Bài học chính

- The Compliance Gap: Cell certificates (EN 62133) don’t cover battery packs. A pack with a BMS is legally an “apparatus” requiring its own EMC compliance.

- The #1 Failure Cause: 90% of EMC failures come from BMS common-mode noise failing radiated emissions tests (EN 61000-6-3), not cell safety issues.

- The Real Cost: Failed EMC tests cost $2,500+ in lab fees and 6-8 weeks in delays. Pre-compliance scanning prevents this.

- 2026 EU Reality: The Battery Regulation (EU 2023/1542) is now enforced. Market surveillance requires complete technical files, not just transport certificates.

- The Solution: Design for EMC from day one – use pre-compliance scanning, common-mode filtering, and proper cable management.

If you ship gói pin tùy chỉnh to Europe, you have likely noticed stricter customs inspections and more technical questions from customers.

This is not temporary.

The EU Battery Regulation (2023/1542) is in full enforcement. Market Surveillance Authorities are actively requesting technical files for battery packs.

Yet we still see a critical mistake: relying on cell certificates to justify selling a complete battery pack.

The issue is not the chemistry. It is the electronics.

A battery pack with an active BMS is legally an “apparatus” under the EMC Directive. If your supplier cannot explain “common-mode noise” or provide pack-level test reports, your product faces immediate market withdrawal risk.

This guide explains why and what to do about it.

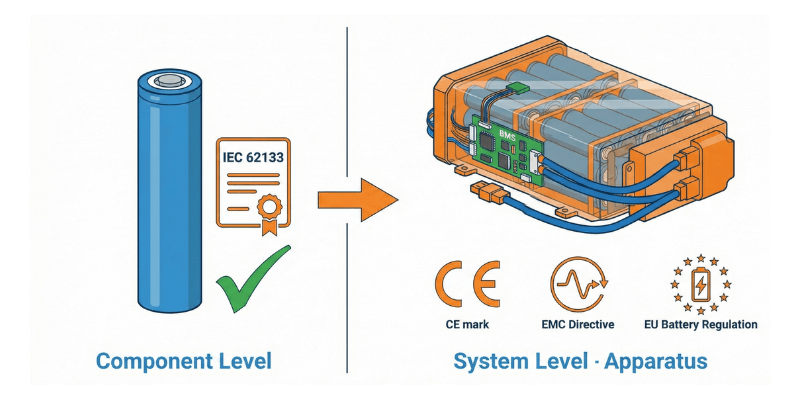

Why “Cell Certification” ≠ “Pack Certification”

Many teams assume: “Our cells have IEC 62133 reports, so we are compliant.”

This is incorrect.

A cell certificate covers the component. A battery pack is a system.

The Legal Distinction

| Item | Cell | Gói pin |

| Sự định nghĩa | Bare electrochemical unit (e.g., 18650, 21700) | Assembly with BMS, wiring, enclosure, connectors |

| Primary Standard | EN 62133-2 (Chemical Safety) | EN 61000-6-3 (EMC Emissions) + EN 61000-6-1 (Immunity) |

| What It Tests | Fire, explosion, thermal runaway | Electronic noise, electromagnetic interference, system safety |

| Legal Status | Component | End product (requires CE marking) |

| Market Risk if Missing | Low (internal use) | Critical (seizure, fines, recall) |

Selling a battery pack in the EU with only a cell certificate is technically documentation fraud.

What Changes When You Add a BMS

A custom pack adds components the cell report never tested:

- BMS with switching MOSFETs

- Long DC power cables (act as antennas)

- Metal enclosure or mounting frame

- Connectors and charging interfaces

- Communication protocols (CAN, UART, Bluetooth)

Each of these creates electromagnetic compatibility requirements.

Official Source: 📄 EMC Directive 2014/30/EU (EUR-Lex)

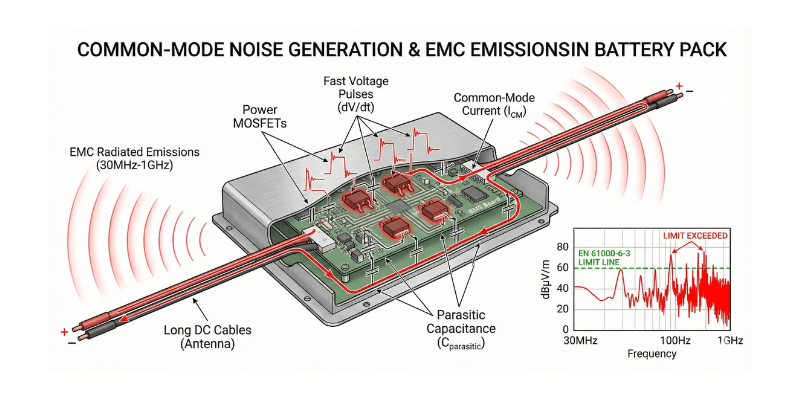

Why Battery Packs Fail EMC

Based on industry data from 6000+ custom battery projects:

- 90% of EMC failures are emissions-related (not safety)

- Primary cause: BMS common-mode noise

- Typical failure point: Radiated emissions at 30 MHz – 1 GHz

What Is Common-Mode Noise

Your BMS uses MOSFETs to switch power on and off, thousands of times per second.

Here is the chain reaction:

- The Source: Fast voltage switching creates high-frequency noise

- The Coupling: Parasitic capacitance between components and metal parts

- The Path: Noise flows through battery cables as common-mode current

- The Antenna: Long DC cables radiate this noise into the environment

- The Failure: Lab measures emissions above EN 61000-6-3 limits

Typical Failure Modes

| Problem | Frequency Range | Root Cause | Engineering Fix |

| Radiated Emissions | 30 MHz – 1 GHz | Common-mode noise on cables | Common-mode chokes, cable length limits, shielding |

| Conducted Emissions | 150 kHz – 30 MHz | Differential-mode noise from DC/DC | X/Y capacitors, input filtering, PCB layout optimization |

| ESD Immunity | Transient events | Poor grounding/discharge path | TVS diodes, bonding strategy, conductive gaskets |

Two packs with identical cells can behave completely differently in EMC testing. The difference is the electronics and wiring design.

Pre-Compliance Testing

A pre-compliance scan is an early EMC measurement using a spectrum analyzer and antennas.

It is NOT:

- A legal substitute for official testing

- A certification

It IS:

- A diagnostic tool to find noise sources early

- A cost-effective way to avoid expensive lab failures

- Critical evidence for your technical file

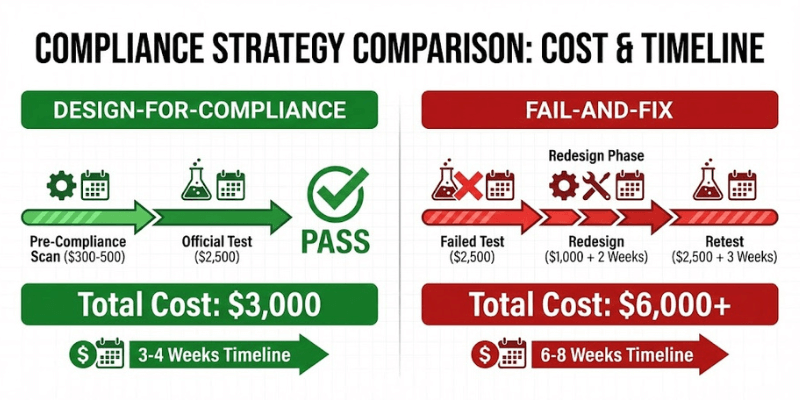

The Cost Reality

Scenario 1: Design-for-Compliance (First-Pass Success)

- Pre-compliance scan: $300-$500

- Official lab test: $2,000-$3,500

- Timeline: 3-4 weeks

- Total: $3,000, one cycle

Scenario 2: Fail-and-Fix (Typical Reality)

- Initial failed test: $2,500

- PCB/BMS redesign + new samples: $1,000 + 2 weeks

- Lab re-test: $2,500 + 3 weeks (full price)

- Total: $6,000 + 6-8 weeks delay

The $2,500 test that kills your $200,000 launch.

Pre-Compliance Checklist

STEP 1: DEFINE THE PRODUCT

- Exact BMS model and firmware version

- Cable lengths and routing (as installed)

- Enclosure material and grounding strategy

- Connectors and external interfaces

- Operating modes (charge, discharge, standby, comms)

STEP 2: IDENTIFY APPLICABLE STANDARDS

- Intended environment (residential vs industrial)

- EMC standard: EN 61000-6-3 (residential) or EN 61000-6-4 (industrial)

- Safety standard: EN 62133-2 (system level)

- EU Battery Regulation requirements (see Part 4)

STEP 3: ENGINEERING DESIGN REVIEW

- BMS switching nodes identified

- Common-mode choke specified or space reserved

- Cable return paths analyzed

- Y-capacitor safety evaluation (if used)

- Enclosure bonding strategy documented

STEP 4: PRE-COMPLIANCE SCAN

- Test with real cable lengths (not lab-optimized setup)

- Document worst-case configuration

- Photograph test setup

- Record failing frequencies

- Estimate margin to limits

STEP 5: DOCUMENTATION PREPARATION

- Create technical file folder structure (see Part 4)

- Draft installation instructions

- Define cable length limits for end users

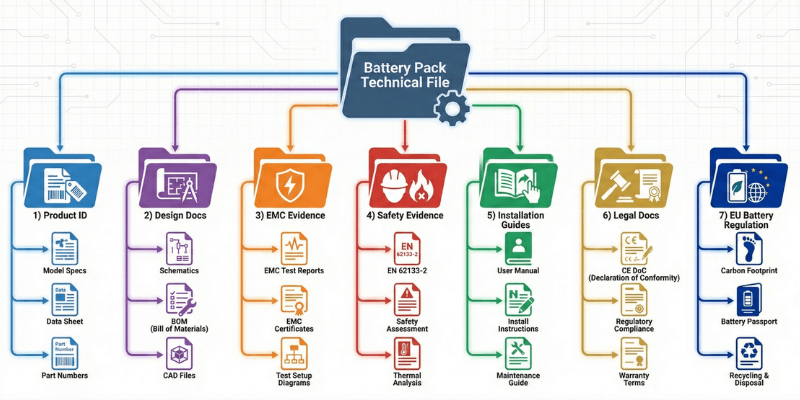

The Technical File

When market surveillance or an OEM customer asks for compliance evidence, you need a pack-level technical file.

1. Product Identification

- Model number and variant matrix

- Rated voltage, capacity, power

- Intended use and environment classification

2. Design Documentation

- Schematics (highlight EMI filtering components)

- PCB layout notes (critical traces, grounding)

- Bill of Materials (BOM) with EMC part callouts

- Enclosure drawings and bonding strategy

3. EMC Evidence

- Pre-compliance scan summary with photos

- Official EMC test reports (EN 61000-6-1 and -6-3)

- Test configuration documentation

- Margin analysis (how close to limits)

4. Safety Evidence

- System-level safety testing (EN 62133-2)

- Risk assessment (including foreseeable misuse)

- Thermal, mechanical, electrical abuse testing

5. Installation & Use

- User manual tied to tested configuration

- Cable length limits

- Grounding requirements

- Warning labels

6. Legal Documents

- EU Declaration of Conformity (DoC)

- Signed by legal manufacturer

- Lists all applied directives and standards

7. EU Battery Regulation Compliance

- RoHS/REACH substance declarations

- Carbon footprint data (for industrial/EV >2kWh)

- Supply chain due diligence records

- Battery passport preparation (2027 deadline approaching)

Official Source: 📄 EU Battery Regulation (EU) 2023/1542 (EUR-Lex)

The 2026 EU Regulatory Landscape

The EU Battery Regulation (2023/1542) is no longer “future planning.”

Key requirements now active or ramping up:

| Requirement | Applies To | Status 2026 |

| Carbon Footprint Declaration | Industrial/EV batteries >2kWh | Ramping up (check delegated acts) |

| Supply Chain Due Diligence | Lithium, cobalt, nickel sourcing | In effect |

| Labeling & QR Codes | All categories | Mandatory |

| Battery Passport (Digital) | Industrial/EV batteries | 2027 deadline |

What This Means for You

- “Legacy paperwork” is no longer accepted

- You must demonstrate EU-specific compliance

- Technical files are audited, not just filed

- Start building battery passport data architecture now

Phần kết luận

EMC compliance is not just a checkbox. It is proof that your engineering is sound.

Certification failures happen when teams treat EMC as a “lab problem” instead of a design requirement.

The reliable path:

- Define your product and environment early

- Design filtering and grounding into the BMS

- Run pre-compliance scans during prototyping

- Build a complete technical file as you go

- Book the official lab test with confidence

Don’t let a $2,500 test kill your $200,000 product launch.

Câu hỏi thường gặp

If my cells have IEC/EN 62133 reports, do I still need EMC testing for the pack?

Yes. Cell reports cover component safety (fire, explosion). They do not cover pack-level electromagnetic emissions or immunity. A pack with an active BMS is legally an “apparatus” requiring its own EMC compliance under Directive 2014/30/EU.

What is the #1 reason custom battery packs fail EMC testing?

Common-mode noise from BMS switching. Rapid voltage changes in MOSFETs create high-frequency noise that couples into DC cables, which then act as antennas. This causes radiated emissions failures in the 30 MHz – 1 GHz range, typically violating EN 61000-6-3 limits.

How much does battery pack EMC testing cost in 2026?

$2,000-$3,500 USD for a full EN 61000-6-3 emissions test at an accredited lab. If you fail and need to retest, labs typically charge the full fee again, plus you incur redesign costs (~$1,000) and 6-8 weeks of project delay.

Can pre-compliance scans replace official EMC testing?

No. Pre-compliance scans are engineering diagnostic tools, not legal compliance evidence. However, they are critical for identifying noise issues before paying for official lab tests, significantly increasing first-pass success rates.

Which EMC standard should I use? EN 61000-6-3 or EN 61000-6-4?

It depends on intended environment. EN 61000-6-3 applies to residential/commercial/light-industrial environments (most common for battery packs). EN 61000-6-4 is for heavy industrial environments only. Document your environment classification and consult your test lab to confirm.

Do shielded cables guarantee an EMC pass?

No. Shielding only works when termination, bonding, and return paths are properly engineered. Poor shield termination can sometimes worsen emissions.