Key Takeaway:

- Selecting a lithium battery pack manufacturer requires a meticulous evaluation of capabilities, quality, compliance, financial stability, and pricing. Prioritize performance, environmental factors, certifications, and a shared vision for a robust partnership.

As demand for lithium-ion batteries grows exponentially, properly selecting a qualified lithium battery pack manufacturer is crucial for companies looking to integrate this core technology.

In this comprehensive guide, we’ll explore the key factors to consider when choosing a lithium-ion battery pack supplier.

Determining Sourcing Requirements

The first step is gaining a clear understanding of your specific lithium-ion battery pack requirements:

- Performance factors – Required capacity, voltage, C-rate, cycle life, acceptable self-discharge

- Physical factors – Desired form factor, size, weight limitations

- Environmental factors – Temperature range, vibration, shock resistance needs

- Quality and reliability – Consistency expectations, defect rates, field failure requirements

- Certification needs – Safety, regulatory, compliance standards like UL 1642 or UN 38.3

- Order quantity – Production scale needs and flexibility

- Cost targets – Pricing requirements and willingness to pay premiums for quality

- Timing – Development timeframes and production ramp rate

Prioritizing your most critical parameters will focus your search only on manufacturers capable of delivering products satisfying your needs.

Assessing Manufacturing Capabilities

Carefully examine potential lithium battery pack manufacturers’ production capabilities:

- Manufacturing capacity – Can they produce sufficient volume to meet current and projected demand? What is their maximum output?

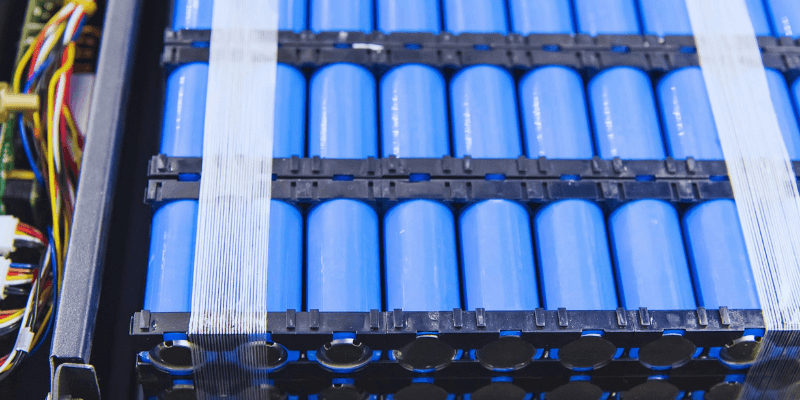

- Cell formats – Do they offer the desired cylindrical, pouch, prismatic, or customized formats?

- Chemistries – Can they supply your preferred lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), lithium nickel cobalt aluminum oxide (NCA) or other cell chemistries?

- Quality processes – What quality control standards and procedures do they implement during manufacturing?

- R&D competence – Do they have strong R&D teams developing next-gen cell technologies? Can they customize cells to your needs?

- In-house vs outsourced – What percentage of production is handled internally vs externally?

- Certifications – Are their facilities and products certified to required standards like ISO 9001, IATF 16949, UL 1642?

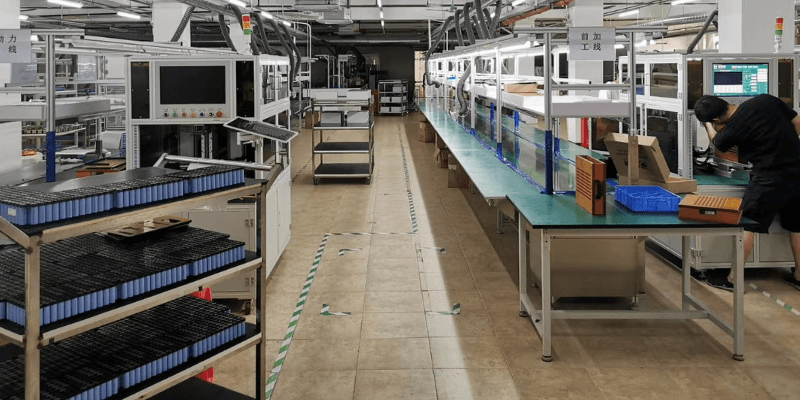

- Automation – What level of automation is used? Higher automation improves consistency.

- Manufacturing locations – Where are their production facilities located? Proximity can aid supply chain logistics.

Opting for manufacturers clearly demonstrating the capabilities to meet your specifications reduces potential delays and issues.

Evaluating Their Industry Experience

The supplier’s directly relevant experience is predictive of their expected performance:

- Years in business – How long have they produced lithium-ion batteries? Longer history reflects stability and knowledge.

- Customer portfolio – Are they supplying lithium-ion batteries or cells to major, reputable OEMs? Large Tier 1 customers indicate trust in the supplier.

- Field failure rate – What is their background defect rate or warranty claims? Lower is better.

- Executive team – Do senior managers have solid background in lithium-ion cell development and manufacturing? Deep expertise improves outcomes.

- Employees – Are staff experienced working specifically on lithium-ion battery lines? Specialized skills are preferred.

- Cycle life testing – Can they thoroughly validate cycle life to benchmark standards for your application?

- Safety testing – Do they perform rigorous testing to certify safety and reliability?

Greater subjected matter expertise makes it more probable a manufacturer will satisfy expectations.

Assessing Responsiveness and Support

The manufacturer’s ability to provide responsive support during development and production is vital:

- Prototype agility – How quickly can they provide functional prototypes or samples?

- Customization – Are they able to customize lithium-ion batteries to meet your exact performance, form factor, or interfacing needs?

- Change accommodation – How readily can they implement product modifications?

- Development support – Will they provide direct engineering support during your product development?

- Post-sale service – Do they have technical staff available for troubleshooting and issue resolution after purchase?

- Quality processes – Can they share detailed defect reduction and corrective action processes?

- Documentation – Will they provide comprehensive cell/pack datasheets, models, qualification reports?

- Business stability – Do they exhibit long-term financial stability?

Choosing a lithium battery producer able to fluidly collaborate with your team enables seamless development and mitigates program disruption.

Auditing Manufacturing Processes and Facilities

Rigorously auditing the manufacturer’s facilities, processes, and management provides assurance of production quality:

- Facility tour – Personally visit factories to inspect infrastructure, cleanliness, and workflow.

- R&D and testing – Review cell design, cycling, safety qualification processes.

- Incoming inspection – Check raw material inspection and acceptance procedures.

- Cell fabrication – Observe electrode coating, winding, stacking, tab welding steps.

- Cell conditioning – Assess initial charge/discharge, aging, and grading processes.

- Quality control – Examine process controls, defect monitoring, and corrective actions.

- Outgoing inspection – Confirm finished pack and cell testing procedures.

- ERP system – Check capabilities for inventory, production scheduling, and traceability.

- Staff competence – Gauge training, technical aptitude, and experience of floor employees.

- Safety standards – Ensure battery manufacturing safety protocols are in place.

Visiting suppliers provides the best appraisal of their consistency and professionalism. Audits build transparency and trust.

Verifying Compliance and Certifications

Confirm all major lithium battery certifications are actively maintained:

- ISO 9001 – Validates quality management system implementation.

- IATF 16949 – Automotive QMS standard indicating robust manufacturing controls.

- ISO 14001 – Confirms environmental management protocols.

- OHSAS 18001 – Demonstrates focus on workplace health and safety.

- EMS 14001 – Verifies environmental monitoring system.

- UL 1642 – Critical safety certification for lithium-ion batteries.

- UN 38.3 – UN Transport testing for safe lithium battery transport.

- RoHS – Confirms restricted hazardous substance compliance.

- REACH – Proves conformity to EU chemicals regulation.

- QC 080000 – Chinese certification covering lithium battery manufacturing.

- RohS / FHSA – Chinese and Korean substance restrictions.

Certifications should be prominently displayed and verifiable through the issuing agency. Validations indicate responsible, high quality manufacturing.

Financial Viability Assessment

The manufacturer must exhibit financial fitness enabling a lasting partnership:

- Credit rating – Favorable third party credit rating showing low bankruptcy risk.

- Financial statements – Review recent income statements, balance sheets, and cash flows.

- Profitability – Prefer consistent gross and net margins over several years.

- Liquidity – Ensure solid liquidity ratios like current ratio and quick ratio.

- Debt levels – Avoid overleveraged companies with excessive long-term debt.

- Forecasts – Do budgets and facilities expansion plans align with your demand expectations?

While challenging for startups, financial stability reduces disruption risk.

Comparing Pricing and Contracts

Battery pricing varies dramatically based on:

- Material costs – Cathode materials like cobalt impact cost significantly.

- Production scale – Large orders receive discounted pricing.

- Customization – Non-standard designs or custom tooling increase cost.

- Geography – Manufacturing country impacts labor and facility expenses.

- Warranties – Longer warranties raise prices.

Require formal long-term agreements with sufficient capacity guarantees. Leverage larger purchase quantities for discounted pricing.

The Ideal Lithium Battery Pack Manufacturer

The optimal lithium battery pack partner will demonstrate strengths in these key areas:

- Manufacturing capabilities and capacity – Producing components matching specifications at required volumes.

- Technology leadership and expertise – Developing and producing advanced lithium-ion batteries through specialized staff.

- Responsiveness and support – Delivering high touch partnership across development, production, and post-sale.

- Quality processes – Utilizing stringent process controls and defect prevention.

- Compliance and safety – Maintaining up-to-date critical safety and regulatory certifications.

- Financial fitness – Exhibiting sales growth, profitability, and access to capital.

- Competitive pricing – Offering cost-competitive pricing aligned with order volumes.

By taking this rigorous approach to evaluating lithium battery manufacturers, you can establish a robust supply chain delivering top quality cells and battery packs optimized to your product and business requirements.

The time invested in properly vetting and selecting lithium-ion battery pack manufacturers will pay dividends through accelerated development, reduced defects, and accelerated speed to market. Leverage this guide as a framework when making one of the most crucial supplier decisions for enabling your lithium-ion battery-powered products.

Related Articles: