. Là nhà sản xuất được chứng nhận ISO, chúng tôi có nhiều kinh nghiệm giúp khách hàng thực hiện quy trình chứng nhận. Chúng tôi có thể quản lý và bảo đảm tất cả các chứng nhận quốc tế chính cho bộ pin của bạn, bao gồm nhưng không giới hạn ở:

- UL 2054 / UL 2580 (Bắc Mỹ)

- IEC 62133 (Quốc tế)

- EC (Châu Âu)

- UN38.3(Giao thông vận tải)

Bằng cách sử dụng các tế bào được chứng nhận trước và các thành phần, chúng tôi đảm bảo sản phẩm của bạn tiếp cận thị trường một cách nhanh chóng và tuân thủ!

Câu hỏi: Chi phí phát triển, bao gồm cả chứng nhận cho pin là bao nhiêu?

Chi phí có thể thay đổi đáng kể dựa trên mức độ phức tạp của dự án, số lượng công việc cần thiết và các chứng chỉ cần thiết. Các yếu tố chính ảnh hưởng đến chi phí bao gồm:

- Kỹ thuật tùy chỉnh: Sự phức tạp của BMS, thiết kế cơ khí và quản lý nhiệt.

- Nguyên mẫu: Số lượng đơn vị nguyên mẫu cần thiết để thử nghiệm.

- Chứng nhận: Các tiêu chuẩn và khu vực cụ thể mà bạn đang nhắm mục tiêu.

- Dụng cụ: Chi phí cho các khuôn hoặc đồ đạc tùy chỉnh để sản xuất quy mô lớn.

Tại Holo Battery, chúng tôi tin vào sự minh bạch. Lời hứa báo giá nhanh của chúng tôi cung cấp ước tính ban đầu đơn giản. Chúng tôi hợp tác với bạn để thiết kế tiết kiệm chi phí nhất có thể mà không ảnh hưởng đến sự an toàn hoặc hiệu suất, đảm bảo bạn nhận được giá trị tốt nhất.

Có thêm câu hỏi? Đừng lo lắng! Nhóm tại Holo Battery sẵn sàng trợ giúp. Liên hệ với chúng tôi hôm nay và hãy trò chuyện về nhu cầu về bộ pin tùy chỉnh của bạn.