Key Takeaways:

- Importance of Terminals: Proper battery terminals ensure optimal performance and longevity by facilitating secure electrical connections.

- Types of Terminals: Button/flat, stud, and bolt/clamp terminals each have unique benefits for different applications.

- Maintenance Best Practices: Regular cleaning, proper installation, and routine inspections are crucial for terminal upkeep.

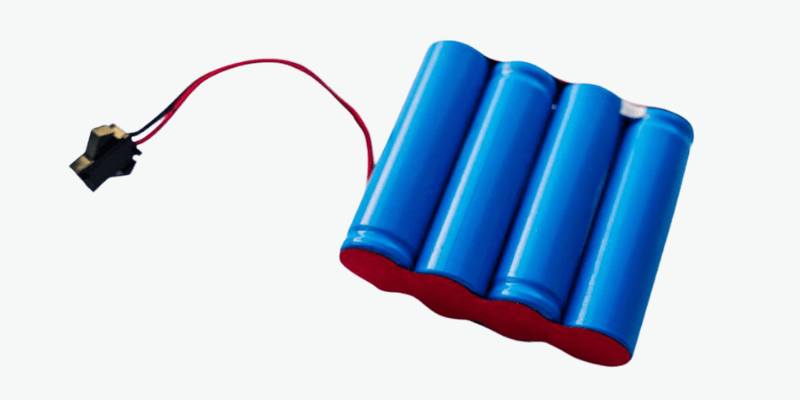

Lithium battery terminals are critical for optimal performance and longevity. This comprehensive guide covers everything you need to know about lithium battery terminals, from key types and proper maintenance to mistakes to avoid.

Follow these best practices for lithium battery terminals and your batteries will deliver reliable power for years to come.

What are Battery Terminals and Why They Matter

Battery terminals are the metal tabs or connectors attached to the ends of a battery. Their purpose is to allow secure physical and electrical connections for charging and discharging the battery.

Proper battery terminal connections are extremely important for several reasons:

- Battery terminals facilitate the flow of energy in and out of the cells. Poor connections can lead to reduced current flow.

- Secure terminals prevent intermittent electrical connections as devices are moved or vibrated. Loose terminals can cause sudden power loss.

- Corrosion-resistant terminals sustain optimal contact over time. Corroded terminals increase resistance and impair battery performance.

- Sturdy, durable terminals withstand repeated cycles of charging and discharging without failure. Weak terminals are prone to breaking.

By ensuring proper installation and maintenance of battery terminals, users can optimize battery lifespan and performance. Battery terminals may be small components, but they play an outsized role in battery function.

Types of Lithium Battery Terminals

Lithium battery terminals come in various shapes and styles, each with their own set of advantages and ideal use cases. The three main types of lithium battery terminals are:

Button/Flat Terminals

This basic flat tab design is the most cost-effective and space-efficient terminal type. Flat terminals offer straightforward connectivity through simple soldering, welding, or hardware attachments.

However, the limited contact surface area can lead to comparatively higher electrical resistance and more heat generation. This style is best suited for low-drain batteries where maximum conductivity is not essential.

Stud Terminals

Stud terminals improve conductivity by using a protruding round threaded post attached to the battery surface. This allows for secure connections with plenty of adjustable contact area for very low resistance.

Studs provide versatile connectivity but occupy a larger footprint vs flat terminals. They also allow the use of multiple fasteners like washers and nuts to fine-tune the connection.

Stud terminals are a great choice for high-drain applications.

Bolt/Clamp Terminals

If robust physical connections are the top priority, bolt or clamp terminals are ideal. These use bolts or clamps integrated into the terminal design to form an extremely rugged, vibration-resistant connection.

However, they do require more complex installation procedures than simpler terminal types. Bolt/clamp terminals are popular in electric vehicle batteries where resilience is key.

Comparing the Tradeoffs

In summary, with flat terminals, you trade off some conductivity for compactness and cost savings. Stud terminals offer maximum conductivity in a more adjustable package. And bolt/clamp terminals prioritize ultra-secure physical connections above all. Consider the performance needs, available space, installation process, and cost sensitivities when selecting lithium battery terminals.

The right terminal provides secure electrical and mechanical connectivity over thousands of battery cycles.

Connecting the Battery Terminals

Connecting lithium battery terminals properly is vital for optimal performance. There are a few key steps in the process:

Methods of Connecting Terminals to Battery Cells

Terminals must form high-conductivity connections to the internal battery cell electrodes. Common methods include:

- Welding: Small spot welds fuse the terminal to the cell. Requires precision but creates durable connectivity.

- Soldering: Soldering also adheres the terminal to the cell plate. Allows for broader attachment area.

- Mechanical fastening: Screws, clamps and rivets can mechanically bind the terminal to the cell. Offers more adjustment.

Connecting Terminals to Devices or Chargers

External connections complete the electric circuit to utilize the battery’s power capacity:

- Direct wiring permanently connects devices through soldered wires or fixed terminals.

- Plugs/sockets allow swappable connectivity between removable batteries and devices.

- Fasteners like screw lugs create adjustable external terminal connections.

Ensuring Clean and Secure Connections

Proper installation results in:

- Low contact resistance for unimpeded current flow.

- Resistance to vibration and shocks that can disturb connections.

- Corrosion prevention through protective coatings on terminals.

- Damage avoidance by avoiding overtightening fasteners.

Robust connections during installation and throughout battery life are essential.

Maintaining Proper Terminal Connections

Proper terminal maintenance is key to maximizing battery lifespan. Here are tips for upkeep:

Signs of Loose or Damaged Terminals

Look for:

- Excess wobble or movement

- Visible cracks/breakage

- Corrosion like rust or green oxidation

- Burnt or melted plastic housing

Use a voltmeter to check for abnormally high resistance.

Consequences of Loose Terminals

Loose battery terminals can lead to:

- Intermittent power loss as contact is disrupted

- Reduced current flow due to increased resistance

- Faster draining of batteries

- Complete failure to power devices

Fixing Bad Connections and Replacing Terminals

Options to restore terminals include:

- Cleaning corrosion with baking soda/water mix

- Sanding rough texture to expose fresh metal

- Retightening loose fasteners to reduce movement

- Soldering/welding to rebuild broken connections

- Complete terminal replacement if damage is too severe

Routine inspection and maintenance preserves performance.

Key Differences Between Terminals and Lugs

There are some important distinctions between terminals and lugs:

Definition of Battery Lugs vs. Terminals

- Terminal – The metal tab welded to the battery itself.

- Lug – An external connector that attaches to the terminal.

When to Use Lugs – The Pros and Cons

Pros of lugs:

- Allow for flexible positioning of cable connections

- Enable multiple devices to attach to one terminal

- Protect terminals from stress/damage from cables

Cons of lugs:

- Additional connection point can loosen over time

- Require careful sizing to match terminals

- Added cost compared to direct terminal connections

Lugs are useful for creating adjustable, removable links to terminals, but direct connections are most robust.

Proper Installation and Maintenance

Following best practices for installing and maintaining terminals ensures longevity:

Best Practices for Installation and Replacement

- Use manufacturer recommended torques when tightening fastener hardware. Avoid over-tightening.

- Apply dielectric grease on connections to prevent corrosion.

- Inspect the battery casing for cracks near terminals – structural weaknesses can loosen terminals prematurely.

- When replacing terminals, select the proper size and type for the battery specifications.

Preventing Corrosion and Heat Damage

- Use terminal hardware designed for high temperatures like nickel-plated steel.

- Insulate terminals from each other using non-conductive shrouds. This prevents shorts.

- Clean terminals periodically using a wire brush to remove any buildup.

Cost Overview for Replacing Terminals

- Button or flat terminals: $1-$10 per terminal

- Threaded stud terminals: $5-$20 per terminal

- Labor costs vary based on project complexity.

Routine maintenance keeps terminals working optimally for years.

Conclusion

Battery terminals may not be the most exciting battery component, but they play an outsized role in enabling lithium batteries to deliver reliable, efficient power output. Proper terminal selection, installation, and maintenance fundamentally supports battery functionality and longevity.

By understanding the different types of terminals and how to connect them robustly, battery users can optimize performance. Well-connected terminals allow batteries to charge and discharge smoothly over thousands of cycles.

With the right terminal know-how, you can ensure your lithium batteries live up to their full potential and exceed expectations. Thanks for taking the time to learn about these small but critical pieces that power our modern battery-driven lives!