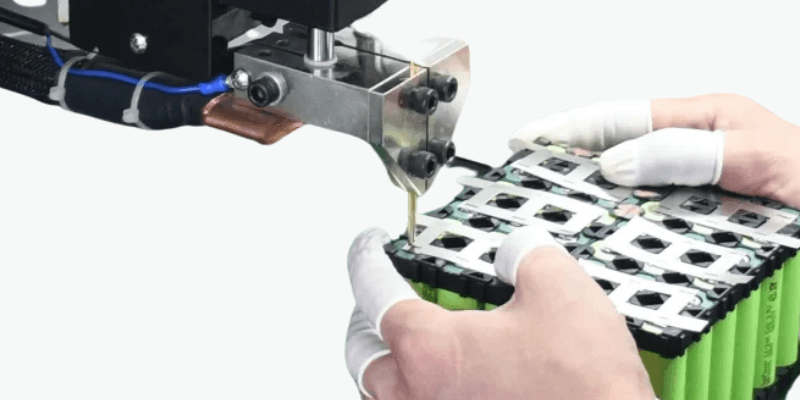

ช่างเชื่อมจุดแบตเตอรี่เป็นสิ่งจำเป็นสำหรับการสร้างการเชื่อมต่อที่มั่นคง ชุดแบตเตอรี่ลิเธียม- มันเชื่อมต่อชิ้นส่วนโลหะโดยใช้ความร้อนและความดันโดยไม่ทำลายเซลล์ ในการเชื่อมสปอตเชื่อมแบตเตอรี่ลิเธียมอย่างปลอดภัยและมีประสิทธิภาพคู่มือทีละขั้นตอนนี้จะนำคุณผ่านเทคนิคและอุปกรณ์ที่สำคัญทั้งหมดที่คุณต้องการ

กระบวนการเชื่อมจุดแบตเตอรี่

ช่างเชื่อมจุดแบตเตอรี่คืออะไร?

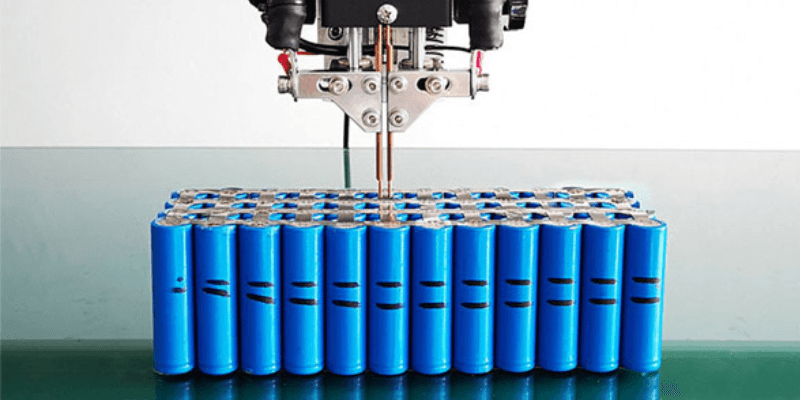

Welderr จุดแบตเตอรี่ลิเธียม (หรือเครื่องเชื่อมความต้านทาน) ใช้กระแสไฟฟ้าที่ควบคุมเพื่อสร้างความร้อนในท้องถิ่น ขั้ว-

ซึ่งแตกต่างจากการบัดกรีแบบดั้งเดิมมันช่วยลดความเครียดจากความร้อนในแบตเตอรี่รักษาความสมบูรณ์และการนำไฟฟ้าของพวกเขา รุ่นที่ทันสมัยรวมถึงการควบคุมอัตโนมัติการตรวจสอบปัจจุบันแบบเรียลไทม์และสัญญาณเตือนความปลอดภัยเพื่อป้องกันการเชื่อมหรือไฟที่ผิดพลาด

พื้นฐานของการเชื่อมเฉพาะจุด

การเชื่อมแบบสปอตใช้ความร้อนด้วยความร้อน: อิเล็กโทรดกดพื้นผิวโลหะเช่นแถบนิกเกิลกับขั้วแบตเตอรี่ในขณะที่พัลส์กระแสสูง (2-10 มิลลิวินาที) ละลายจุดสัมผัส สิ่งนี้เป็นข้อต่อที่แข็งแรงและต้านทานต่ำซึ่งมีความสำคัญต่อความเสถียรของแบตเตอรี่

