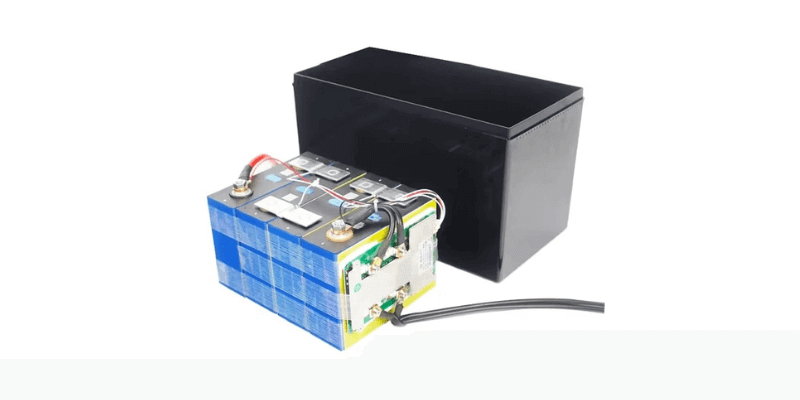

Erstellen eines maßgeschneiderter Akku Dabei geht es darum, die richtige Balance zwischen Leistung, Sicherheit und Einhaltung von Industriestandards zu finden. Hier finden Sie eine Aufschlüsselung der wichtigsten Überlegungen sowie Insidertipps zur Unterstützung von Ingenieuren und Produktentwicklern.

Ermittlung des Leistungsbedarfs

Wenn es um den Strombedarf geht, bestimmen sie im Wesentlichen a Spannung der Batterie, Kapazität und Energiedichte. Folgendes müssen Sie beachten:

Anwendungsspezifische Belastungen

Unterschiedliche Anwendungen haben unterschiedliche Anforderungen. Elektrofahrzeuge (EVs) erfordern beispielsweise eine hohe Leistungsdichte (denken Sie an Entladeraten von 50 °C), während bei medizinischen Geräten der Schwerpunkt auf der Aufrechterhaltung einer konstanten Spannung liegt.

Spannungsanpassung

Kundenspezifische Akkupacks kombinieren oft Zellen in Serie oder parallel Setups. Ein 48-V-System könnte also etwa 13–14 LiFePO4-Zellen mit jeweils 3,2 V oder 14 NMC-Zellen mit jeweils 3,7 V verwenden.

Optimierung der Energiedichte

Wenn Sie die Packungsgröße mit Zellen mit hoher Kapazität (bis zu 40 Ah pro Zelle) reduzieren möchten, denken Sie daran, dass Sie fortgeschrittene Zellen benötigen Thermalmanagement.

Spitzenleistung vs. Dauerleistung

Hoch Kiste Zellen (wie solche bei 50 °C) sind ideal für Drohnen, die schnelle Energieschübe benötigen, während Energiespeichersysteme dauerhafte Leistung gegenüber kurzen Energieschüben priorisieren.

Berechnung des Gebührenbedarfs

Ladeparameter beeinflussen maßgeblich die Effizienz und Sicherheit des Ladens. Hier ist die Übersicht:

Ladeprotokolle

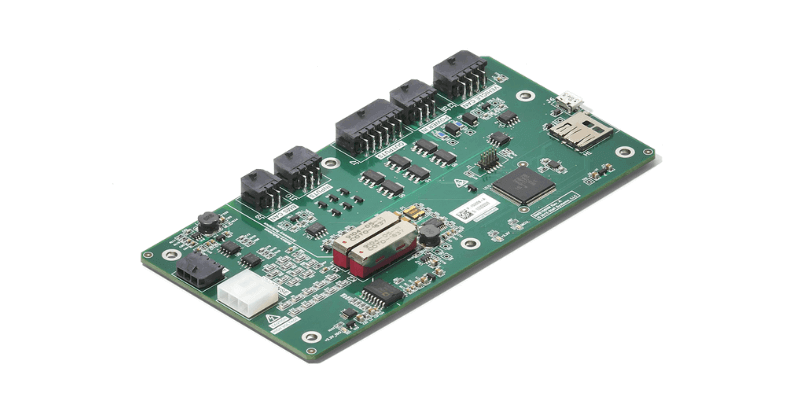

Für Schnellladesysteme wie 800-V-Setups ist Ihr Batteriemanagementsystem (BMS) muss Kommunikationsprotokolle wie CAN oder SMBus beherrschen.

Gebührensatz

Es ist wichtig, die Belastbarkeit Ihrer Zellen nicht zu überschreiten, z. B. bei 1 °C für LiFePO4-Zellen oder bei 0,5 °C für einige NMC-Zellen.

Thermische Einschränkungen

Schnelles Laden erzeugt mehr Wärme, daher ist die Verwendung von Flüssigkeitskühlung oder Phasenwechselmaterialien unerlässlich, um die Temperaturen unter 45 °C zu halten.

Bereitstellung von Sicherheitsfunktionen

Sicherheit ist unerlässlich, ohne Kompromisse. Hier sind die wichtigsten Sicherheitsmerkmale, die Sie berücksichtigen sollten:

BMS-Schutzschichten

- Überspannungs-/Unterspannungsabschaltungen (z. B. maximal 3,65 V für LiFePO4).

- Schnelle Kurzschlusserkennung (weniger als 1 ms Reaktionszeit).

