Setelah menyelesaikan lebih dari 6.000 Proyek Paket Baterai Lithium Kustom, kami menemukan bahwa klien sering memiliki pertanyaan spesifik. Dalam artikel ini, kami akan mempelajari pertanyaan dan jawaban penting tentang Merancang dan memproduksi paket baterai lithium-ion.

Apa faktor utama yang perlu dipertimbangkan saat memilih paket baterai lithium-ion khusus?

Saat memilih paket baterai lithium-ion khusus, penting untuk mempertimbangkan beberapa faktor kunci.

Pertama, kepadatan energi Memainkan peran penting, karena pelanggan sering mencari baterai lithium-ion untuk aplikasi portabel, menginginkan kapasitas energi tinggi dalam desain yang ringkas dan ringan.

Selain itu, tingkat pembuangan harus diperhitungkan. Ada dua jenis utama sel lithium-ion – sel energi dan sel daya. Sel energi menawarkan kepadatan energi yang tinggi namun penyaluran arusnya lebih rendah, sehingga menghasilkan waktu pengoperasian yang lebih lama, sedangkan sel daya memberikan keluaran arus tinggi yang cepat dengan kepadatan energi yang lebih rendah.

Siklus hidup adalah aspek penting lainnya yang perlu dipertimbangkan. Sel litium-ion fosfat, meskipun berpotensi lebih berat, dapat menghasilkan lebih dari 3.000 siklus, melampaui 500-600 siklus jenis lainnya.

Keselamatan adalah hal yang terpenting untuk semua baterai litium-ion, dengan sel litium-ion fosfat yang dikenal karena ketahanannya yang lebih baik dalam hal fitur keselamatan.

Selain itu, toleransi suhu merupakan pertimbangan penting. Meskipun baterai lithium sebelumnya terbatas pada aplikasi suhu tinggi, kemajuan kini memungkinkan penggunaannya dalam berbagai pengaturan dengan suhu tinggi.

Bagaimana Manajemen Termal Dapat Diintegrasikan ke dalam Paket Lithium Khusus?

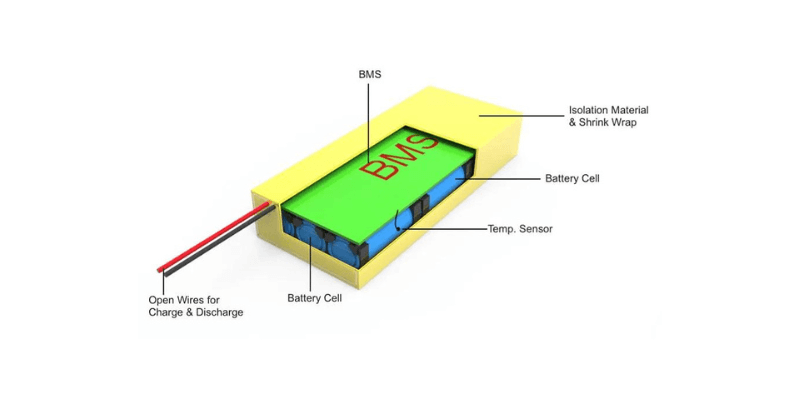

Wadah yang lebih besar sering kali dapat menghilangkan panas dengan lebih baik, dan terkadang kami menambahkan penyebar panas dalam kemasan untuk mengelola kelebihan panas.

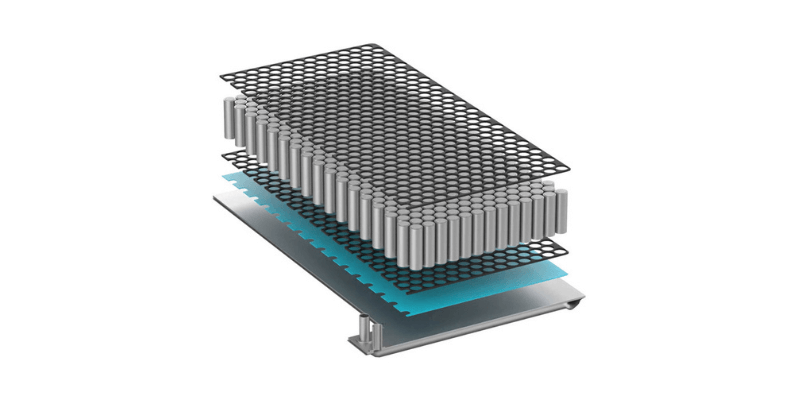

Pendekatan Tesla terhadap pendinginan aktif menetapkan standar tinggi dalam industri, menggunakan sirkulasi cairan di sekitar sel individual untuk menjaga suhu seragam dan menghilangkan gradien termal. Sistem canggih ini memastikan sel-sel internal sesuai dengan suhu sel-sel eksternal, bahkan memungkinkan pemanasan awal pada hari-hari dingin untuk meningkatkan efisiensi dan umur panjang.

Jika keterbatasan anggaran membatasi pilihan pendinginan, memanfaatkan sensor suhu dapat menjadi solusi hemat biaya. Sensor ini dapat memantau variasi suhu dan menyesuaikan pengoperasian perangkat, seperti membatasi prosesor atau menyesuaikan kecepatan motor untuk mencegah panas berlebih.

Selain itu, penerapan sistem peringatan pada baterai dapat membantu mengingatkan pengguna akan potensi masalah suhu dan mengambil tindakan pencegahan secara efektif.

Fitur Keamanan Kurang Umum Apa yang Harus Disertakan Dalam Baterai Lithium Khusus?

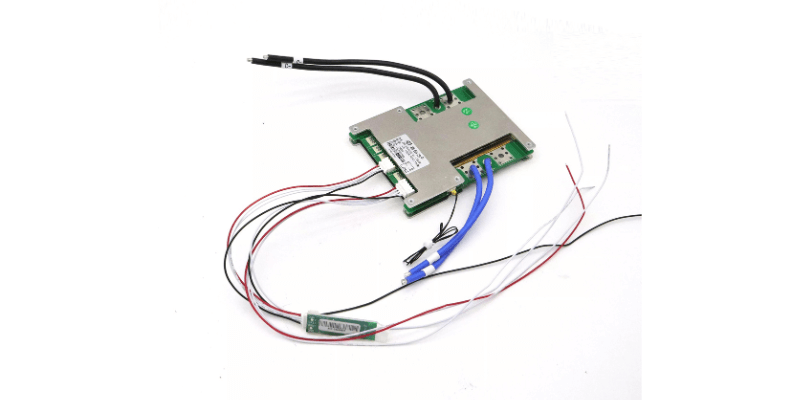

Fitur keselamatan tingkat kedua dan ketiga sering kali luput dari perhatian, namun ada satu aspek penting yang tetap diperhatikan penyeimbangan sel.

Banyak orang melihatnya sebagai fitur siklus hidup, mirip dengan mengisi nampan es batu secara merata untuk memastikan semua sel mempertahankan tingkat yang sama. Keseimbangan ini memperpanjang masa pakai paket dan mencegah sel-sel individual jatuh terlalu rendah atau naik terlalu tinggi, yang dapat memicu sirkuit keselamatan dan mengurangi persepsi runtime.

Selain itu, jika sirkuit keselamatan tidak berfungsi, pergerakan rendah atau tinggi yang terus-menerus dapat menyebabkan pertumbuhan dendrit atau masalah dengan pemisahan material, yang berpotensi menyebabkan korsleting internal. Jadi, penyeimbangan sel memang merupakan fitur keamanan.

Pertimbangan lain termasuk merangkum baterai dengan katup pelepas tekanan yang efektif. Hal ini dapat membantu mengurangi risiko tekanan berlebih pada baterai, terutama saat pengisian cepat atau jika terjadi kegagalan fungsi.

Terakhir, penggunaan bahan tahan api yang memiliki rating suhu tinggi dapat memastikan hal tersebut komponen jangan menyala selama situasi kegagalan. Fitur keselamatan yang kurang dikenal ini memainkan peran penting dalam kinerja dan keandalan baterai.

Apakah Sebagian Besar Standar Produk Akhir Mengharuskan Baterai Memenuhi Standar Tertentu?

Ya, sebagian besar standar produk akhir mengamanatkan bahwa baterai memenuhi kriteria keselamatan, kinerja, dan kualitas tertentu untuk memastikan keselamatan konsumen dan keandalan produk. Badan pengatur menerapkan standar ini untuk memitigasi risiko seperti bahaya kebakaran, pelarian termal, dan dampak lingkungan.

Standar utama meliputi:

- DAN 38.3: Meliputi persyaratan pengujian untuk pengangkutan baterai lithium yang aman.

- IEC 62133: Menentukan persyaratan keselamatan untuk baterai litium ion pada perangkat elektronik portabel.

- IEC 62619: Berfokus pada keamanan sel-sel ion lithium sekunder dan baterai dalam aplikasi industri.

- UL1642 dan UL 2054: Standar Keselamatan untuk Baterai Lithium dalam Penggunaan Rumah Tangga dan Industri.

- Penandaan CE: Menunjukkan kesesuaian dengan standar keselamatan UE.

Kepatuhan diperlukan untuk mencegah penarikan, kewajiban hukum, dan kerusakan pada reputasi merek; Produsen harus mematuhi standar ini untuk memberikan produk bertenaga baterai yang aman.

Apakah Anda memiliki rekomendasi untuk menemukan sel online untuk pembuatan in-house? Apakah sesederhana menggunakan Google untuk menemukan opsi yang memenuhi persyaratan saya?

Meskipun Google dapat menjadi titik awal, berikut adalah rekomendasi untuk menemukan pemasok sel yang andal:

- Bermitra dengan Pemasok terkemuka yang dikenal dengan sel baterai berkualitas dan dukungan yang dapat diandalkan.

- Konfirmasikan spesifikasi yang jelas, termasuk voltase, kapasitas, kepadatan energi, siklus hidup, ukuran, berat, dan fitur keselamatan untuk mempersempit pencarian Anda.

- Pastikan kompatibilitas dengan sistem Anda dengan mempertimbangkan kesesuaian mekanis, sambungan listrik, dan protokol pengisian/pengosongan untuk menghindari masalah integrasi selama produksi.

- Pilih sel yang memenuhi standar industri yang diakui seperti UL atau IEC untuk keselamatan dan kinerja; meninjau lembar data produk atau laporan pengujian dari pemasok.

- Konsultasikan dengan pakar industri, insinyur, atau konsultan yang berpengalaman dalam mencari sumber sel baterai untuk manufaktur. Mereka dapat memandu Anda dalam memilih sel yang tepat untuk kebutuhan spesifik Anda.

- Evaluasi logistik pengiriman mengenai opsi, waktu tunggu, biaya, dan persyaratan pengiriman.

Bagaimana Anda Menentukan Siklus Hidup Suatu Produk?

Umumnya, menentukan masa pakai baterai melibatkan beberapa metode:

- Spesifikasi Pabrikan: Periksa perkiraan umur siklus pabrikan, yang sering kali didasarkan pada pengujian standar. Namun, nilai-nilai ini biasanya mencerminkan arus kondisi tunak yang rendah.

- Tes Penuaan yang Dipercepat: Lakukan pengujian dalam kondisi terkendali dengan mengisi dan mengosongkan baterai berulang kali sambil memantau penurunan kinerja dan kapasitas. Metode ini memperkirakan berapa banyak siklus yang dapat ditahan baterai sebelum mencapai ambang batas kapasitas tertentu (misalnya, 80% dari kapasitas aslinya).

- Data dan Pengalaman Masa Lalu: Data historis mengenai baterai serupa dapat memberikan wawasan tentang siklus hidup yang diharapkan melalui penelitian industri dan studi kasus, meskipun metode ini menawarkan perkiraan kasar.

- Kimia dan Desain Baterai: Kimia yang berbeda memiliki karakteristik siklus hidup yang berbeda-beda; memahami ini bersama dengan faktor desain seperti elektroda bahan dapat memberikan perkiraan kasar kinerja.

- Kondisi Operasional: Faktor-faktor seperti laju pelepasan, kedalaman pelepasan (DOD), protokol pengisian daya, dan kondisi lingkungan secara signifikan memengaruhi siklus hidup.

Meskipun metode ini memberikan perkiraan kasar, pengujian sebenarnya yang disesuaikan dengan kondisi tertentu adalah cara paling andal untuk menentukan masa pakai baterai, terutama untuk produk luar ruangan yang mengalami suhu ekstrem.