สำหรับแบตเตอรี่ลิเธียมความแม่นยำเป็นสิ่งสำคัญในการป้องกันความเสียหายต่อภายใน ส่วนประกอบ หรือ หนีความร้อน-

อุปกรณ์ที่จำเป็นสำหรับการเชื่อมแบบสปอต

ในการใช้แบตเตอรี่ลิเธียมสปอตคุณต้องใช้เครื่องมือต่อไปนี้:

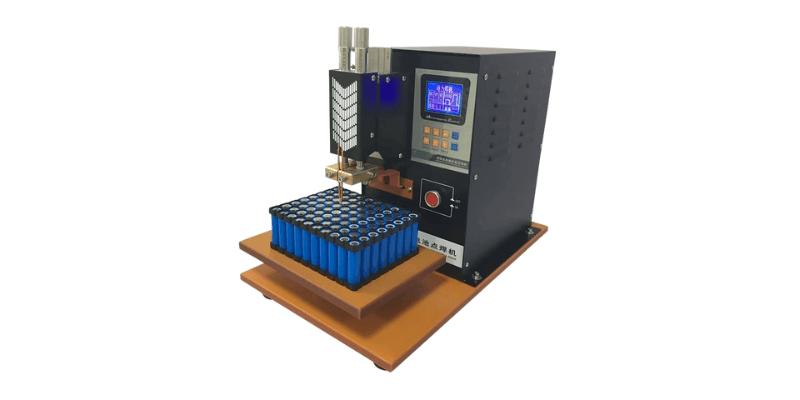

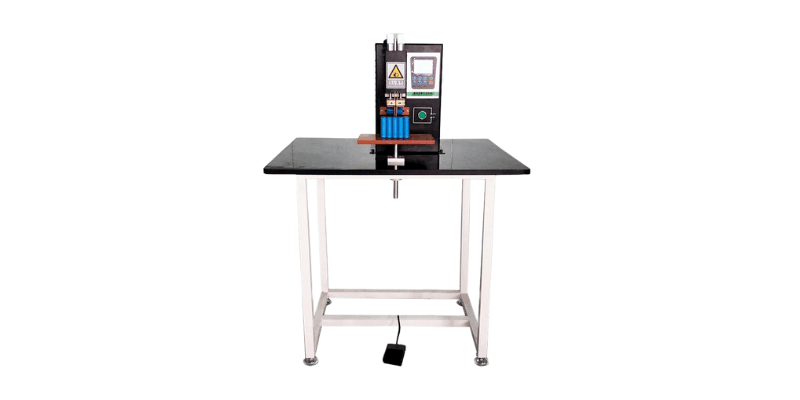

1. จุดเชื่อม: เครื่องมือหลักนี้สร้างกระแสไฟฟ้าและใช้แรงดันสำหรับการเชื่อม

– ประเภท: ช่างเชื่อมมือถือเหมาะสำหรับงานขนาดเล็กในขณะที่เครื่องติดตั้งที่ติดตั้งจะดีกว่าสำหรับโครงการขนาดใหญ่

– การตั้งค่าพลังงาน: การตั้งค่าที่ปรับได้ป้องกันความเสียหายต่อแบตเตอรี่

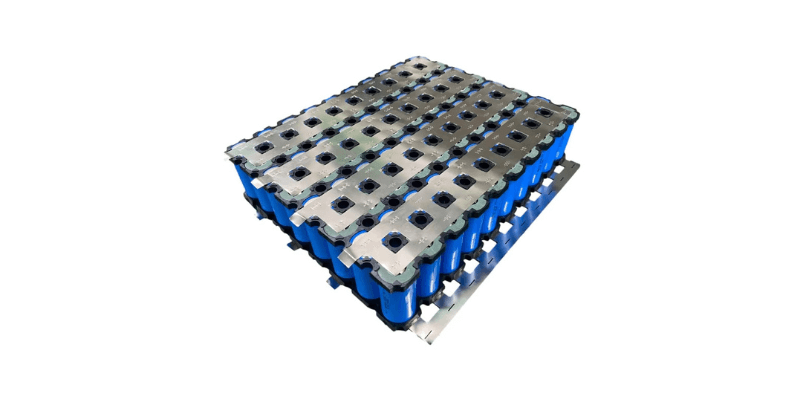

2. แถบนิกเกิล: ใช้เพื่อเชื่อมต่อเซลล์แบตเตอรี่

– คุณภาพ: แถบที่มีความบริสุทธิ์สูงดำเนินการไฟฟ้าได้ดีและแข็งแกร่ง

– ขนาด: เลือกความหนาที่เหมาะสม แถบหนาต้องการพลังงานมากขึ้น

3. อุปกรณ์ความปลอดภัย: โดยเฉพาะอย่างยิ่งสำหรับผู้เริ่มต้น

– ถุงมือ: สวมถุงมือทนความร้อนเพื่อป้องกันมือ

– แว่นตา: ใช้แว่นตานิรภัยเพื่อป้องกันประกายไฟ

– เสื้อผ้า: เลือกใช้แขนยาวและหลีกเลี่ยงผ้าสังเคราะห์ที่สามารถละลายได้

4. ที่ยึดแบตเตอรี่: รักษาเซลล์แบตเตอรี่ให้เสถียรในระหว่างการเชื่อม ตรวจสอบให้แน่ใจว่าพอดีกับเซลล์เฉพาะของคุณ

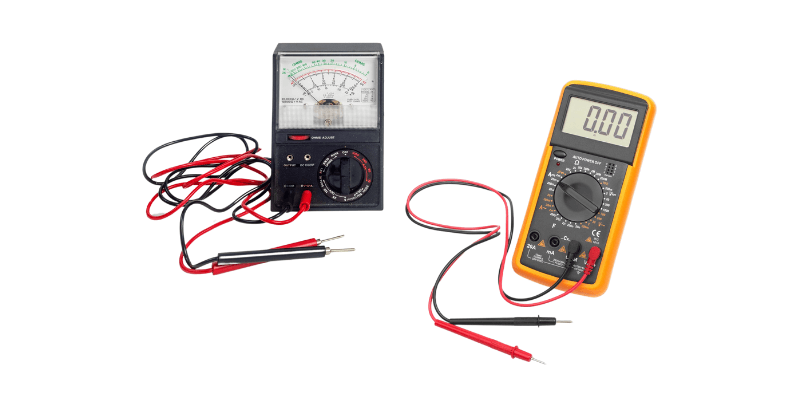

5. มัลติมิเตอร์: ตรวจสอบการเชื่อมต่อเพื่อให้แน่ใจว่าค่าการนำไฟฟ้าที่เหมาะสมหลังจากการเชื่อม

เตรียมแบตเตอรี่ลิเธียมเชื่อมแบตเตอรี่

ข้อควรระวังด้านความปลอดภัย

ก่อนที่จะมีแบตเตอรี่เชื่อมลิเธียมให้จัดลำดับความสำคัญความปลอดภัยด้วยมาตรการเหล่านี้:

- สวมใส่อุปกรณ์ป้องกันเช่นถุงมือทนความร้อนแว่นตานิรภัยและเสื้อผ้าที่ไม่ติดไฟ

- ตรวจสอบให้แน่ใจว่ามีการระบายอากาศที่ดีเพื่อป้องกันควันที่เป็นอันตราย

- ตรวจสอบจุดเชื่อมและเครื่องมือของคุณสำหรับความเสียหายก่อนเริ่ม

- เก็บเครื่องดับเพลิงไว้ใกล้ ๆ ในกรณีที่สิ่งต่าง ๆ ร้อนขึ้น

- ยังคงตื่นตัวเพื่อป้องกันอุบัติเหตุ

เตรียมพื้นที่ทำงาน

สำหรับเซสชันการเชื่อมจุดที่ราบรื่นตั้งค่าพื้นที่ทำงานของคุณดังนี้:

1. ทำความสะอาดพื้นผิวการทำงาน: ชัดเจนจากโต๊ะทำงานของคุณเพื่อจัดระเบียบ

2. หลีกเลี่ยงวัสดุไวไฟ: ลบรายการที่ติดไฟได้ในบริเวณใกล้เคียงเพื่อลดความเสี่ยงจากไฟไหม้

3. ที่ยึดแบตเตอรี่รักษาความปลอดภัย: ทำให้ตัวยึดแบตเตอรี่เสถียรเพื่อป้องกันไม่ให้เปลี่ยนในขณะที่คุณทำงาน

4. อุปกรณ์การเชื่อมตำแหน่ง: รักษาจุดเชื่อมและเครื่องมือของคุณให้อยู่ในระดับที่เข้าถึงได้ง่าย

การเตรียมแบตเตอรี่ลิเธียม

การเตรียมแบตเตอรี่ลิเธียมที่เหมาะสมเป็นพื้นฐานสำหรับการเชื่อมจุดที่ประสบความสำเร็จ ทำตามขั้นตอนเหล่านี้:

1. ทำความสะอาดพื้นผิวแบตเตอรี่: ใช้ผ้าที่สะอาดและแห้งเพื่อเช็ดพื้นผิวเซลล์แบตเตอรี่กำจัดสิ่งสกปรกและสารตกค้าง

2. จัดเรียงเซลล์แบตเตอรี่: จัดตำแหน่งเซลล์ในการกำหนดค่าที่ต้องการเพื่อให้แน่ใจว่าพวกเขาจะจัดตำแหน่งและเว้นระยะสำหรับการเชื่อมอย่างเหมาะสม

3. ตรวจสอบแถบนิกเกิล: ตรวจสอบแถบนิกเกิลสำหรับข้อบกพร่องและยืนยันว่าพวกเขามีขนาดและความหนาที่ถูกต้อง

4. การเชื่อมต่อที่ปลอดภัย: ตรวจสอบว่าการเชื่อมต่อระหว่างเซลล์แบตเตอรี่และแถบนิกเกิลนั้นปลอดภัยและไม่มีสิ่งกีดขวาง

ขั้นตอนการเชื่อมแบตเตอรี่สำหรับแบตเตอรี่ลิเธียม

การตั้งค่าจุดเชื่อมจุดเชื่อม

หากต้องการพบแบตเตอรี่ลิเธียมเชื่อมได้สำเร็จให้ตั้งค่าและปรับเทียบจุดเชื่อมจุดของคุณอย่างเหมาะสม นี่คือวิธี:

1. การตั้งค่าพลังงาน: ปรับพลังงานตามความหนาของแถบนิกเกิลและประเภทเซลล์แบตเตอรี่

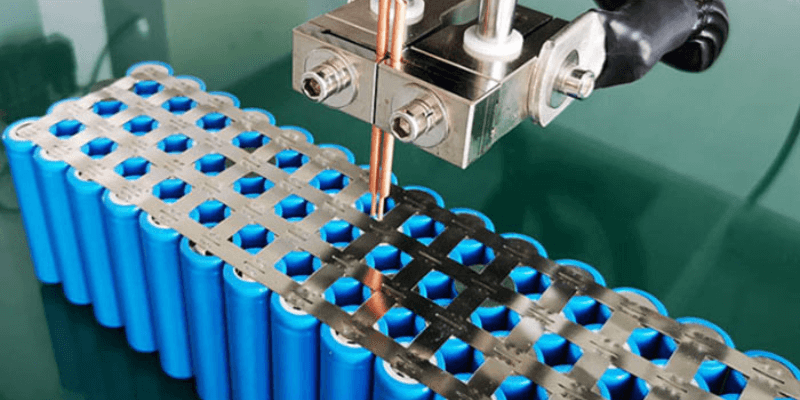

2. การวางตำแหน่งอิเล็กโทรด: ตรวจสอบแล้ว ขั้วไฟฟ้า ติดต่อได้ดีกับทั้งแถบนิกเกิลและเซลล์แบตเตอรี่

3. การสอบเทียบ: ทำตามคำแนะนำของผู้ผลิตสำหรับการสอบเทียบเพื่อให้ได้รอยเชื่อมที่แม่นยำและสอดคล้องกัน

แสดงจุดเชื่อมจุด

เริ่มกระบวนการเชื่อมจุดหลังจากตั้งค่าการเชื่อมโดยทำตามขั้นตอนเหล่านี้:

1. เตรียมพื้นที่เชื่อม: วางแบตเตอรี่ลิเธียมไว้อย่างปลอดภัยในที่ยึด

2. อิเล็กโทรดตำแหน่ง: จัดตำแหน่งอิเล็กโทรดเชื่อมจุดผ่านทางแยกของแถบนิกเกิลและเซลล์แบตเตอรี่

3. ใช้แรงดัน: กดขั้วไฟฟ้าอย่างแน่นหนาเพื่อให้แน่ใจว่ามีการติดต่อที่ดี

4. เปิดใช้งานช่างเชื่อม: เปิดเครื่องเชื่อมจุดเพื่อส่งกระแสไฟฟ้าสั้น ๆ ที่รุนแรงและละลายแถบนิกเกิลเพื่อเชื่อมที่เป็นของแข็ง

5. ทำซ้ำ: ดำเนินการต่อกระบวนการนี้สำหรับแต่ละทางแยกเพื่อให้มั่นใจว่าคุณภาพการเชื่อมที่สอดคล้องกัน

ตรวจสอบรอยเชื่อม

เมื่อคุณทำการเชื่อมจุดเสร็จแล้วก็ถึงเวลาตรวจสอบความแข็งแกร่งและความน่าเชื่อถือของรอยเชื่อมเหล่านั้น นี่คือวิธีที่คุณสามารถทำได้:

- ลองดู: ตรวจสอบด้วยการเชื่อมแต่ละรอยสำหรับการหลอมรวมที่ไม่สมบูรณ์หรือจุดอ่อน

- การทดสอบ TUG: ดึงแถบนิกเกิลเบา ๆ เพื่อให้แน่ใจว่ามันติดอยู่กับเซลล์แบตเตอรี่อย่างแน่นหนา

- การทดสอบมัลติมิเตอร์: วัดความต้านทานของรอยเชื่อมด้วยมัลติมิเตอร์เพื่อยืนยันว่าพวกเขาอยู่ในช่วงเป้าหมายของคุณ

- การเสริมแรง: หากคุณพบรอยเชื่อมที่อ่อนแอหรือ subpar ให้เสริมด้วยการเชื่อมเฉพาะจุดเพิ่มเติม

เคล็ดลับสำหรับการเชื่อมจุดแบตเตอรี่

หลีกเลี่ยงความร้อนสูงเกินไป

- ใช้การเชื่อมพัลซิ่งเพื่อควบคุมความร้อน

- ตรวจสอบอุณหภูมิด้วยเซ็นเซอร์ IR

ความเข้ากันได้ของวัสดุ

เชื่อมนิกเกิลหรือเหล็กชุบนิกเกิล หลีกเลี่ยงการผสมอลูมิเนียมแค็ปเปอร์เนื่องจากความต้านทานสูง

มาตรการความปลอดภัย

- ทำงานในพื้นที่ที่มีการระบายอากาศอย่างดีเพื่อกำจัดควัน

- สวมถุงมือต่อต้านสแตติกและแว่นตา

การซ่อมบำรุง

ทำความสะอาดขั้วไฟฟ้าเป็นประจำเพื่อป้องกันการสะสมออกซิเดชัน

คำถามที่พบบ่อย

การประสานแบตเตอรี่ลิเธียมประสานกันหรือไม่?

ไม่เตารีดบัดกรีร้อนเกินไปและสามารถทำลายส่วนประกอบหรือทำให้เกิดความร้อนสูงเกินไป การเชื่อมแบบสปอตเป็นตัวเลือกที่ดีกว่า

ช่างเชื่อมสปอตแบตเตอรี่ใช้งานได้อย่างไรสำหรับแบตเตอรี่ลิเธียม?

มันใช้กระแสไฟฟ้าที่ควบคุมผ่านขั้วไฟฟ้าละลายบัดกรีเพื่อเข้าร่วมเทอร์มินัลและตัวเชื่อมต่อโดยไม่ทำให้เซลล์ยุ่งเหยิง

ฉันสามารถมองเห็นแบตเตอรี่ลิเธียมประเภทต่าง ๆ เข้าด้วยกันได้หรือไม่?

อย่าผสมแบตเตอรี่ประเภทต่าง ๆ เช่น Li-ion กับ LIFEPO4 หรือความสามารถ การทำเช่นนั้นสามารถนำไปสู่การกระจายปัจจุบันที่ไม่สม่ำเสมอและทำให้เกิดความไม่สมดุล