- Zellausgleich, ob passiv oder aktiv, um gleichmäßige Spannungsniveaus aufrechtzuerhalten.

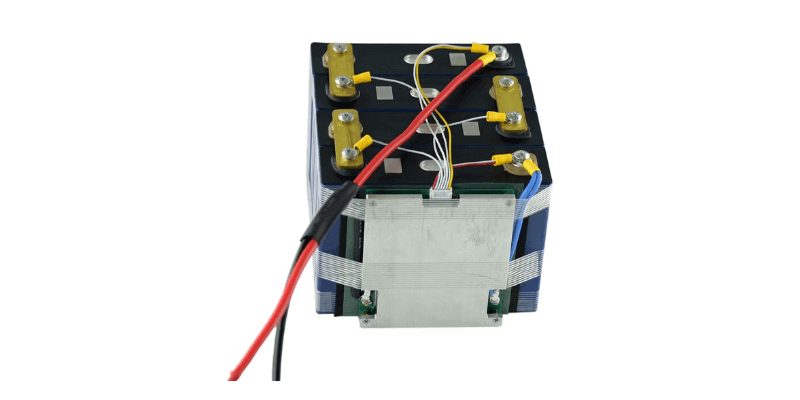

Wärmemanagement

- Flüssigkeitskühlung für Hochleistungspakete wie EV-Batterien.

- Selbsterwärmungstechnologie sorgt für einen reibungslosen Betrieb bei Kälte.

Mechanische Sicherheit

- Gehäuse mit Schutzart IP67 zum Schutz vor Staub und Wasser.

- Explosionsentlüftungsöffnungen und flammhemmende Materialien, wie z. B. Kunststoffe mit UL94 V0-Einstufung.

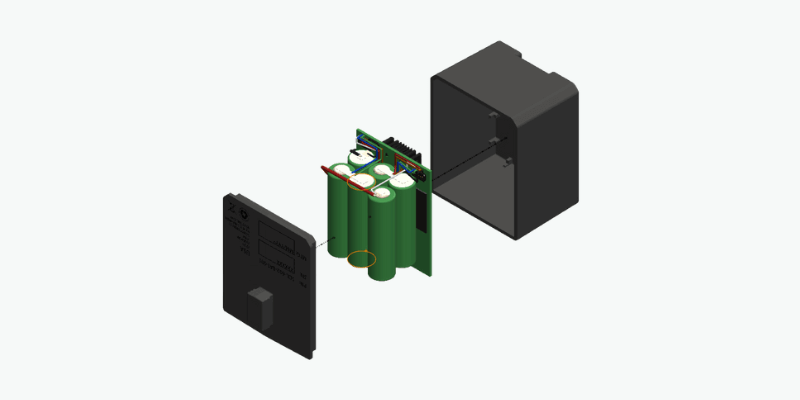

Material entwerfen & Gehäuseanforderungen

Materialien beeinflussen die Haltbarkeit, das Gewicht und die Wärmeeffizienz von Produkten.

Für Gehäuse

- Aluminiumlegierungen bieten Festigkeit und bleiben gleichzeitig leicht.

- Thermoplaste wie PA66-GF30 erhöhen die Vibrationsfestigkeit und blockieren EMI.

Für das Wärmemanagement

Silikonpads oder Epoxidharze leiten die Wärme hervorragend ab.

Um das Gewicht zu reduzieren, können die NORYL-Harze von SABIC Gehäuse um 40 % leichter machen als Aluminium.

Profi-Tipp: Bevor Sie Ihr Design fertigstellen, verwenden Sie 3D-gedruckte Modelle, um Platzbeschränkungen und die Effizienz des Wärmeflusses zu bewerten.

Zertifizierungsanforderungen

Die Einhaltung der Compliance ist für den Markteintritt und den Schutz vor Verbindlichkeiten von entscheidender Bedeutung. Hier sind die Fakten:

Globale Standards

- UN38.3: Gewährleistet einen sicheren Transport.

- ISO 12405: Garantiert die Leistung der Elektrofahrzeugbatterie.

- UL 2580 (USA) und CE (EU): Schwerpunkt auf elektrischer Sicherheit.

Regionale Compliance

- In Indien schreibt BIS feuerfeste Gehäuse und EMI-Abschirmung vor.

- Chinas GB/T 31467 konzentriert sich auf die Prävention thermisches Durchgehen.

Audit-Checkliste

Stellen Sie die Abdeckung von Zertifizierungen auf Zellenebene wie IEC 62133 und Tests auf Paketebene wie Druck- und Vibrationsprüfungen sicher.

Abschluss

Kundenspezifische Batteriepacks erfordern einen Ansatz auf Systemebene.

- Priorisieren Sie die Sicherheit mit starken BMS- und thermischen Designs, optimieren Sie die Leistungs-/Ladeparameter und wählen Sie Materialien aus, die Gewicht und Haltbarkeit in Einklang bringen.

- Nutzen Sie neue Technologien wie Festkörperelektrolyte und modulare Architekturen.

- Beauftragen Sie frühzeitig zertifizierte Testlabore, um die Einhaltung sicherzustellen und kostspielige Neukonstruktionen zu vermeiden.

Die Berücksichtigung dieser Faktoren hilft Ingenieuren dabei, Hochleistungspakete zu entwickeln, die den Industriestandards entsprechen.