Lithium batteries power our smartphones, electric vehicles, and more. Without this technology, we’d be tethered to outlets.

In this article, we will explain how lithium batteries are made, covering the materials, manufacturing, and assembly process.

What Are Lithium-Ion Batteries?

Lithium-ion batteries are rechargeable power sources that use lithium ions to generate voltage. They are among the most energy-dense and long-lifespan rechargeable battery options.

Six different types of lithium batteries exist. Here at Holo Battery, we mainly use NCM and LiFePO4 chemistry.

What Materials Are Needed to Make a Lithium Battery?

Lithium batteries primarily consist of the following materials:

Lithium Battery Cells

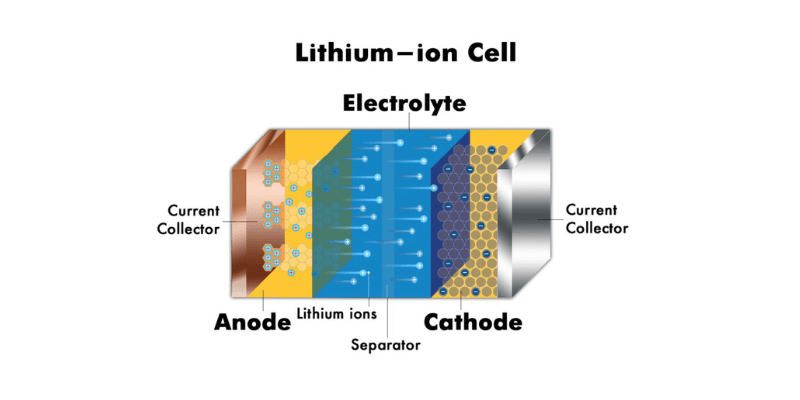

Lithium batteries in solar systems, EVs, and RVs are made of many smaller individual cells, each with an anode, cathode, and electrolyte. Manufacturers link these cells together to create the required power output.

Batteries generate power as electrons move from the anode through the electrolyte to the cathode. The anode is an oxidizing metal, and the cathode is typically a lithium oxide. The electrolyte, a lithium salt solution, supplies the excess electrons for the battery to function.

Electronics and Components

Individual battery cells connect to form a larger, more powerful battery pack through wires and terminals. The cells’ positive and negative ends link via copper and aluminum components, allowing electrons to flow smoothly.

Each battery pack also contains a Battery Management System (BMS) that monitors the pack’s temperature and the charging/discharging of individual cells.

Battery Housing

The battery housing is a critical element – it protects the batteries from exposure to outside elements that might interfere with the battery’s function. Composite materials are lightweight and resistant to fire, crash damage, and corrosion.

How Are Lithium Batteries Made?

The manufacturing process for lithium batteries is rigorous, from cell production to battery pack assembly, to ensure safety and reliability.

Cell Production

Lithium battery cells are produced through a series of steps:

1. Material Preparation: The raw materials (cathode and anode materials, electrolyte, separator, etc.) need preparation and processing before mixing. This involves steps like purification, grinding, and calcination.

2. Mixing: Active material, conductive additives, binders, and solvents are combined to create a slurry.

3. Coating: The slurry is coated onto a current collector foil and dried to form a porous electrode coating.

4. Cutting: The coated electrode is cut into slices using a roller slitting machine.

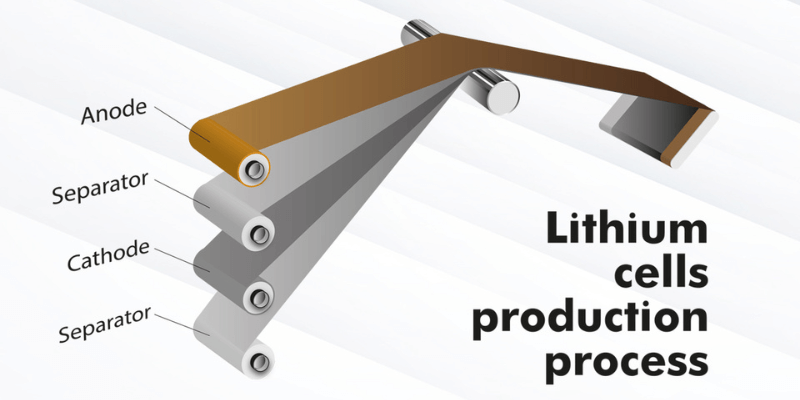

5. Stacking or winding: The anode, cathode, and separator are either stacked or wound into a spiral, depending on the battery type.

6. Marking: The positive and negative sides are marked.

7. Injecting electrolyte: A lithium salt solution is injected into the battery.

8. Sealing: The battery cell is sealed and ready for use.

9. Formation: After sealing, the battery undergoes a “formation” process to activate the materials and stabilize the cell’s performance. This involves charging and discharging cycles.

Battery Pack Assembly

Now, let’s examine how battery packs are made.

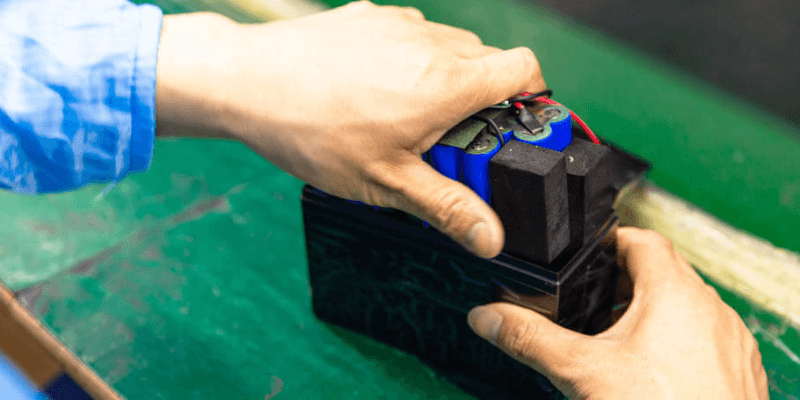

The manufacturer welds cells to plates on both the anode and cathode sides, then assembles them into packs. They test and match the packs to form the desired amp-hours.

Next, they assemble the packs into a case, connect them to the BMS, and test the full battery to ensure safety and reliability.

The Importance of Manufacturing Quality

Ensuring a safe, high-performing battery requires strict process.

Lithium batteries pose major safety risks, as faulty manufacturing or improper use can trigger thermal runaway – a fire that’s hard to extinguish.

Subpar batteries also suffer performance issues.

Therefore, it’s important to get a trusted battery manufacturer.

At Holo Battery, we maintain strict quality standards, thoroughly testing cells and batteries during manufacturing. Our proprietary battery management system prevents dangerous operating conditions.

FAQs

Are Lithium Batteries Recyclable?

Used batteries can be recycled to reuse lithium, but the processes are still new, challenging, and costly. Many lithium batteries also have not reached their end of life, so recycling is not yet necessary. As more batteries require recycling, improving the processes is crucial for a sustainable future and to avoid mining Earth’s resources. Companies are finding better ways to reuse batteries.

Can lithium-ion batteries explode?

Yes, lithium-ion batteries can explode under certain conditions like overcharging, overheating, manufacturing defects, and external damage. So safety measures during assembly, such as spot welding and incorporating a BMS, are vital to prevent battery failure.

How long do lithium-ion batteries last?

Generally, lithium-ion batteries can last 2 to 5 years with normal use. Proper care can extend their lifespan even further.

Related Articles: