Key Takeaway:

- Lithium-ion battery packs are complex assemblies that include cells, a battery management system (BMS), passive components, an enclosure, and a thermal management system. They power a vast array of applications, from consumer electronics to electric vehicles, and require careful engineering to ensure safety, efficiency, and reliability.

A lithium-ion battery pack is an assembly of lithium-ion cells, a battery management system, and various supporting components all contained within an enclosure. It provides rechargeable energy storage and power for countless consumer electronics, electric vehicles, grid storage systems, and other industrial applications.

While lithium-ion cells provide the basic electrical capacity, the other integrated components are equally critical in enabling safe, efficient, and reliable functionality. In this guide, we’ll take a closer look at the technical aspects of each core lithium-ion battery pack component.

Key Components Overview

Lithium-ion battery packs include the following main components:

- Lithium-ion cells – The basic electrochemical unit providing electrical storage capacity. Multiple cells are combined to achieve the desired voltage and capacity.

- Battery Management System (BMS) – The “brain” monitoring cell conditions and controlling safety and performance.

- Passive components – Provide structure, interconnection, insulation, and cooling.

- Enclosure – Houses and protects all internal components.

- Thermal management system – Maintains optimal cell temperatures for operation.

- Additional electronics – Added features enhancing functionality and integration.

Next, we’ll explore each of these components in greater technical detail.

Lithium-Ion Cells: The Electrochemical Power Source

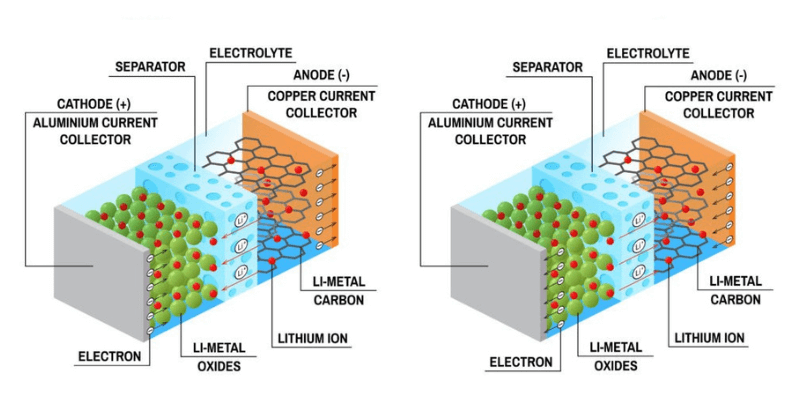

Lithium-ion cells utilize lithium ion intercalation chemistry to reversibly store electrical energy electrochemically. Within the cell, positively charged lithium ions shuttle between a graphite anode and lithiated metal oxide cathode as the cell charges and discharges. An organic electrolyte allows ion transport while a porous separator prevents electrical contact between electrodes.

Cells come in various standard sizes and form factors:

- Cylindrical (e.g. 18650, 21700, 4680): spirally wound electrode/separator layers in a cylindrical metal can. Higher power density but lower energy density compared to pouch cells. Common formats:

- 18650 – 18mm diameter, 65mm height, typical capacity of 1.5–3Ah

- 21700 – 21mm diameter, 70mm height, up to 5Ah capacity

- 4680 – 46mm diameter, 80mm height, 10-50Ah capacity

- Prismatic – alternating cathode, anode and separator layers stacked and folded into a prismatic aluminum housing. Maximizes volumetric energy density but lower power density. Common formats:

- 10Ah and 30Ah capacities at low C-rates

- Dimensions around 100 x 200 x 10mm

- Pouch – electrodes and separator sealed in a metallized plastic laminate pouch. Also known as polymer cells. Flexible and lightweight. Cost effective but less durable casing. Typical capacity ratings from 1Ah to over 300Ah.

Lithium-ion cells also utilize different cathode chemistries, impacting voltage, capacity, and safety:

- Lithium cobalt oxide (LCO) – 3.6V nominal voltage, high energy density but safety concerns at elevated temperatures

- Lithium manganese oxide (LMO) – 3.7V, safer and longer cycle life but lower capacity

- Lithium iron phosphate (LFP) – 3.2V, very safe and durable but lower energy density

- Lithium nickel manganese cobalt oxide (NMC) – 3.6/3.7V, high capacity and energy density but more complex manufacturing

- Lithium nickel cobalt aluminum (NCA) – 3.6V, high capacity and power density but shorter battery life

When selecting cells, engineers evaluate parameters like nominal voltage, capacity, C-rate, cycle life, form factor, safety, cost, and availability to meet application requirements. High capacity NMC and NCA chemistries have become common for high performance applications.

Battery Management System (BMS)

The battery management system serves as the “brain” controlling overall operation of the battery pack. The BMS monitors cell conditions, controls safety mechanisms, balances cells, and provides communication interfaces. The complexity of the BMS depends on pack size and functionality. Small consumer BMS may just include:

- Monitoring cell voltages and temperatures

- Preventing overcharge and over-discharge

- Balancing cell voltages

While large EV traction pack BMS provides extensive functionality:

- High accuracy monitoring of voltage (±15mV), current (±1-2%), and temperature (±1°C) for each cell

- Active cell balancing via shunting or multi-winding transformers

- Controlling contactors and fuses for electrical isolation

- Complex state of charge and health estimation algorithms

- Thermal management via cooling system control

- High speed critical fault detection – open/short circuit, overtemperature

- Hundreds of sensor inputs and control outputs

- Vehicle communication interfaces – CAN, LIN, FlexRay, Automotive Ethernet

- Secure authentication, tamper protection, firmware updates over the air

- Detailed data logging for diagnostics and cycle counting

source: ResearchGate

The BMS hardware typically consists of sensor interface ICs, ADCs, microcontrollers, and power management circuits mounted on a printed circuit board. High voltage insulation and robust connections are critical for safety and reliability.

Passive Components

In addition to cells and the BMS, lithium-ion battery packs include various passive components:

- Bus bars – Provide low resistance connections between cells and terminals. High current capacity required – up to 1000A in EV packs. Copper or aluminum bus bars may be bare, plated, or coated. Bus bar design minimizes inductance while maintaining isolation.

- Thermal interface material – Used between cells and enclosure walls or cooling channels. Silicone elastomers, thermally conductive tapes, and gap filling pads maximize heat transfer. Phase change materials offer high thermal capacitance.

- Adhesives and tapes – Provide electrical insulation and vibration resistance. Materials include polyurethane, acrylic adhesives and silicone. Double sided thermally conductive tapes are common. Strict UL94 V-0 flammability rating.

- Fuses and contactors – Protect against overcurrent faults. Also allow safe electrical isolation. High voltage and current ratings required. Fuses may be integrated into BMS. Pre-charge circuits limit inrush current.

- Cell interconnects – Join cell terminals in series. Must handle high current density. Ultrasonic, laser, and resistance welding used.

Careful selection of these passive components ensures electrical, thermal, and mechanical integrity of the battery pack under demanding conditions.

Battery Pack Enclosure

The battery pack enclosure or housing provides:

- Protection – Shields cells from mechanical abuse, impact, dust, fluids. Allows only proper electrical connections. Provides IP rating based on application.

- Structural support – Provides required rigidity for cell stacking and mounting. Interfaces with application frame and brackets.

- Cooling channels – Allows airflow or liquid coolant circulation across cells and BMS. May include integrated cooling fins.

- Insulation – Electrically isolates high voltage components like bus bars and terminals.

- Environmental sealing – Prevents moisture ingression. Necessary for lithium-ion chemistries.

Common enclosure materials include metals like aluminum for excellent thermal properties, and engineered plastic blends for lighter weight and corrosion resistance. Metallized and carbon fiber reinforced plastics provide structural rigidity and shielding.

Enclosures often feature removable access panels for servicing and modular pack designs for installation flexibility. Structural adhesives, gaskets, and insulating membranes keep components securely mounted and isolated.

Thermal Management System

Maintaining proper cell temperatures is crucial for safe and optimal performance of lithium-ion battery packs. Although lithium-ion cells perform well around 15-35°C, operation outside this range degrades performance and lifetime:

- Discharge capacity decreases below freezing. Internal resistance increases.

- Above ~50°C rapid capacity fade and ageing occur.

- Above ~60°C risk of thermal runaway escalates.

Thus the thermal management system must cool cells during operation and heat them when static in cold ambient conditions. Typical cooling methods include:

- Passive air – Cooling via fins and channels. Used in smaller packs with lower heat output.

- Forced air – Axial or centrifugal fans improve airflow rate and heat transfer. Ducts optimize flow distribution.

- Liquid cooling – Jackets, plates or microchannels circulation a water/glycol mix or dielectric fluid. Very effective for high power packs >5kW.

- Phase change materials – Wax-like materials absorbing heat as they melt. Used in enclosures or as thermal pads.

- Thermoelectric – Peltier devices generate a temperature differential when powered. Compact solid-state cooling.

Heating is also critical for cold climate operation. Heating methods include:

- Electric heaters – Resistive heaters attached to pack enclosure.

- Heat pumps – Reverse thermoelectric devices or compact refrigerant loops.

- Waste heat – Capturing resistive losses from charging and discharging.

The BMS monitors cell temperatures and controls cooling or heating accordingly based on proprietary control algorithms. Large battery packs may divide into thermal zones with independent temperature regulation.

Additional Components

Depending on cost, form factor, and application requirements, lithium-ion battery packs may include additional components:

- Wake-up circuit – Wakes sleeping BMS when charge/discharge begins. Improves standby current.

- Cell balancing circuits – Active balancing provides more precision than passive balancing alone. Requires added complexity.

- Precharge circuit – Limits inrush current when connecting pack. Uses resistors or active switching. Protects BMS and contactors.

- Charger – On-board charging control electronics for DC fast charging. Removes the need for an external charger.

- Communications – Beyond a basic BMS interface, packs may include wireless modules or Power Line Communication (PLC) for remote control and diagnostics.

- Heaters – Provide controlled heating for cold weather operation. Help achieve optimal cell temperatures.

- Cell switching – Switches groups of cells on/off for thermal management and balancing. Requires many added switches and complex control logic.

- Status LEDs – Visually indicate basic pack status to the user – charging, fault, standby etc.

Lithium-ion Battery Pack Applications

Now that we’ve explored the internal components, let’s examine how lithium-ion battery packs are applied in major industries and applications:

- Electric Vehicles – Provide propulsion power to fully electric and hybrid vehicles. Require very high capacity (50-100kWh), power density, safety and cycle life. Complex liquid cooled designs.

- Consumer Electronics – Mobile phones, laptops, power tools and other portable devices. Focus on cost, compact size and lightweight. Air cooled pouch or prismatic cells in plastic enclosures. 1-100Wh capacity range.

- Aerospace – Used in aircraft for emergency power and to start engines. Durable designs withstand vibration. Safety and reliability are critical.

- Stationary Storage – Grid energy storage, backup power, off-grid solar/wind systems. Focus on low cost, long cycle life. Air/liquid cooled in racks or containers.

- Medical Devices – Implantable and wearable medical devices. Very compact, safe and durable batteries are required. Ultrathin flexible cells down to 100 microns thick.

This overview illustrates the wide range of lithium-ion battery pack designs tailored to meet vastly different application requirements across industries.

Lithium-Ion Battery Safety

Working with lithium-ion battery packs demands proper safety precautions. While generally safe if designed and handled correctly, defective or damaged cells can rapidly overheat and ignite. Key risks include:

- External short circuit – quickly leads to high current and heating.

- Internal short circuit – caused by cell damage. Most dangerous failure mode.

- Thermal runaway – self heating until cell vents or burns. Can propagate between cells.

- Overcharge – cell voltage over limits causes electrolyte breakdown.

- Crush/impact – crushes separator allowing internal short circuit.

- Incorrect assembly – loose components and high resistance points generate localized heat.

The BMS and other protection circuits are designed to minimize these risks during normal operation and faults. However, workers should take precautions when transporting, installing, servicing or disposing of lithium-ion battery packs:

- Wear appropriate PPE – eye protection, gloves, flame resistant clothing. Avoid metallic jewelry.

- Use insulated tools marked for use on live battery packs.

- Avoid short circuiting terminals or bus bars.

- Strictly adhere to shipping and handling regulations for lithium batteries.

- Discharge spent batteries to save voltage before disposal.

- Store and charge on nonflammable surfaces away from combustibles.

- Have an extinguisher on hand in case of a fire emergency.

Following best practice guidelines for safe handling is essential when working with lithium-ion battery packs.

Conclusion

Lithium-ion battery packs have many components, including cells, BMS electronics, thermal management, and enclosure design. Engineers must balance cost, performance, safety, and manufacturability when designing battery packs.

Continued technology improvements will enable safer, cheaper, smaller, and more powerful lithium-ion packs. Companies must stay up-to-date on the latest advancements to remain competitive.

Related Articles: