重要なポイント:

- 保護委員会とBMSの重要性: リチウムバッテリーの安全性、過充電、過剰充電、および熱暴走の防止に不可欠です。

- 重要なコンポーネント: 保護板は、監視と制御用のICS、現在の管理用のMOSFET、および安定化のためのコンデンサや抵抗器などの追加コンポーネントで構成されています。

- BMS対保護委員会: BMSは、高電圧や大きなバッテリーパックに適したセルバランスや通信インターフェイスなどの高度な機能を提供します。

- 選択要因: 保護ボードを選択する際には、バッテリーパックのサイズ、電圧、化学、AH評価、アプリケーション、および動作環境を検討してください。

- カスタマイズされた保護板: 最適化されたパフォーマンスと安全性のために、特定のバッテリーとデバイスの要件に一致するテーラードソリューションを提供します。

- 安全認定: UN/DOT 38.3、IEC 62133、UL 2054、UL 2580、CEマークなどの基準を使用して、製品の安全性、市場性、規制のコンプライアンス、および消費者の信頼を確保するために重要です。

エネルギー密度が高いため、 リチウム電池 さまざまな電子機器やアプリケーションの理想的な電源になっています。ただし、リチウム電池の化学的特性も特定の安全上の危険を引き起こします。過充電、過充電、高電流の排出などの問題は、バッテリーの損傷、寿命の短縮、さらには安全事故につながる可能性があります。

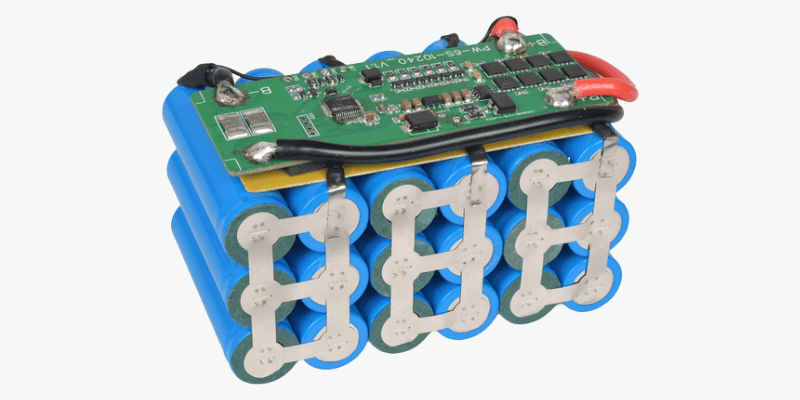

このような発生を防ぐために、リチウムバッテリー保護板が生まれました。これらのボードは、低電圧リチウム電池の監視および保護機能を提供するように設計されています。高電圧リチウム電池の場合、より包括的 バッテリー管理システム (BMS) 通常、バッテリーパックのより微妙で包括的な監視を提供することができます。

主な部品 & 保護ボードの機能

サイズは小さくなっていますが、保護ボードの内部構造と機能は非常に洗練されており、複雑です。これは主に次の重要なコンポーネントで構成されており、それぞれがバッテリーの安全性を保護する上で不可欠な役割を果たしています。

統合回路(ICS)の役割

統合サーキット(ICS)は、すべてのバッテリー保護機能の処理と制御を担当する保護ボードの脳として機能します。組み込みプログラムとアルゴリズムを通じて、バッテリーの電圧、電流、および温度パラメーターをリアルタイムで監視します。

これらのパラメーターがプリセットの安全性のしきい値を超えると、ICはすぐにコマンドを発行して、潜在的な損傷を防ぐためにバッテリーの動作状態を調整または遮断します。

ICの効率と精度は、保護システムの全体的な有効性と信頼性に直接関連しています。

スイッチングコンポーネント(MOSFETなど)の重要性

MOSFETS(金属酸化物 - 陰導体フィールド効果トランジスタ)は、保護ボードのスイッチングコンポーネントです。 IC命令に従って、バッテリーの充電と放電経路を制御します。

過充電、過剰充電、またはその他の異常な条件が検出されると、MOSFETは電流を急速に遮断して、バッテリーの損傷を防ぐことができます。

MOSFETの高速応答能力は、予期しない状況からバッテリーを保護する上で最も重要です。

他の重要なコンポーネント(コンデンサ、抵抗器など)の関数

ICSとMOSFETを超えて、保護板には、コンデンサや抵抗器などの追加の電子コンポーネントが装備されています。

コンデンサは、電源を安定化し、電圧の変動を減らし、突然の高電圧ショックまたは低電圧ショックからバッテリーを保護することを担当しています。

電流を調整するために抵抗器が使用され、バッテリーが安全な電流範囲内で動作するようにします。

BMSと保護委員会の違い

BMSと保護ボードはどちらもバッテリーの安全性とパフォーマンス管理に関連していますが、機能性と複雑さは大きく異なります。

BMSの定義と高度な機能

BMSは複雑な電子システムです。過剰充電、過剰充電、過熱、短絡保護など、保護ボードの基本的な機能が含まれるだけでなく、より高度な機能を統合します。

- BMSは、電圧、電流、温度、充電ステータス、および各セルのステータスなど、バッテリーのステータスをリアルタイムで確認できます。

- それは促進します バッテリーバランス、パック内のすべてのセルが同じ速度で充電されて放電することを保証し、それによりバッテリーパック全体の寿命を延ばします。

- BMSには、外部デバイス(充電器、監視システム、その他の電子デバイスなど)とのデータ交換を可能にする通信インターフェイスが装備されており、より高度なバッテリー管理と診断を可能にします。

保護ボードを選択する際に考慮すべき要因

適切なリチウムバッテリー保護ボードを探しているとき、バッテリーの安全性と効率を保証するために考慮すべきいくつかの重要な要因があります。選択プロセス中に注意を払わなければならない3つの領域があります。

バッテリーパックのサイズと電圧

サイズと バッテリーパックの電圧 保護ボードを選択するための基礎パラメーターです。

さまざまなバッテリーパックにはさまざまなサイズと電圧要件があり、保護ボードはこれらの特性と互換性がなければなりません。

たとえば、小さなバッテリーパックにはコンパクトな保護ボードが必要になる場合がありますが、高電圧バッテリーパックでは、高電圧を処理できる保護ボードが必要です。

バッテリーの化学的性質とAH(アンペア時間)評価

バッテリーの化学とアンペア時間の評価により、エネルギー容量と排出特性が決まります。異なる化学的特性には、さまざまな保護戦略と技術が必要になる場合があります。

たとえば、特定の化学的特性を持つバッテリーは温度変化に対してより敏感である可能性がありますが、他のバッテリーはより正確な充電制御を必要とする場合があります。 AH定格が高いバッテリーは、退院中により多くの電流を放出するため、より高い電流レベルを処理できる保護ボードが必要です。

バッテリーパックの使用および動作環境

バッテリーパックのアプリケーションシナリオと作業環境は、パフォーマンスと保護要件に大きな影響を与えます。

たとえば、バッテリーパックが屋外機器用に運命づけられている場合、保護委員会は、高温、低温、湿度などの厳しい気象条件に耐えることができる必要があります。

同様に、バッテリーパックを高い振動または衝撃のある環境に展開する場合、保護ボードは、そのような外部ストレッサーに耐えるために堅牢性と回復力を示しなければなりません。

特定のアプリケーションに基づいて保護ボードを選択する方法

さまざまなアプリケーションシナリオの保護ボードを選択するためのいくつかのガイドラインを次に示します。

さまざまなデバイスによる保護板の特別な要件

- ポータブル電子デバイス: スマートフォンやラップトップなどのポータブルデバイスの場合、保護ボードはコンパクトで効率的である必要があります。これらのデバイスは通常、バッテリーが光負荷の下で動作するために動作する必要があるため、保護ボードには、頻繁な充電と放電のニーズに適応するために、正確な電流制御と迅速な応答能力が必要です。

- 電気自動車: 自動車や電気自転車などの電気自動車には、バッテリーの安定性と耐久性に関する要件があります。保護ボードは、より大きな電流と電圧の変動を処理できるだけでなく、運転中に遭遇する可能性のあるさまざまな状況に対処するために、過熱および短絡保護機能を備えている必要があります。

- エネルギー貯蔵システム: 住宅または産業のエネルギー貯蔵システムは、多くの場合、長期にわたってバッテリーを安定に動作させる必要があります。保護委員会には、長期の安定した監視機能、およびバッテリーの健康を評価して、長期充電および放電サイクル中に最適なパフォーマンスを確保する機能が必要です。

特定のアプリケーションの保護委員会を選択するためのガイドライン

- アプリケーションのニーズを評価します: まず、アプリケーションの特定のニーズに基づいて、BMSまたは保護委員会を選択するかどうかを決定する必要があります。アプリケーションが高度なバッテリー管理と監視機能を必要とする場合、またはバッテリーパックが大きい場合は、BMSがより良い選択かもしれません。

- コスト要因を考慮してください: BMSは通常、より多くの機能とより複雑さを提供するため、保護ボードよりも高価です。予算の制約が要因であり、アプリケーションが高度な機能を要求しない場合、保護委員会はより適切なソリューションを提示する場合があります。

- 技術的な能力を考慮してください: BMSを選択するには、より複雑なバッテリー管理の問題を処理する技術的な能力が必要です。チームまたは組織にそのような技術的能力がある場合、BMSはより柔軟性と制御を提供できます。

- 規制と基準: 特定の産業または地域には、BMSの使用を必要とする特定の規制または基準がある場合があります。そのような場合、BMSを選択することは、技術的な決定だけでなく、規制に準拠する必要もあります。

カスタマイズされた保護ボードの利点

多くの場合、標準の保護板は、特定のバッテリーやデバイスのニーズを完全に満たしていない場合があります。これは、カスタマイズされた保護ボードが出てくる場所です。カスタマイズされた保護ボードは、さまざまな利点を提供し、多くのアプリケーションに理想的な選択肢となっています。

カスタマイズされた保護ボードの価値

- 要件の正確な一致: カスタマイズされた保護ボードは、バッテリーの特定の化学、電圧、容量、サイズに基づいて設計でき、バッテリーの最高のパフォーマンスと最長の寿命を確保できます。

- 強化された機能: カスタムテイアル保護板は、バッテリーのバランス、高度な監視、リモート障害診断などの追加機能を統合するために作成されています。

- 互換性の向上: カスタマイズされた保護ボードは、既存のBMSまたは他の電子コンポーネントとシームレスに統合され、システム全体の互換性と効率を高めることができます。

- 最適化されたパフォーマンス: 特定のアプリケーションを最適化することにより、カスタマイズされた保護ボードは、バッテリーの充電と放電効率を改善し、エネルギーの損失を減らし、それによってデバイスの使用時間を延長することができます。

カスタマイズされた保護ボードを選択することにより、システム全体の安全性と信頼性を高めながら、さまざまなアプリケーションでバッテリーパックが最適に機能することを確認できます。カスタマイズされた保護ボードは、初期段階でより多くの時間とリソースを必要とする場合がありますが、バッテリーのパフォーマンスと安全性にもたらす改善は、長期的には価値があります。

保護委員会の安全性と認証

安全性は、リチウムバッテリー保護ボードを選択する際の最も重要な考慮事項の1つです。

保護委員会の安全性は、バッテリーの寿命と効率だけでなく、ユーザーの幸福にも関連しています。保護委員会の安全性を保証するには、一連の安全認定を受ける必要があります。

安全認証の重要性

- ユーザーの幸福を確保する: 安全性認定により、保護委員会は、設計および製造プロセス中に厳格な安全基準を満たし、それにより使用中のリスクを軽減することが保証されます。

- 市場の地位の強化: 認定された保護委員会は、消費者と業界によってより簡単に認識されるため、製品の市場の存在を増幅します。

- 規制要件の遵守: 多くの国や地域では、バッテリー製品は、合法的に販売および輸送されるために特定の安全認定を通過する必要があります。これらの規制の遵守は、企業の法的責任です。

- 消費者の信頼を高める: 権威ある認定を備えた保護委員会は、消費者を強化することができます’ 製品の品質と安全性に対する信頼、製品の販売の促進。

リチウムバッテリー保護板の一般的な認証基準

- および/与える38.3: 世界的に認識されているこの標準には、身体的虐待などのさまざまな厳格なテストが含まれています。 サーマル バッテリーのテスト、振動テスト。

- IEC 62133: 国際電気技術委員会によって設立されたこの標準は、リチウムバッテリーとバッテリーシステムの安全要件の概要を示しており、設計、テスト、認証の側面をカバーしています。

- UL 2054: これは、アメリカの安全認証機関ULが設定したリチウムバッテリーパックとバッテリーパック保護板の安全基準であり、バッテリーパックの防火と安全性能に焦点を当てています。

- UL 2580:この標準は、機械的、電気的、および熱安全性試験を含む電気自動車で使用されるリチウム電池の安全要件に合わせて調整されています。

- CEマーキング: これは、欧州経済領域内の安全認証マークであり、製品がEUの安全性、健康、環境保護の要件に準拠していることを示しています。

結論

リチウムバッテリー保護ボードの選択は、バッテリーの機能、使用の要件、および安全認定の順守を徹底的に分析する必要がある重要なタスクです。

これらの要素を慎重に計量することにより、バッテリーの安全性と寿命の両方を高める知識豊富な選択をすることができます。これにより、最終的にシステム全体の信頼性とパフォーマンスが向上します。

関連記事: