La creciente demanda de dispositivos electrónicos portátiles más pequeños, livianos y potentes depende de los avances en batería de iones de litio (iones de litio) tecnología. El diseño de paquetes de baterías para dispositivos modernos requiere equilibrar la densidad de energía, la seguridad, el tamaño, el peso, el costo y el cumplimiento normativo.

Limitaciones de dimensiones y peso del paquete de baterías

Los paquetes de baterías más grandes generalmente entregan mayor corriente durante períodos más prolongados.

Sin embargo, los dispositivos portátiles enfrentan limitaciones de peso y espacio, lo que requiere que los fabricantes diseñen paquetes livianos que aún proporcionen una energía sustancial.

Las baterías de iones de litio están disponibles en varios formatos para estos dispositivos, incluidos cilíndrico, prismáticoy células de polímero de bolsa.

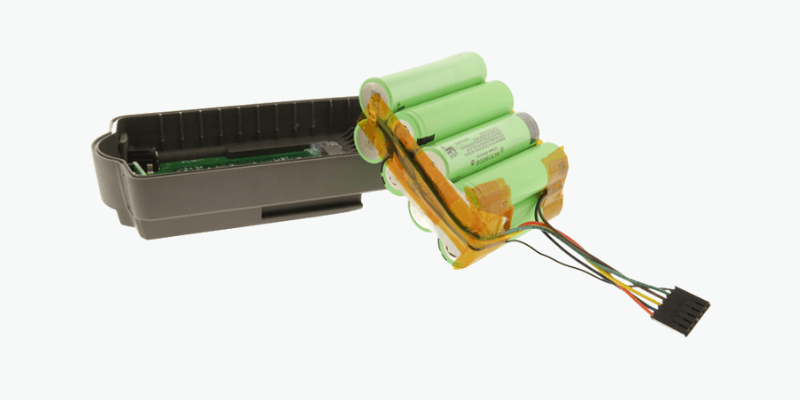

Celdas cilíndricas (p. ej., 18650, 26650, 21700)

Las celdas cilíndricas tienen una fabricación madura, alta energía específica (200-260 Wh/kg), excelente gestión térmica y rentabilidad. Pero su forma rígida limita la densidad de energía volumétrica (500-600 Wh/L) y la flexibilidad del diseño.

La integración de múltiples celdas agrega complejidad y espacio ineficiente. Se utilizan comúnmente en dispositivos médicos portátiles, herramientas comerciales y militares portátiles y herramientas eléctricas.

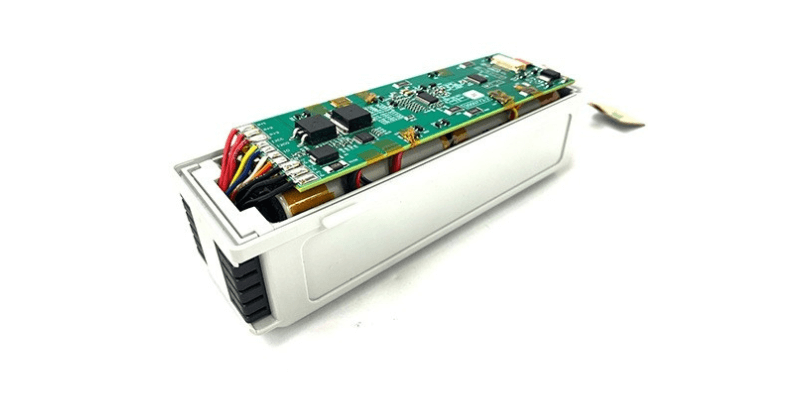

Células prismáticas

Las celdas prismáticas tienen una carcasa rectangular y normalmente ofrecen una mayor densidad de energía volumétrica (600-700 Wh/L) que las celdas cilíndricas debido a una mejor utilización del espacio.

Tienen una flexibilidad de diseño intermedia, pero pueden tener una energía específica ligeramente menor (160-220 Wh/kg) y un costo mayor por kWh. La gestión térmica también puede ser más desafiante.

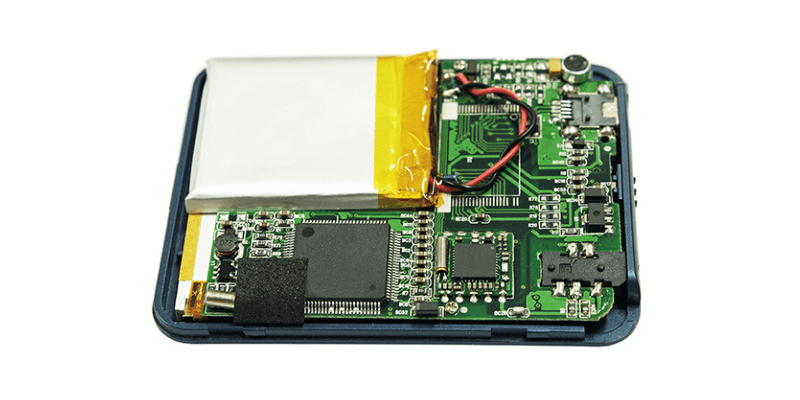

Celdas de polímero (celdas de bolsa)

Las celdas de polímero tienen carcasas laminadas de aluminio flexible y una alta densidad de energía volumétrica (600-800 Wh/L), lo que las hace adecuadas para formas delgadas o irregulares.

Ofrecen una buena relación peso-capacidad (250-300 Wh/kg) pero carecen de rigidez mecánica y necesitan un fuerte soporte estructural.

Los desafíos incluyen la gestión térmica y los costos de fabricación. Estas células se utilizan a menudo en dispositivos portátiles como dispositivos portátiles, equipos médicos, drones, computadoras portátiles y tabletas.

Limitaciones de vatios hora

Un parámetro de diseño clave es la capacidad energética total, medida en vatios-hora (Wh = voltaje * amperios-hora). El aumento de Wh extiende el tiempo de ejecución pero también aumenta el tamaño, el peso y el costo.

Las normas de seguridad imponen límites estrictos a los Wh para viajes aéreos: celdas de menos de 20 Wh y paquetes de baterías Se permiten menos de 100 Wh sin restricciones.

Los paquetes de entre 100 y 160 Wh requieren la aprobación de la aerolínea, con un máximo de dos por pasajero o repuestos. Los paquetes de más de 160 Wh normalmente están prohibidos como equipaje de mano. Estas regulaciones afectan significativamente la energía máxima disponible para ultraportátiles de alto rendimiento como las computadoras portátiles premium.

Opciones de diseño de carga

La carga de baterías de iones de litio requiere parámetros específicos.

A diferencia de otras baterías, necesitan cargadores dedicados debido a las variaciones en el diseño del fabricante que afectan los ajustes de corriente y voltaje.

Con una resistencia más baja, las celdas de iones de litio permiten una carga más rápida, por lo que los cargadores deben entregar la corriente correcta sin sobrecargar ni sobrecargar. Se prefieren los cargadores personalizados para paquetes de baterías específicos a los modelos disponibles en el mercado.

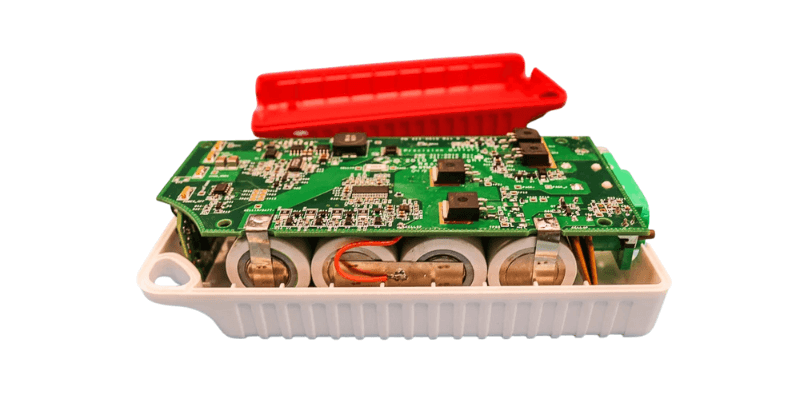

Diseños BMS

Los sistemas de gestión de baterías (BMS) protegen las baterías de iones de litio de problemas como altas temperaturas, sobrecarga, subcarga y fuga térmica. Las regulaciones exigen la instalación de BMS para todos baterías a base de litio, incluidos los dispositivos portátiles.

Para los portátiles, las funciones del BMS incluyen monitoreo de temperatura, gestión de sobrecarga y descarga y diagnóstico de fallas.

La interoperabilidad también es esencial para comunicar el estado de la batería entre redes y sistemas de controlador.

Características especiales del gabinete

La seguridad es crucial para los dispositivos portátiles que utilizan baterías de iones de litio. Estas baterías deben protegerse de pinchazos y daños si el dispositivo se cae o se manipula mal.

La protección de circuitos, como los dispositivos poliméricos de coeficiente de temperatura positivo (PPTC), puede proteger los circuitos durante el envío y el transporte.

Los gabinetes también protegen las baterías de iones de litio de golpes y vibraciones al tiempo que permiten la ventilación del gas y la disipación del calor.

Los fabricantes ofrecen varias opciones de gabinetes, que incluyen envoltura retráctil, plástico formado al vacío y plástico moldeado por inyección, que se someten a pruebas de caída de seguridad para garantizar durabilidad y confiabilidad.

Regulaciones de Portabilidad

Las normas de transporte para baterías de iones de litio se aplican tanto a dispositivos portátiles como a no portátiles.

Todas las baterías de litio deben incluir BMS componentes, ya sea que se envíen por separado o instalados. Están limitados a un máximo de 100 vatios-hora a menos que lo apruebe el transportista. Los dispositivos portátiles requieren pruebas y certificación de seguridad.

A partir de enero de 2026, las baterías de iones de litio enviadas solas deben tener un estado de carga (SoC) del 30 % o menos. Además, el embalaje para envíos sin especificaciones debe cumplir con la prueba de pila de 3,0 metros si contiene baterías dentro o está empaquetado con dispositivos.

Conclusión

El diseño de paquetes de baterías de iones de litio para dispositivos portátiles depende de las necesidades del dispositivo, los estándares de la industria (como los de uso médico o militar) y las regulaciones necesarias. A fabricante de paquetes de baterías personalizados como Holo Battery puede ayudar a determinar la tecnología y las características adecuadas para garantizar que su batería funcione de manera efectiva, siga siendo confiable y segura.